Oil filter adopting full-frequency-band working-condition self-adaption smoothing, electrification and rotational magnetic field

A technology of adaptive filtering and rotating magnetic field, applied in servometer circuits, fluid pressure actuation devices, fluid pressure actuation system components, etc. To reduce the cost and complexity of filtering, suppress the increase in the thickness of the filter cake, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

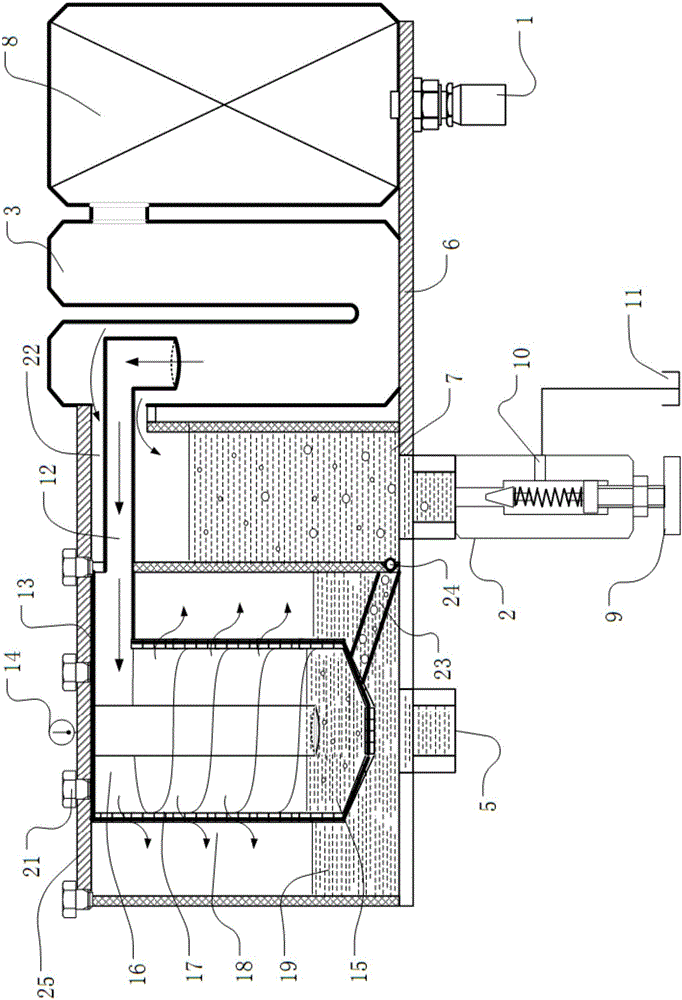

[0040] Please refer to the attached figure 1 To attach Figure 18 As shown, the present invention is an oil filter with adaptive filtering, electrification and rotating magnetic field in full frequency range, which consists of a base plate 6, a filter 8, a U-shaped particle separation module 3, an oil return cylinder 7, and an inner cylinder 15. The spiral flow channel 17, the filter element 18, the outer barrel 19 and the end cover 25 are composed of several parts. Wherein, the filter 8 , the U-shaped particulate separation module 2 , the oil return cylinder 7 , and the outer barrel 19 are placed on the bottom plate 6 in sequence.

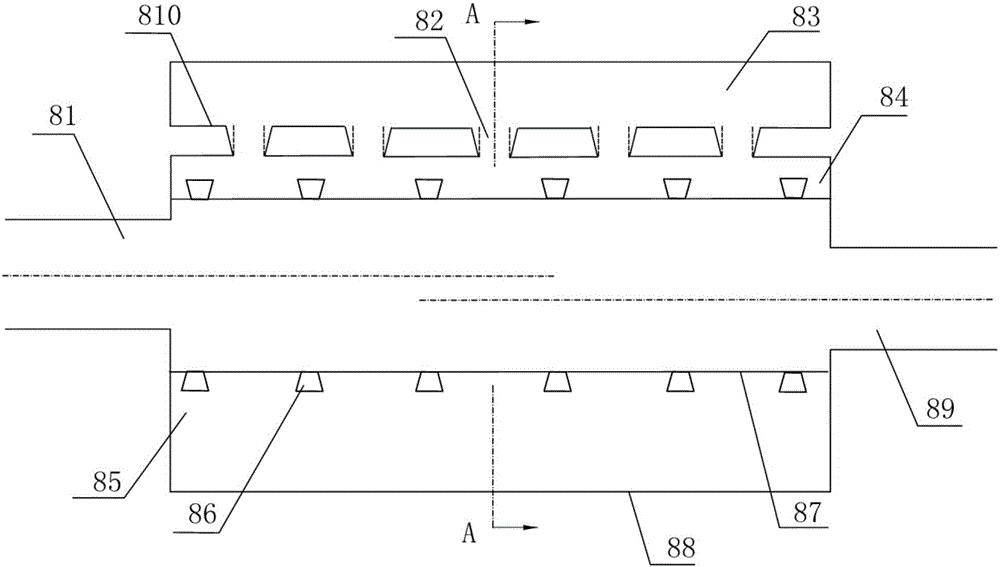

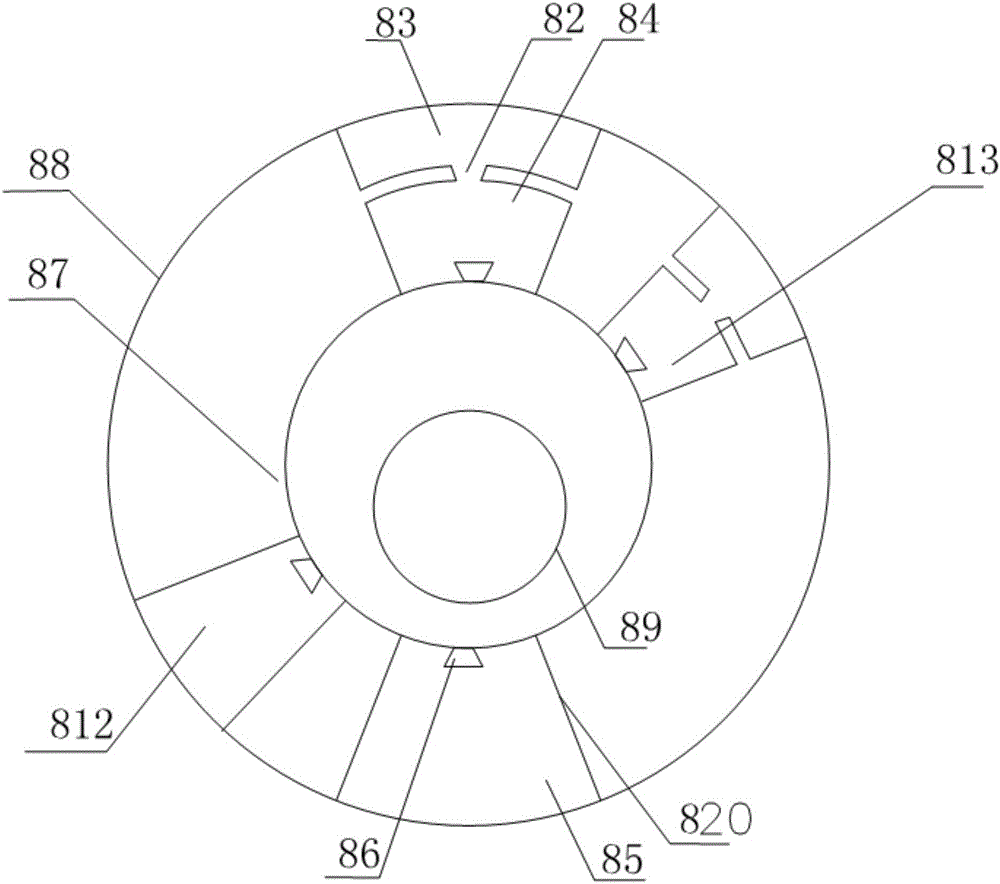

[0041] The filter 8 is used to input the hydraulic oil, and can attenuate the pulsating pressure in the high, medium and low frequency bands in the hydraulic system, and suppress the flow fluctuation. The filter 8 is composed of an input tube 81 , a casing 88 , an output tube 89 , an elastic thin wall 87 , an H-type filter 812 and a series H-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com