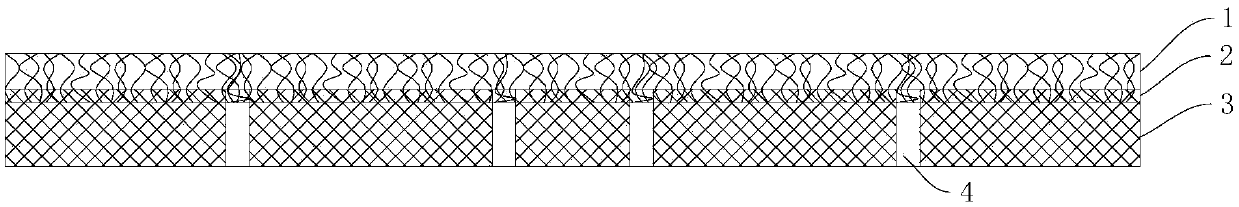

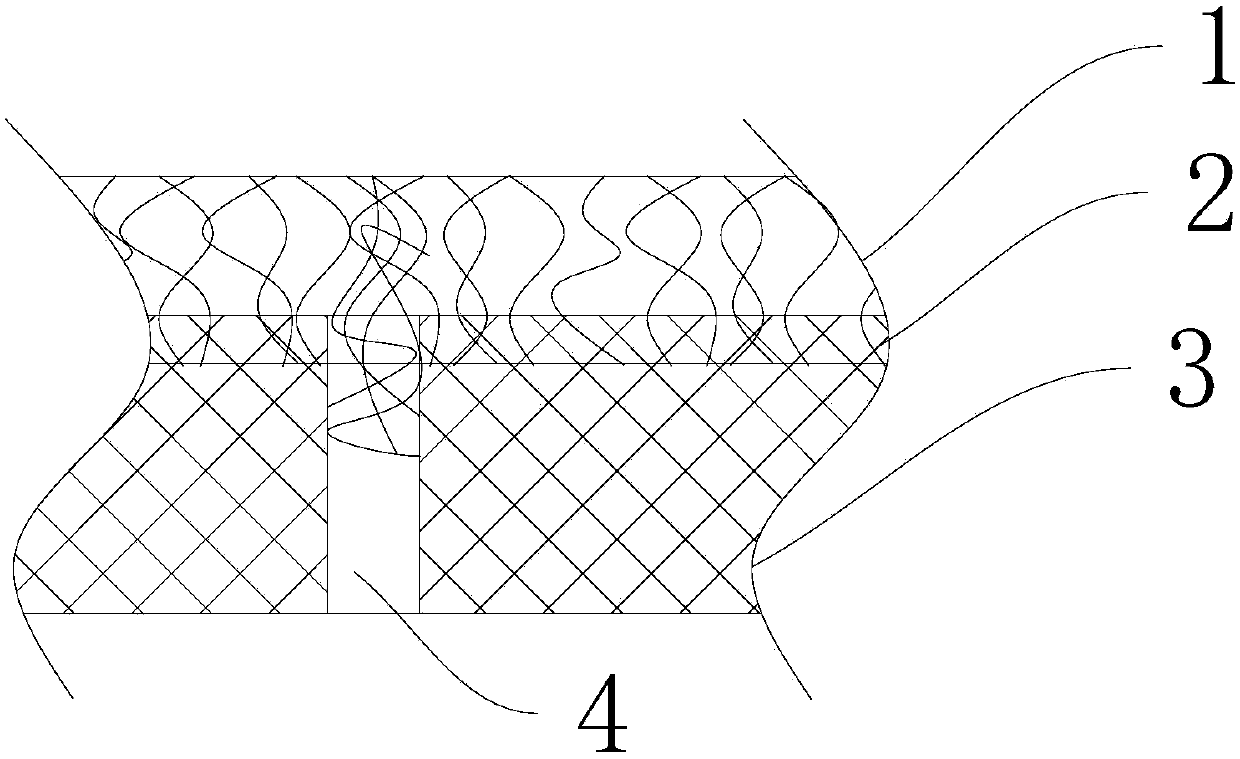

Composite non-woven fabric for filtering dust and manufacturing process thereof

A manufacturing process and technology of non-woven fabrics, applied in the field of composite non-woven fabrics and its manufacturing process, can solve the problems that the precision and air permeability of non-woven fabrics cannot be satisfied at the same time, achieve excellent dust filtration performance, guarantee service life, and improve filtration performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

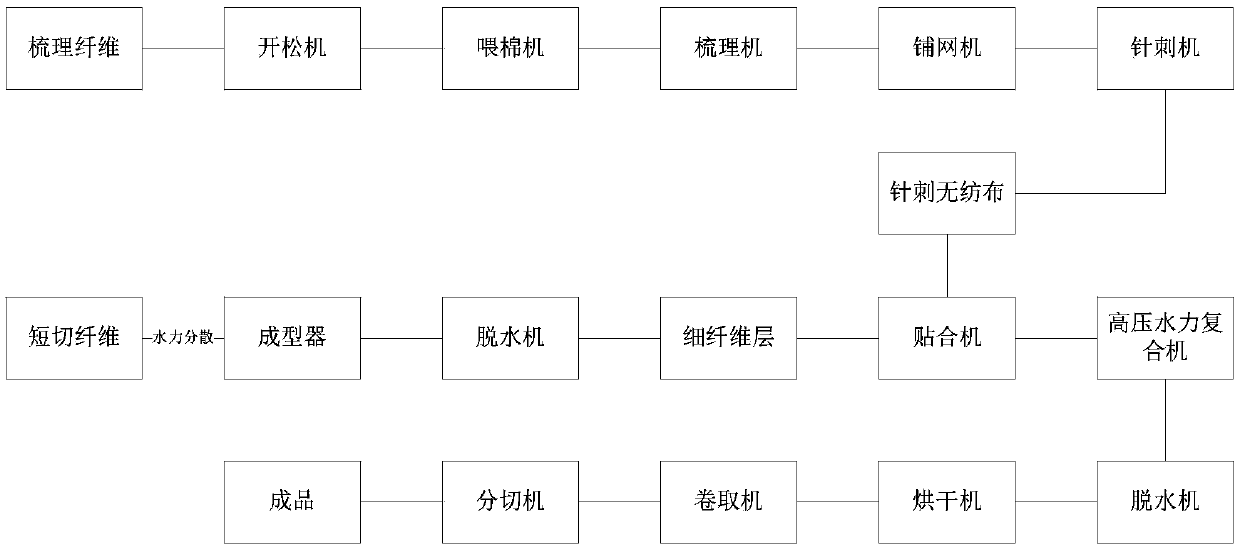

[0052] In the present embodiment, the composite non-woven fabric manufacturing process is as follows:

[0053] 1. The polyester fiber with a fineness of 1.7dtx and a length of 38mm enters the cotton feeding machine after being loosened and weighed. The cotton feeding machine is adjusted to 2500 grams per minute according to the required gram weight. The carding machine combs the fed fiber into Gram weight is 50g / m 2 Cotton net, then superimposed into 500g / m by net lapper 2 The cotton net layer with a width of 2.5 meters enters the needle punching machine, and after 8 passes of needle punching at a speed of 5m / min, it is made into a needle punched non-woven fabric and enters the laminating machine.

[0054] 2. Dilute the polyester fiber with a fineness of 0.3dtx and a length of 4mm with water to a mixed solution with a concentration of 3%, and send the mixed solution to the fourdrinier former with a metering pump, and the feeding amount is 150g / min, and the fourdrinier former ...

Embodiment 2

[0067] In the present embodiment, the composite non-woven fabric manufacturing process is as follows:

[0068] 1. The polyester fiber with a fineness of 2.2dtx and a length of 42mm is fed into the cotton feeding machine after being loosened and weighed. The cotton feeding machine is adjusted to 4500g per minute according to the weight of the product. The carding machine combs the fed fiber into a grammage of 30g / m 2 Cotton net, laid into 300g / m by net lapper 2 The cotton net layer with a width of 2.5 meters is sent to the needle loom. After 10 passes at a speed of 10M / min, it is made into a needle-punched non-woven fabric and then enters the laminating machine.

[0069] 2. After the aramid fibers with a fineness of 1.0dtx and a length of 3mm are dispersed by water, they are made into a mixed solution with a concentration of 2%, and the mixed solution is sent to the inclined wire former with a metering pump at a concentration of 3%. The feed rate is 400g / min, the speed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com