3D printing device and printing method for integrated manufacturing of functionally graded materials and structures

A functionally graded material and 3D printing technology, which is applied in the direction of manufacturing auxiliary devices, additive processing of mixtures of solid materials and liquid materials, processing and manufacturing, etc., can solve problems such as uneven mixing of component materials, high viscosity, and short time consumption , to improve printing efficiency and stability, realize high-efficiency and low-cost manufacturing, and achieve high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

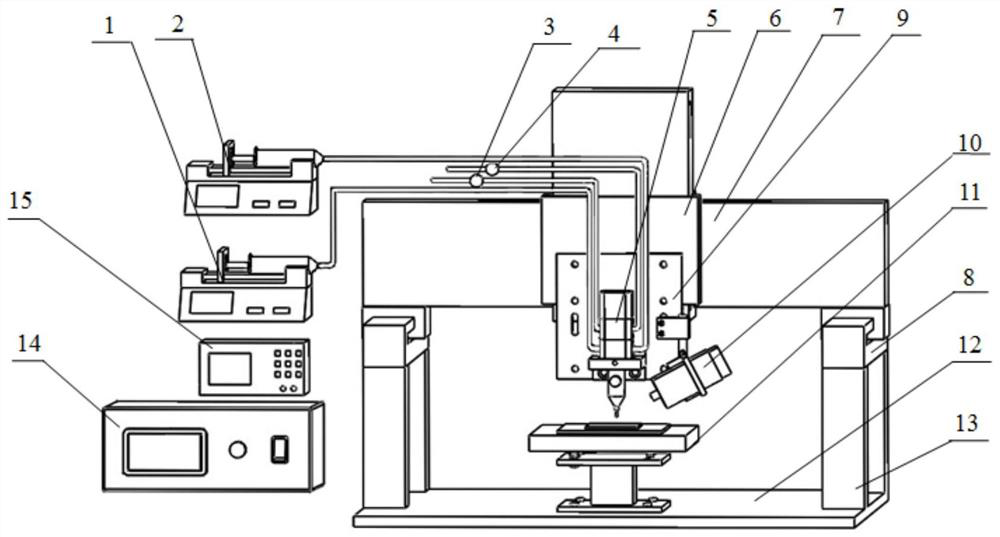

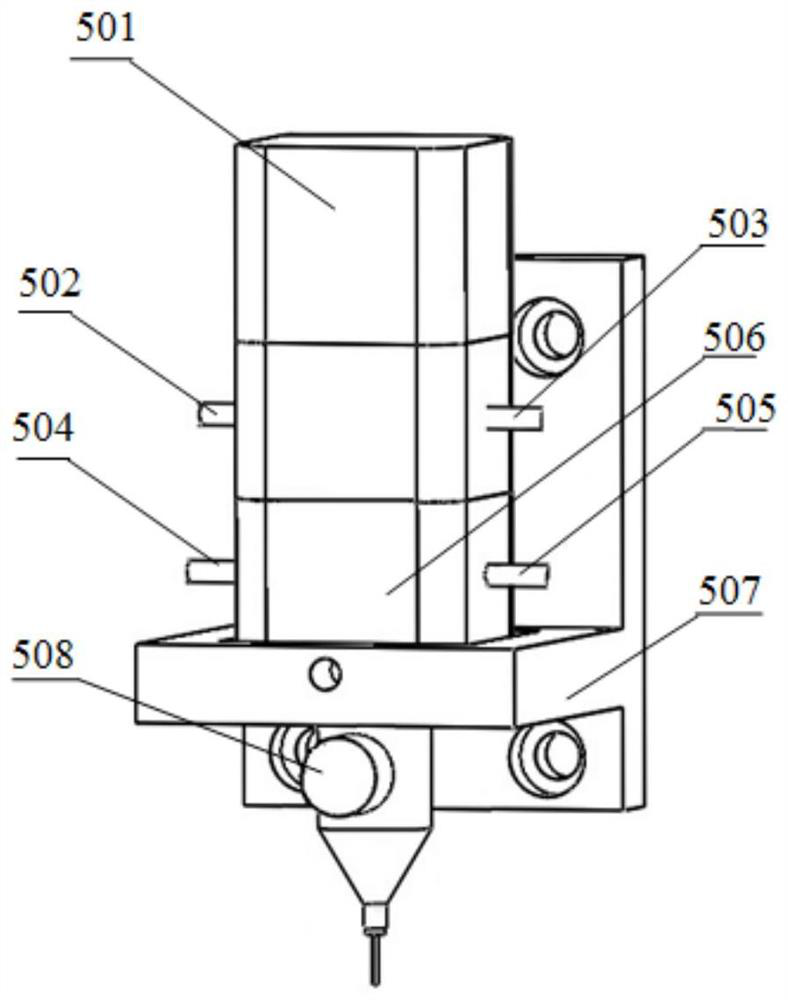

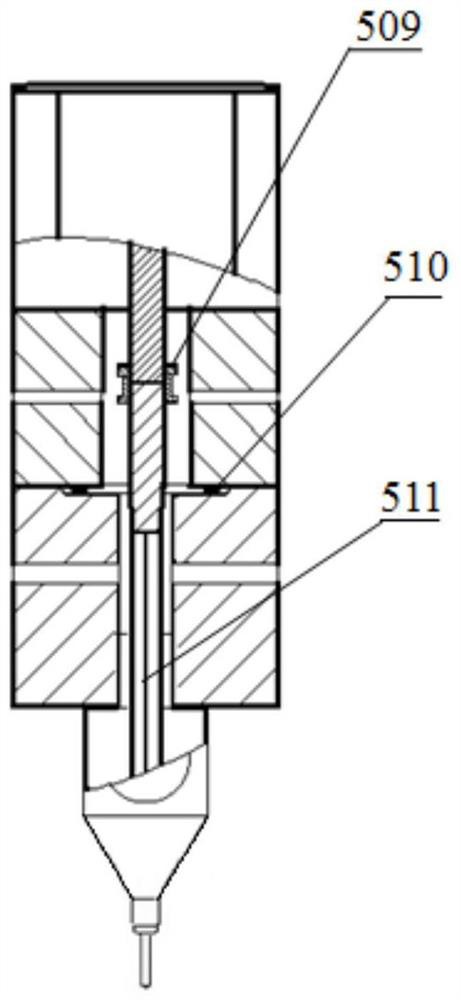

[0082] figure 1 It is a schematic structural diagram of a functional gradient device based on active multi-material mixing according to an embodiment of the present invention, which includes: a feeding module I1, a feeding module II2, a gas circuit system I (positive pressure gas circuit) 3, and a gas circuit system II (negative pressure). Air path) 4, print nozzle module 5, Z-axis table 6, X-axis table 7, Y-axis table 8, which together form XYZ three-axis motion module, bracket 9, upper curing module 10, printing platform 11, bottom plate 12 , rack 13 , high voltage DC power supply 14 , control module 15 .

[0083] Specifically, the feeding module I1 and the feeding module II2 are respectively connected with the printing nozzle module 5, the printing nozzle module 5 is fixed on the bracket 9, and the bracket 9 is fixed on the Z-axis worktable; the Z-axis worktable 6 , X-axis worktable 7 and Y-axis worktable 8, together form an XYZ three-axis motion module, the XYZ three-axis...

Embodiment 2

[0118] Further, in this embodiment, the gas circuit system II 4 is replaced with a normal pressure gas circuit 4, and its working air pressure is 0pa.

[0119] The present invention uses PDMS / SiO 2 The functionally graded substrate is an embodiment, and the working method of the integrated manufacturing of continuous functionally graded materials and structures is realized, and the specific process steps are described:

[0120] Step 1: Print data file preparation. Determine the functionally graded substrate from one side (outer surface) to the other (inner) SiO based on the structural requirements of the print 2 The density of 0%-50% changes continuously, and the printing height of each layer is determined to be 0.2mm, and the line spacing is set to 0.3mm.

[0121] Step 2: Pre-print processing. The PDMS elastomer and the curing agent were uniformly mixed at a ratio of 10:1 and evacuated to produce pure PDMS (printing material I). The configuration of the variable-component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com