Adsorbing fixed-type synchronous rotating auxiliary device for sewing round cut pieces

A technology of synchronous rotation and adsorption fixation, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of inability to guarantee the uniformity and beauty of products, difficulty in quality assurance, and low efficiency, so as to reduce the dependence on operator skills, Benefit improvement and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

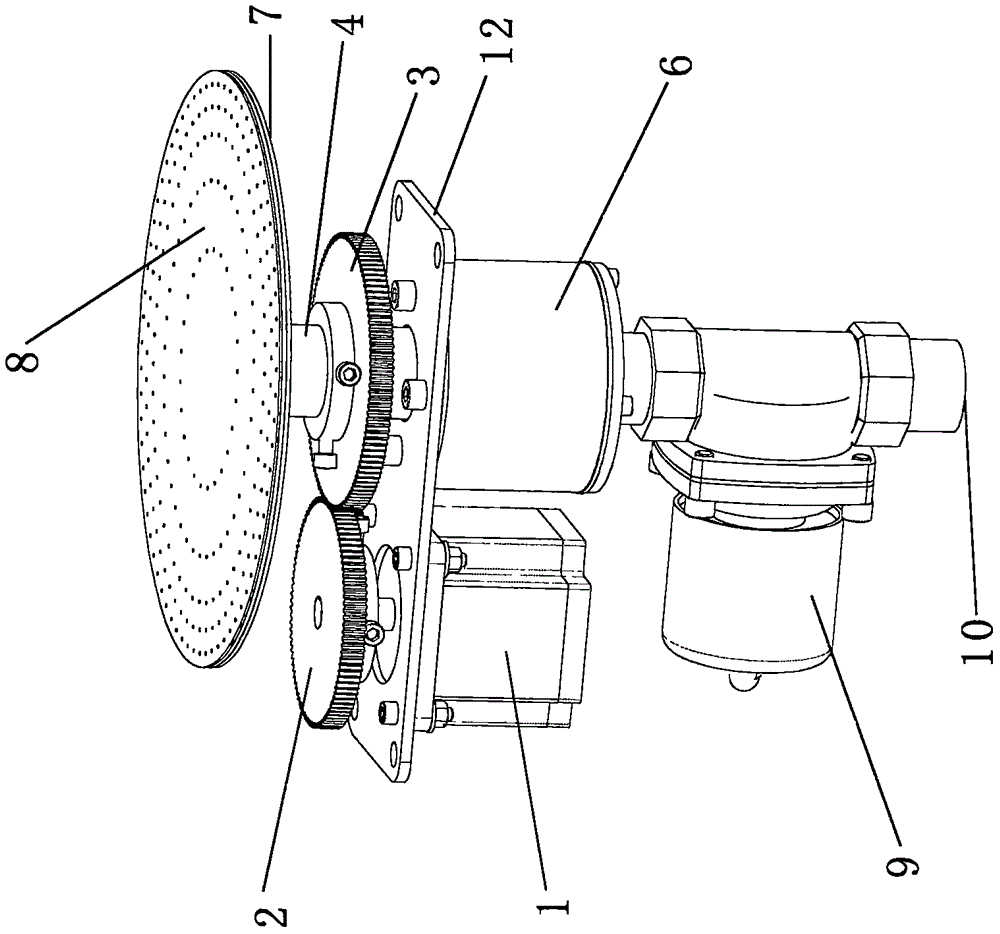

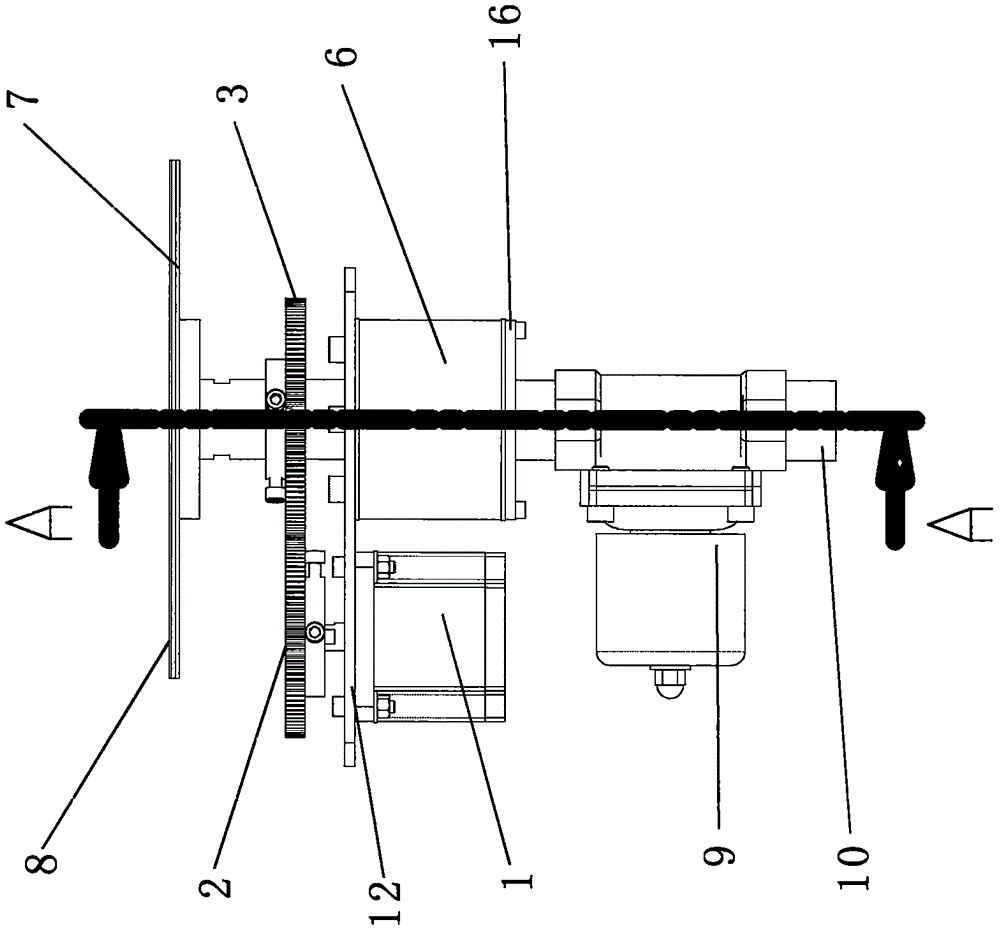

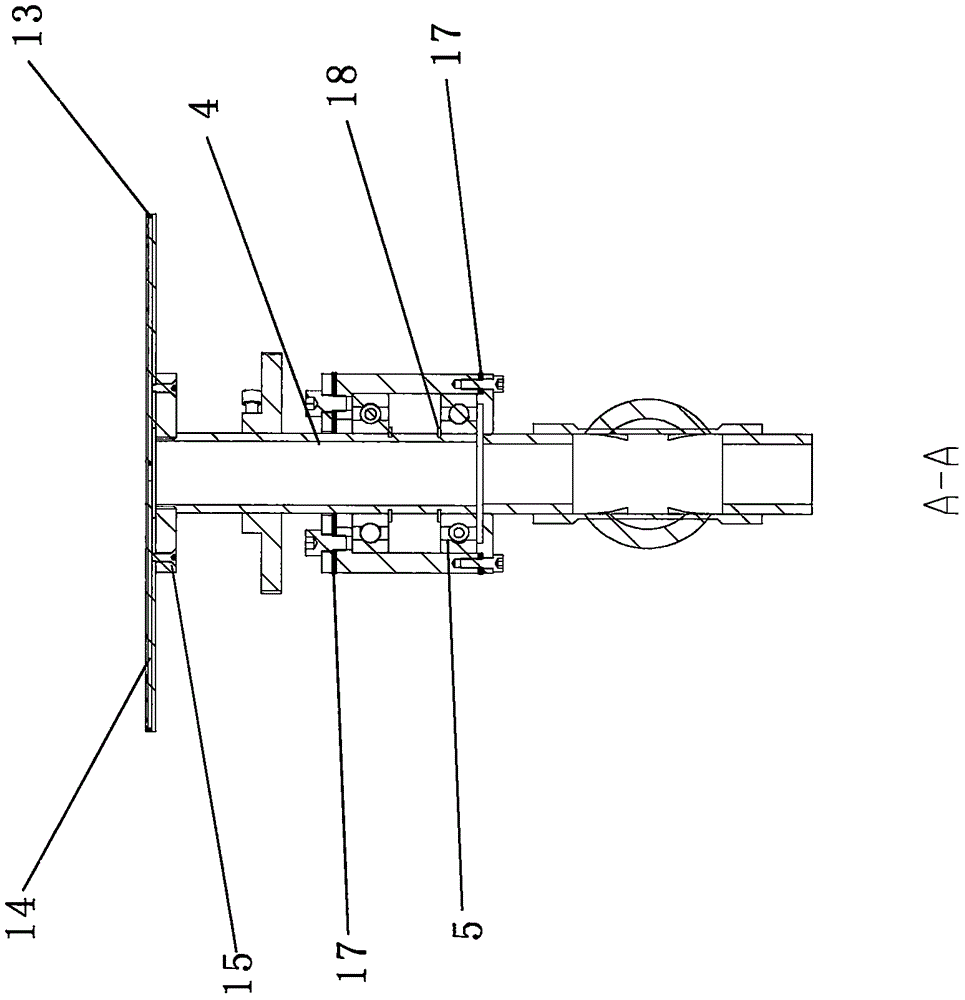

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0030] Such as Figure 1-3 As shown, the present invention provides a kind of adsorption fixed synchronous rotation circular cutting auxiliary device for sewing, including a control system, a transmission system and an adsorption system, and the control system is respectively connected with the transmission system, the adsorption system and the sewing machine through a PLC The drive system is connected; the control system includes: a control panel, a power supply connected to the control panel and the PLC control device, an encoder and a stepper motor driver connected to the PLC control device, wherein the The encoder is connected with the main shaft of the sewing machine so that the main shaft speed signal is input to the PLC control device; the transmission system includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com