Concave-convex structure filter screen device of range hood

A concave-convex structure and range hood technology, which is applied in the range hood field, can solve the problems of small ventilation hole area of the filter screen device, affect the oil fume filtration, condensation, separation effect, affect the exhaust air volume of the range hood, etc., and achieve structural rigidity doubled , Efficiency improvement, and the effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

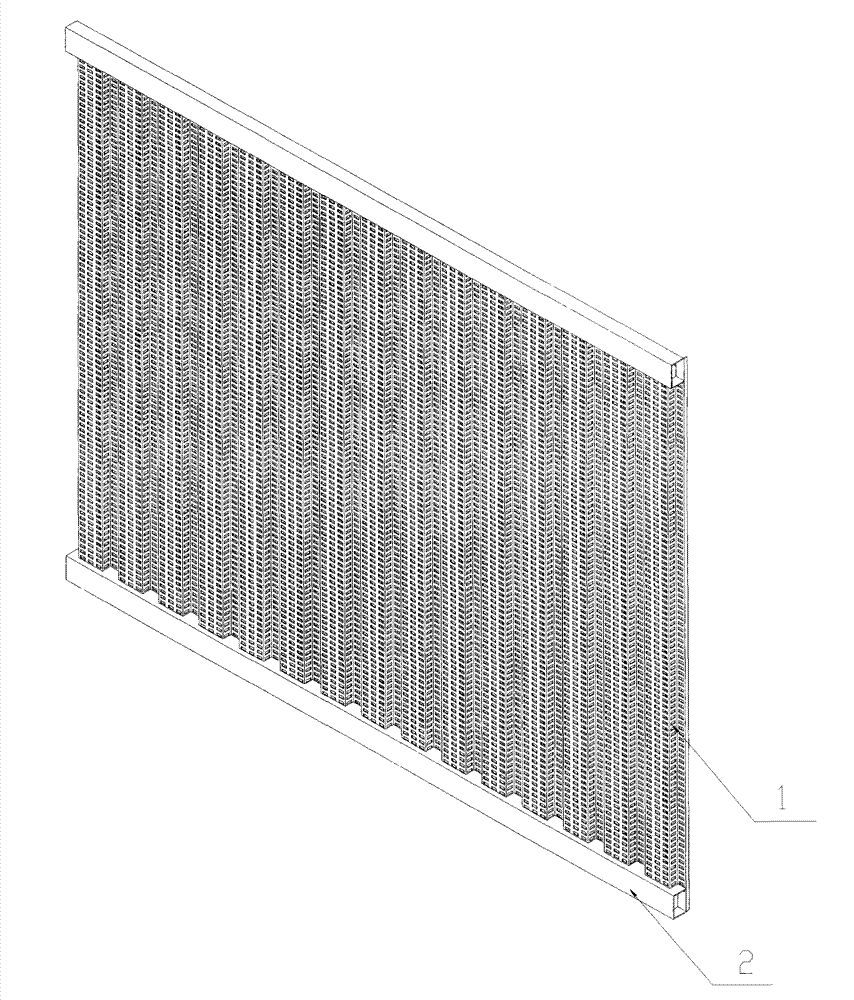

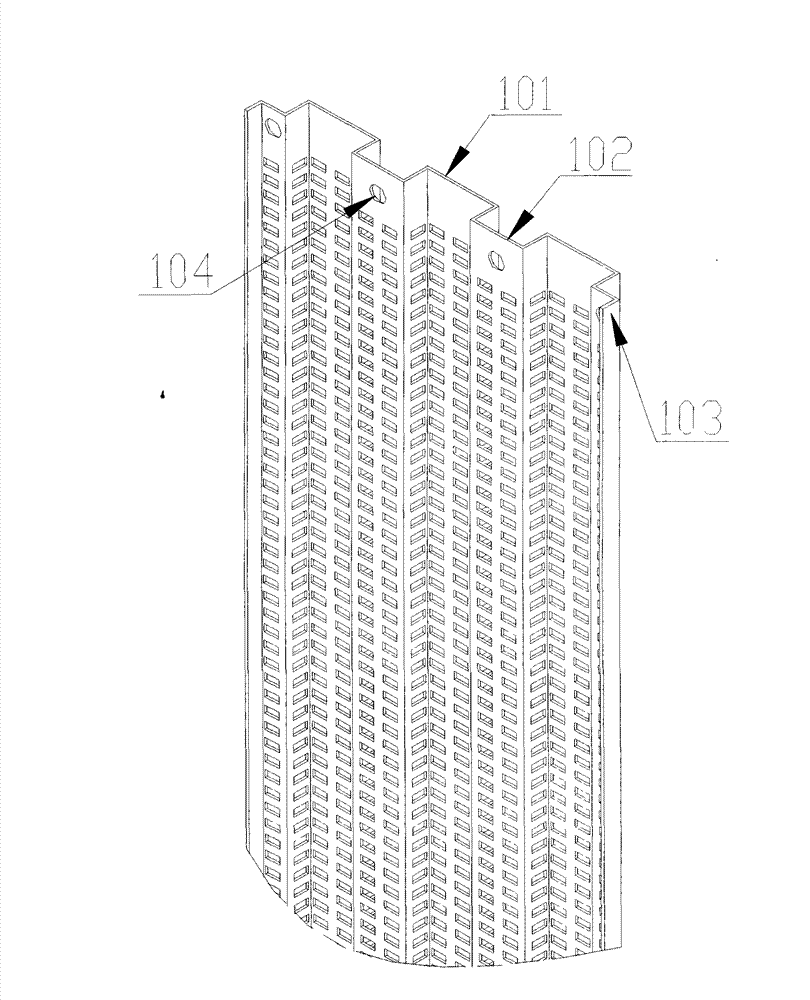

[0023] Such as Figure 1~3 As shown, the concave-convex structure filter device of the range hood includes at least a concave-convex structure filter 1 and a filter frame 2; the concave-convex structure filter is a metal perforated plate structure with strip-shaped holes on the surface; its concave-convex structure It is formed by connecting a plurality of strip-shaped convex sections 101 with the adjacent plane section 102. The section of the convex section is rectangular. Flanges 103 are respectively provided on the left and right sides of the filter screen. Mounting holes 104 are respectively provided on the plane section near the edge.

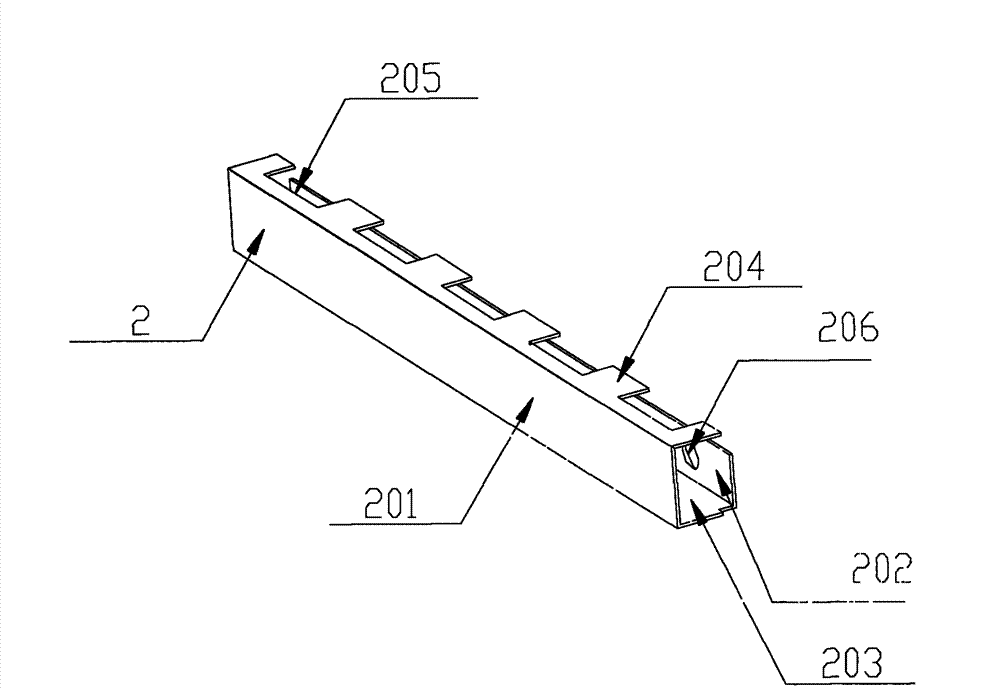

[0024] The filter frame 2 includes an upper frame and a lower frame. The cross section of the frame is groove-shaped. The frame is formed by connecting front and rear side plates 201, 202 and a bottom plate 203. A top plate 204 is also connected to the top of the front side plate. The rectangular groove 205 corresponding to the raised sectio...

Embodiment 2

[0027] There is no figure. The only difference from Embodiment 1 is that the cross section of the raised section of the filter screen is in the shape of an arc, and the top plate of the filter screen frame is provided with an arc-shaped groove corresponding to the raised section of the mesh wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com