Powder-liquid mixing equipment

A mixing equipment and powder-liquid technology, which can be used in mixers, mixing methods, mixers with rotary stirring devices, etc., can solve problems such as poor mixing uniformity of powder and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

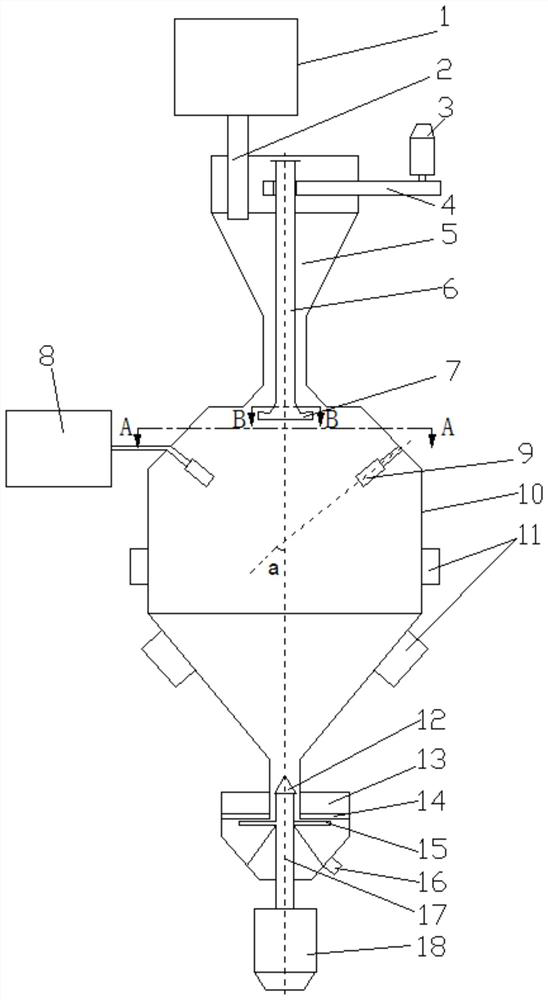

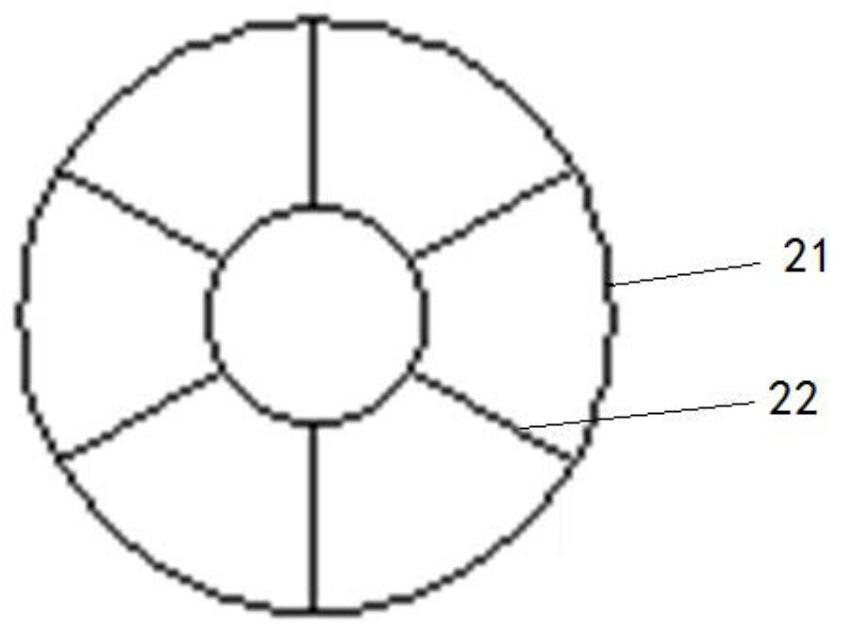

[0042] As an embodiment, the driving device includes a rotating shaft 17 and a second driving motor 18, the rotating shaft 17 extends through the body of the unloading bin into the unloading cavity 13, and the rotating The shaft 17 is arranged through the middle part of the turntable body 20, and the bottom end of a section of the rotating shaft 17 located outside the discharge bin is connected to the second drive motor 18, and the rotating shaft 17 is located at the inside of the discharging bin. A splitter cone 12 is arranged at the top of one section, and the splitter cone 12 is a cone-shaped body, and the splitter cone 12 is used for splitting the powder-liquid mixture entering the discharge chamber 13 .

[0043] As an implementation, such as figure 1 As shown, the top of the discharge chamber 13 is provided with a fixed plate 14, the fixed plate 14 is located above the turntable body 20 and spaced apart from the turntable body 20, the periphery of the fixed plate 14 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com