Biomass semi-gasification stove

A semi-gasification, biomass technology, applied in coke ovens, household stoves/stoves, climate sustainability, etc., can solve the problems of uneven distribution of secondary air intake, low combustion efficiency, high production costs, and increase energy The effect of utilizing thermal efficiency, improving combustion efficiency, and light product shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

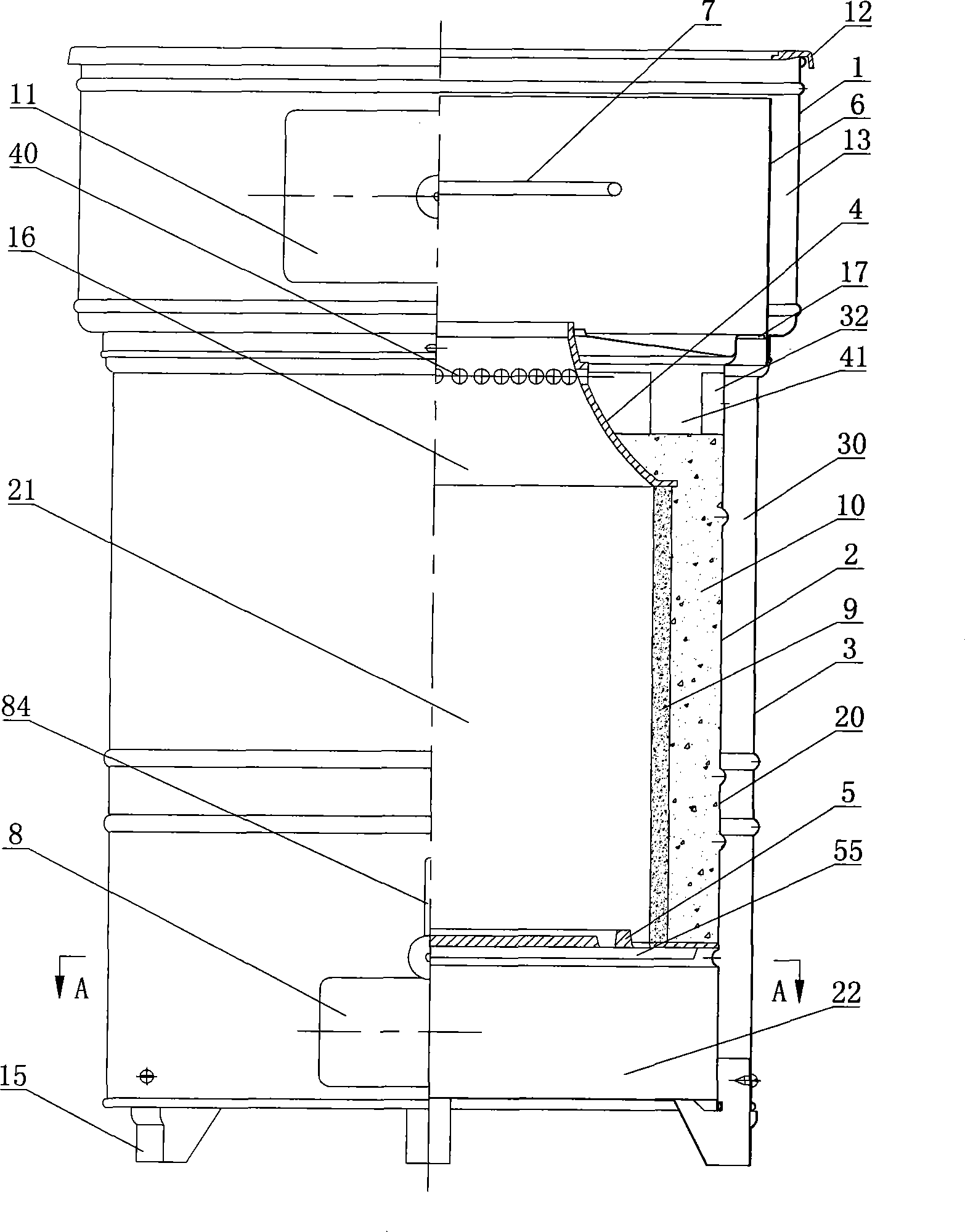

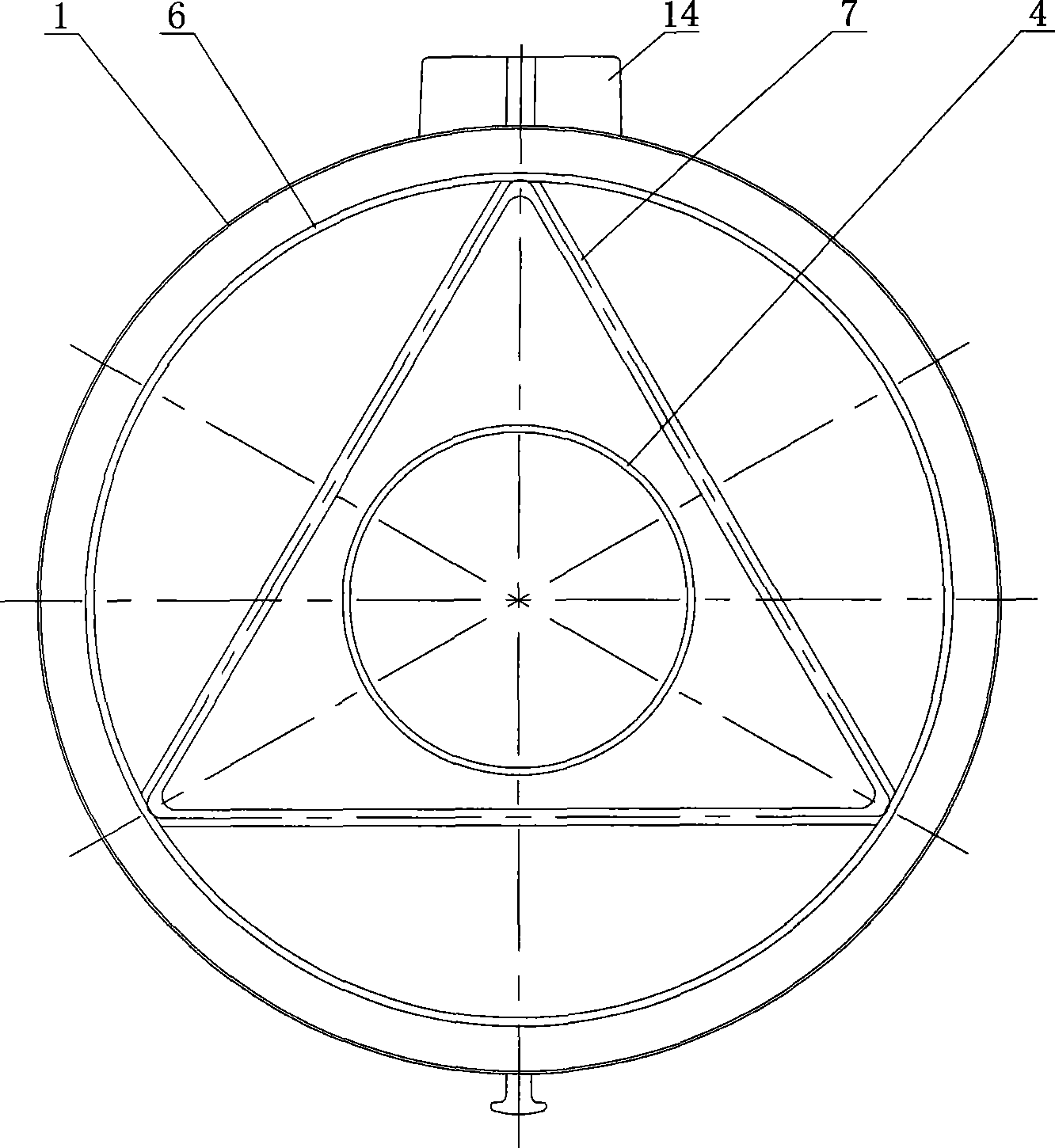

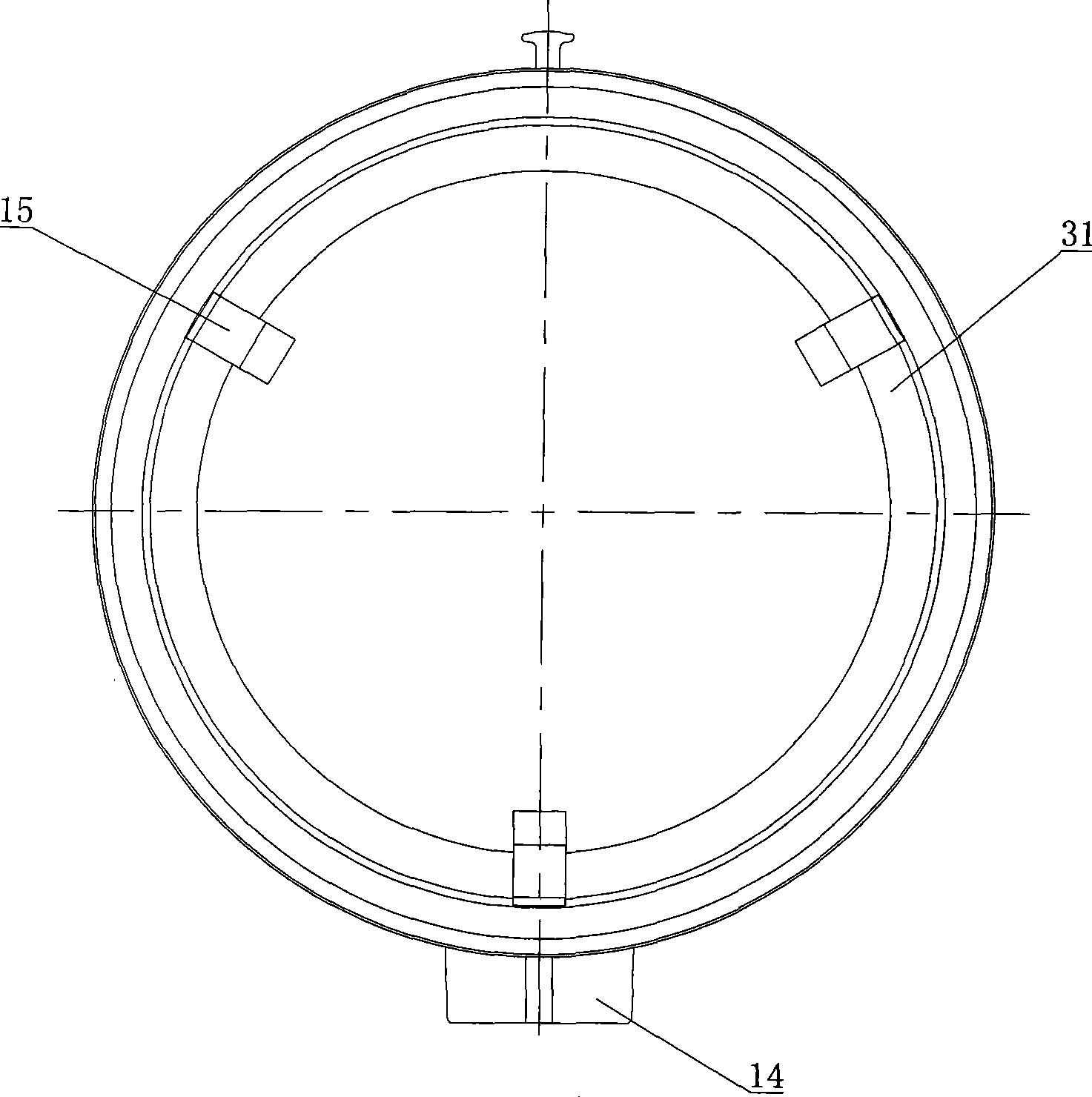

[0051] Such as figure 1 , figure 2 with image 3 As shown, the biomass semi-gasification furnace of the present invention includes a panel fire cover 1, an inner furnace 2, a secondary wind cover 3 and three positioning conjoined feet 15. The inner furnace 2 is composed of an inner shell 20, a thin-walled refractory furnace 9, a burner 4, an annular furnace bridge 5 and an insulating layer 10. The bottom of the inner shell 20 is provided with a back cover, and the three positioning connecting feet 15 are uniformly supported on the At the bottom of the inner shell 20, the inner side of the inner shell 20 is provided with an inwardly protruding annular rib. The annular furnace bridge 5 is supported on the annular rib. The thin-walled refractory furnace 9 is sleeved in the inner shell 20 and is located On the furnace bridge 5, the burner 4 is installed on the thin-walled refractory furnace 9, and a plurality of secondary air holes 40 are evenly arranged on the burner 4 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com