Blade type large-wind-volume impact wave resisting valve

An anti-shock wave and large air volume technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of inappropriate modular anti-knock valves, large valve sizes, and small ventilation areas, so as to save energy and increase the ventilation area. Large, strong ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

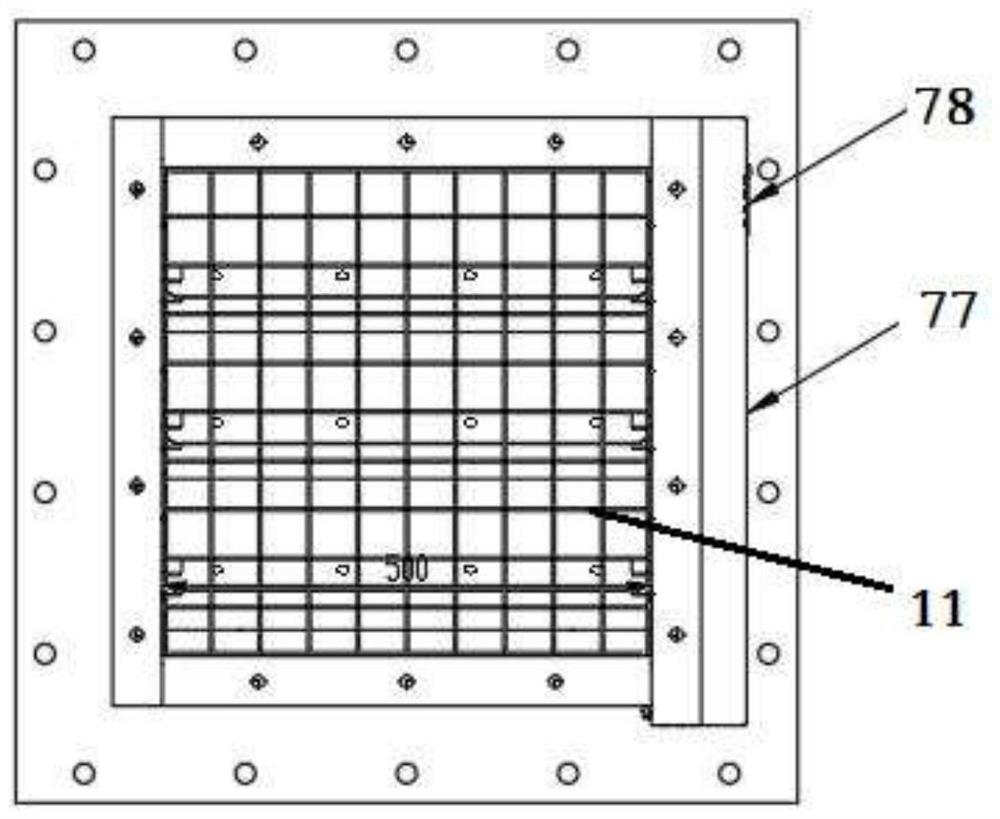

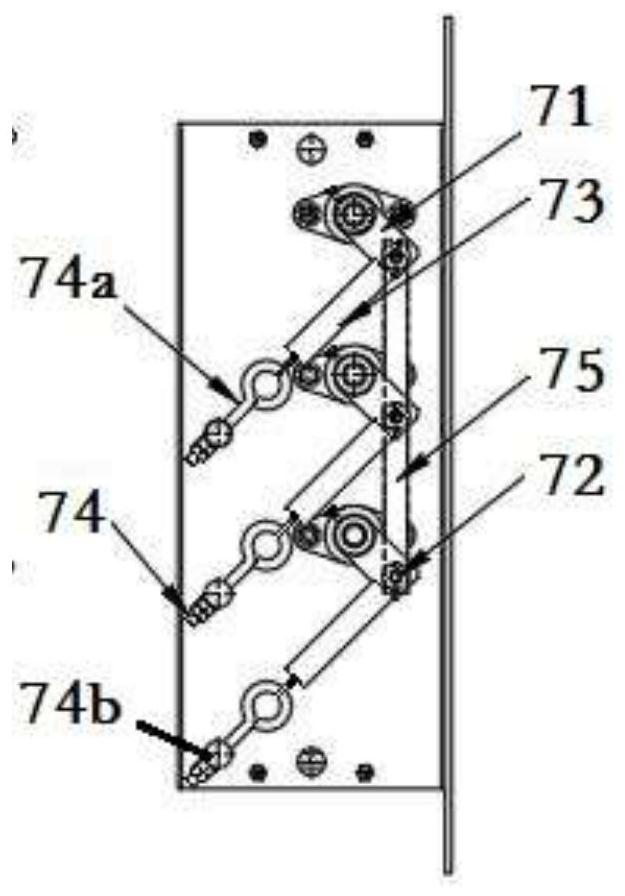

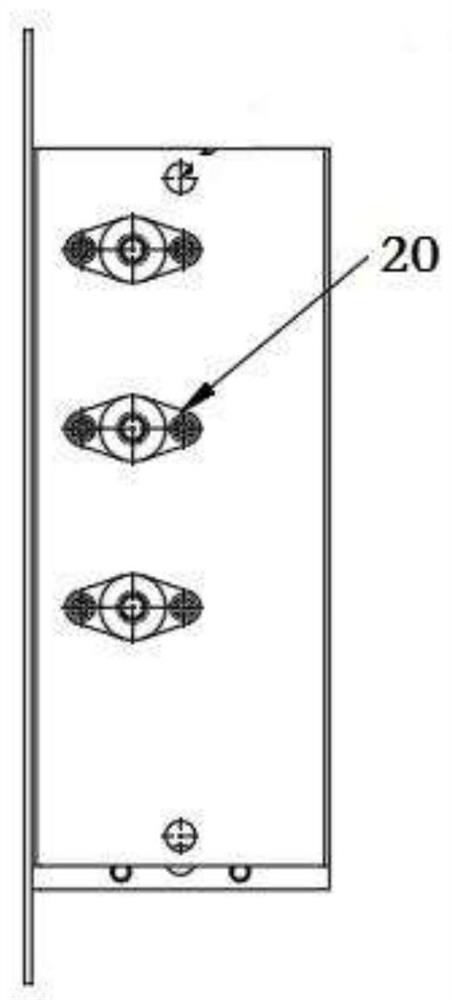

[0051] refer to Figure 1 to Figure 6 , The vane type large air volume anti-shock wave valve of the present invention includes a frame 10 , a bearing 20 , a rotating shaft 30 , a valve leaf 40 and a valve leaf stopper 50 . The frame 10 has a rectangular shape. Bearings 20 are fixed on both ends of the frame 10 outside. The rotating shaft 30 is installed in the frame 10 through the bearing 20. There are multiple rotating shafts 30 arranged in parallel at equal intervals from top to bottom, and the multiple rotating shafts 30 are linked with each other. The valve leaf 40 is fixed on the rotating shaft 30 and rotates together with the rotating shaft 30 . The valve leaf stopper 50 includes a valve leaf front stopper 51 and a valve leaf rear stopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com