Bidirectional shock wave resistant valve

An anti-shock wave and valve body technology, applied in the field of shock wave valves, can solve the problems of small ventilation volume, etc., and achieve the effects of enhanced ventilation capacity, simple principle and strong replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The existing one-way anti-shock wave valves with large ventilation volume on the market cannot adapt to the environment of two-way shock waves, and the ventilation volume of valves that can play a two-way anti-shock wave is relatively small, so it is urgent to introduce a unit area ventilation Strong bi-directional anti-shock wave valve.

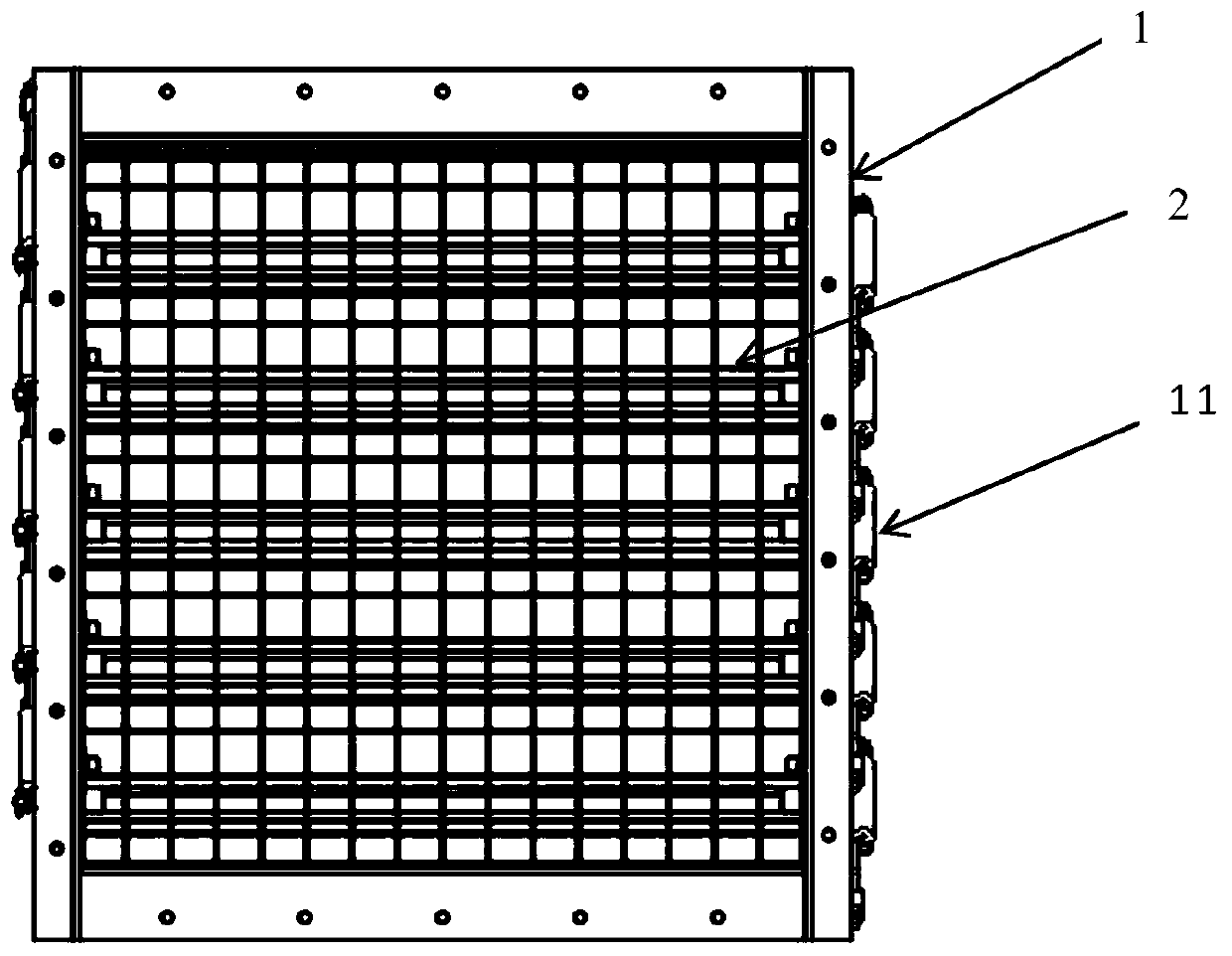

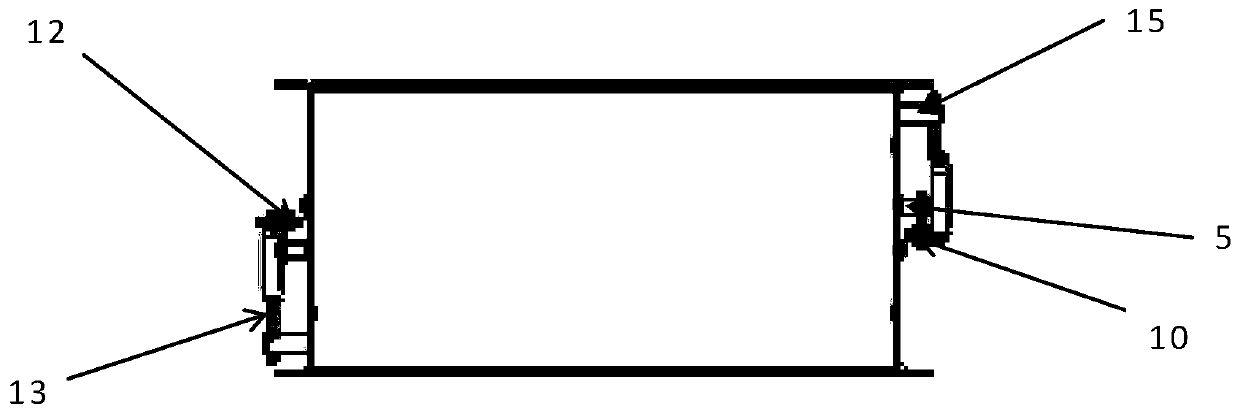

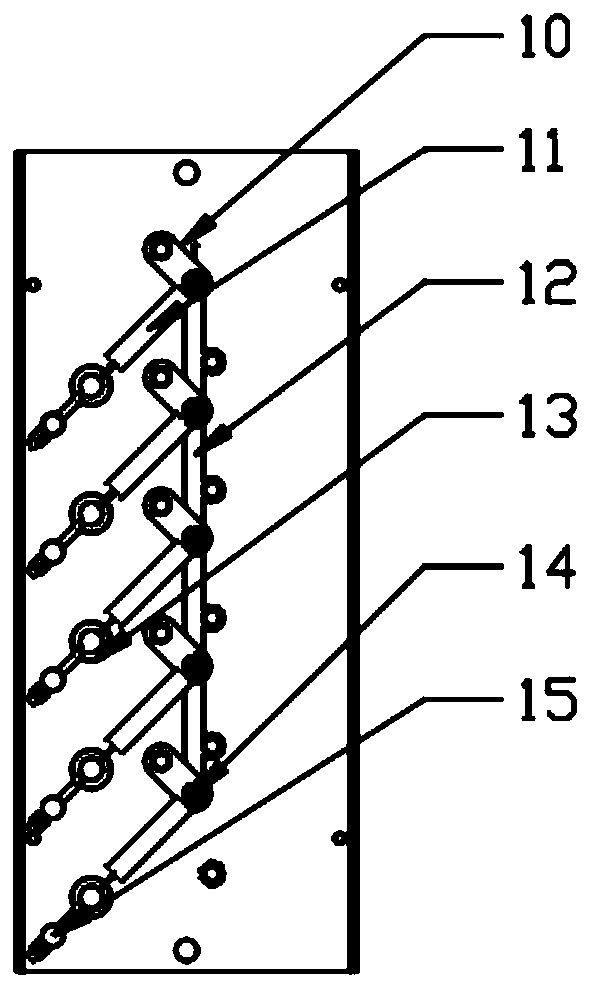

[0053] figure 1 It is a schematic diagram of the front view of the two-way anti-shock wave valve of the present invention; figure 2 It is a top view schematic diagram of the two-way anti-shock wave valve of the present invention; image 3 It is a schematic side view of the two-way anti-shock wave valve of the present invention; Figure 4 It is a schematic cross-sectional view of the two-way anti-shock wave valve of the present invention; Figure 5 It shows the direction of normal ventilation and shock wave of the two-way anti-shock wave valve of the present invention; Figure 6It is a schematic diagram of the closed state of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com