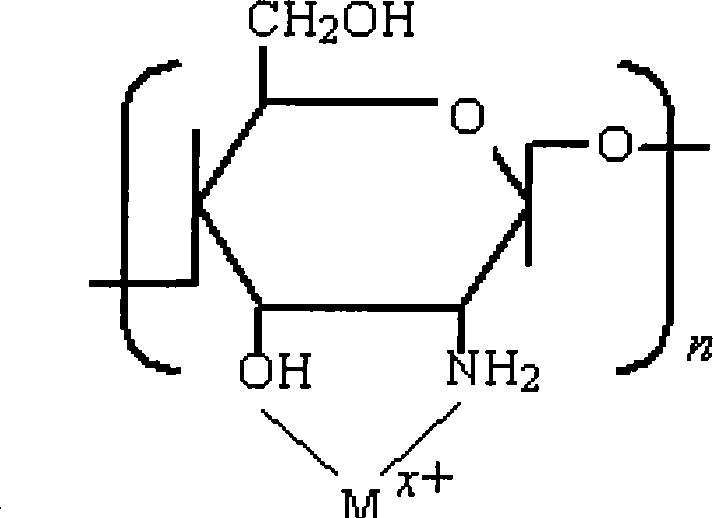

Application of chitosan complex for cigarette filter tip and preparation thereof

A cigarette filter and chitosan technology, which is applied in applications, e-liquid filter elements, tobacco, etc., to achieve the effect of improving filtration performance, simple use method, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1mol of powder chitosan (molecular weight is 10000, deacetylation degree is 90%) solution water, is mixed with the aqueous solution of 30wt%; Get the copper chloride of 0.143mol, dissolves in water, is mixed with the aqueous solution of 20wt% concentration; Add the copper solution into the chitosan solution under certain conditions, continue stirring for 30 minutes to obtain a uniform solution, and obtain a chitosan copper complex solution after standing for 8 hours. The chitosan complex is added to the cellulose acetate in an amount of 0.6% by weight of the cellulose acetate.

Embodiment 2

[0038] 1mol of powdered chitosan (molecular weight is 10000, deacetylation degree is 90%) solution water, is mixed with the aqueous solution of 30wt%; Get the ferric chloride of 0.143mol, dissolves in water, is mixed with the aqueous solution of 20wt% concentration; All the other operations Same as implementation 1.

Embodiment 3

[0040] 1mol of powder chitosan (molecular weight is 10000, deacetylation degree is 90%) solution water, is mixed with the aqueous solution of 30wt%; Get the ferric chloride of 0.071mol and the cupric chloride of 0.071mol, dissolve in water altogether, be mixed with An aqueous solution with a concentration of 20 wt %; the mixed solution of iron and copper is added to the chitosan solution under stirring conditions, and the stirring is continued for 30 minutes to obtain a uniform solution; the rest of the operations are the same as in Implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com