Petroleum processing treatment equipment in petro-chemical machinery field

A technology for petrochemical and processing equipment, which is applied in mixers, chemical instruments and methods, shaking/oscillating/vibrating mixers, etc., and can solve problems such as unsatisfactory petroleum processing, insufficiently uniform liquid mixing, and unsatisfactory mixing effects. Low cost, simple operation, uniform mixing and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The petroleum processing equipment in the petrochemical machinery field of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

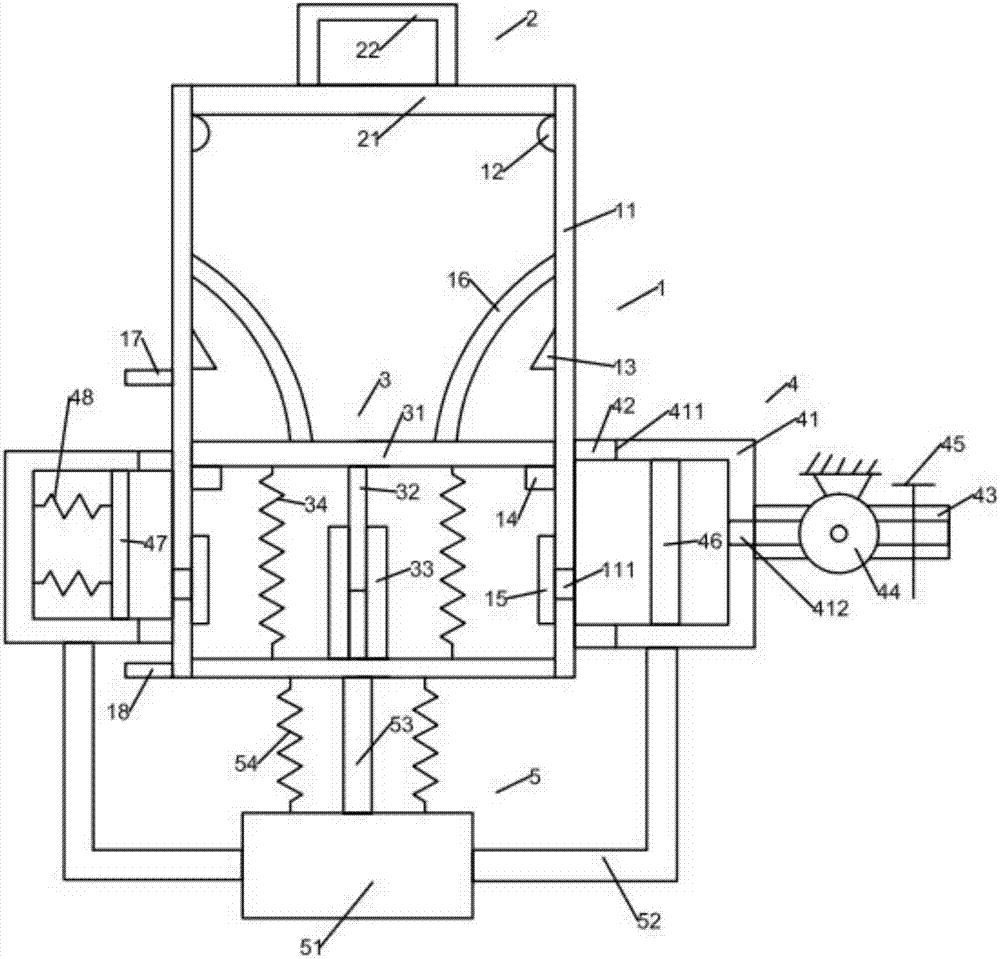

[0018] Such as figure 1 As shown, the petroleum processing equipment in the field of petrochemical machinery of the present invention includes a first frame device 1, a cover device 2 arranged on the upper end of the first frame device 1, a cover device located in the first frame device 1 The concentrating plate device 3 , the second frame device 4 arranged at the lower end of the first frame device 1 , and the electric cylinder device 5 located below the second frame device 4 .

[0019] Such as figure 1 As shown, the first frame device 1 includes a first frame 11, first support blocks 12 accommodated in the left and right sides of the first frame 11, and first support blocks 12 below the first support block 12. Restricting block 13, second restricting block 14 located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com