Multifunctional sintering blowing ring circular cooler

A ring cooler and multi-functional technology, applied in the field of metallurgical equipment, can solve the problems of large dust, reduce the efficiency of waste heat utilization, and pollute the surrounding environment, and achieve the effects of simple sealing structure, improved sealing effect, and increased ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings.

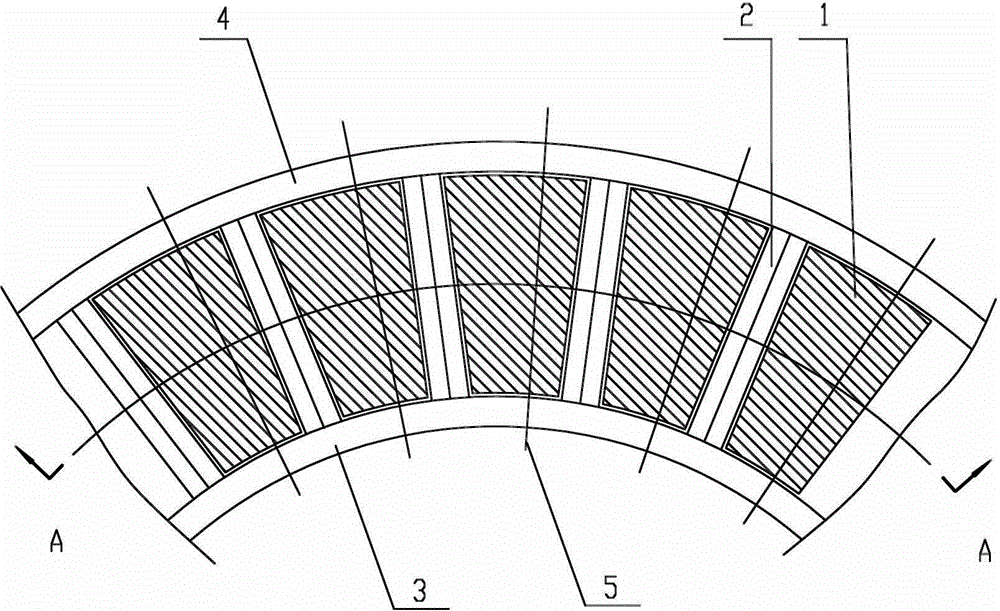

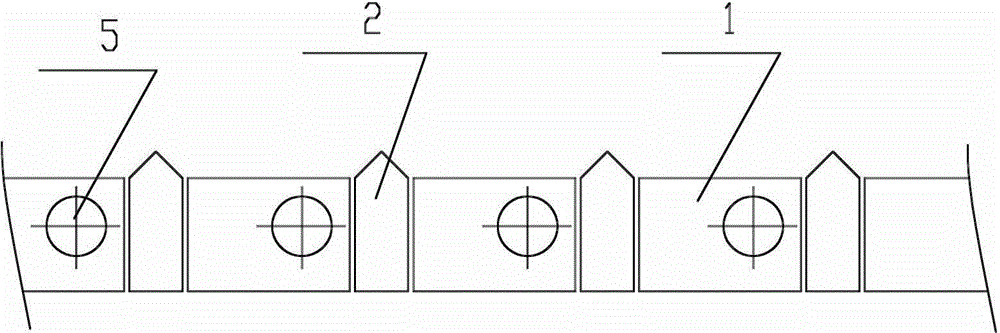

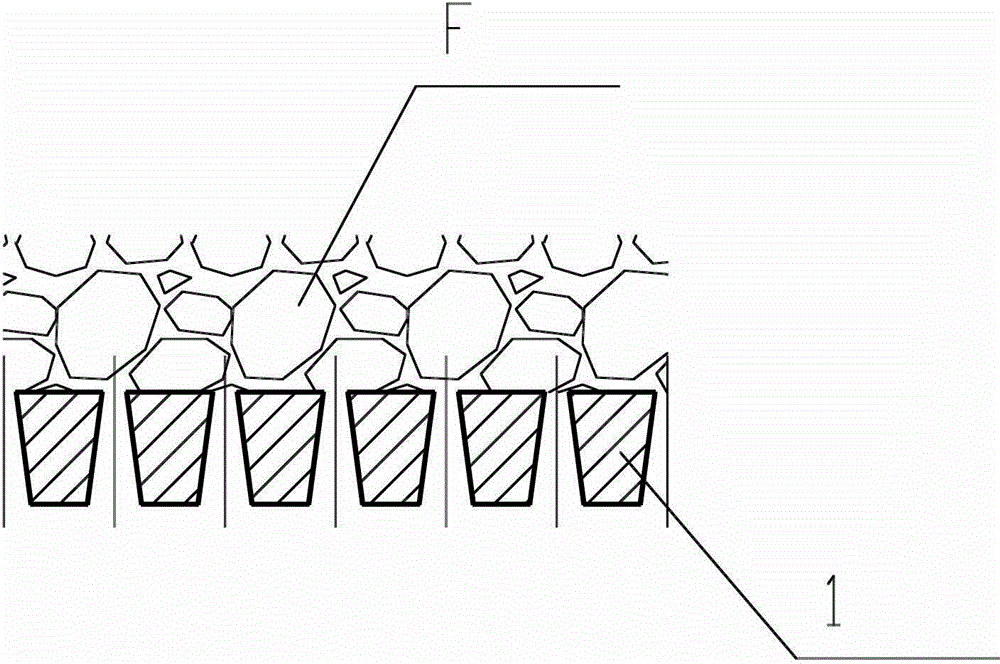

[0059] Such as Figure 4-20 As shown, the multifunctional sintering blast ring type annular cooler of the present invention comprises an annular cooler frame 12, an inner support roll 23 and an outer support roll 14 connected to the annular cooler frame 12, through the inner support roll 23 and The inner slewing frame 4 and the outer slewing frame 3 supported by the outer support roller 14 are arranged between the inner slewing frame and the outer slewing frame and the connecting beam 2 connecting the two is arranged between the inner slewing frame 4 and the outer slewing frame 3 The trolley 1, the trolley shaft 5 connecting the trolley 1 with the inner slewing frame 4 and the outer slewing frame 3, and the inner trolley fence 21 and the outer trolley fence respectively connected with the inner slewing frame 4 and the upper part of the outer slewing frame 3 The plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com