Preparation method of superfine fiber melt-blown cloth

A technology of ultra-fine fiber and melt-blown cloth, which is applied in the directions of melt spinning, fiber processing, non-woven fabrics, etc., can solve the problems of high fiber difficulty, difficulty in filtration efficiency reaching 99.99%, and the filtration effect cannot meet the demand, etc. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

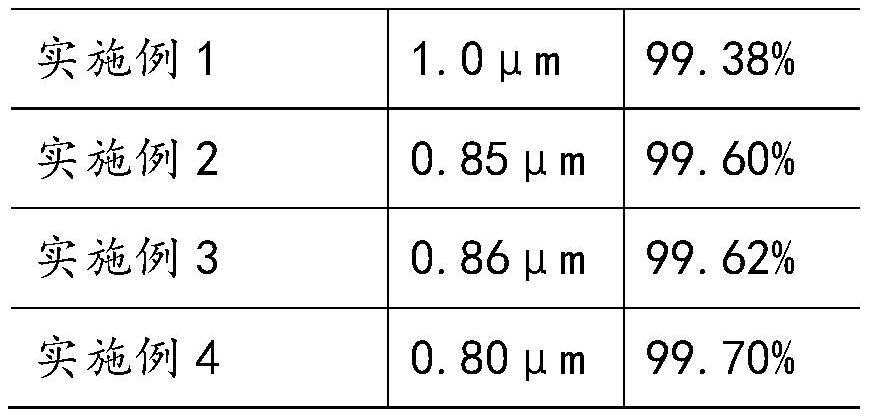

Examples

preparation example Construction

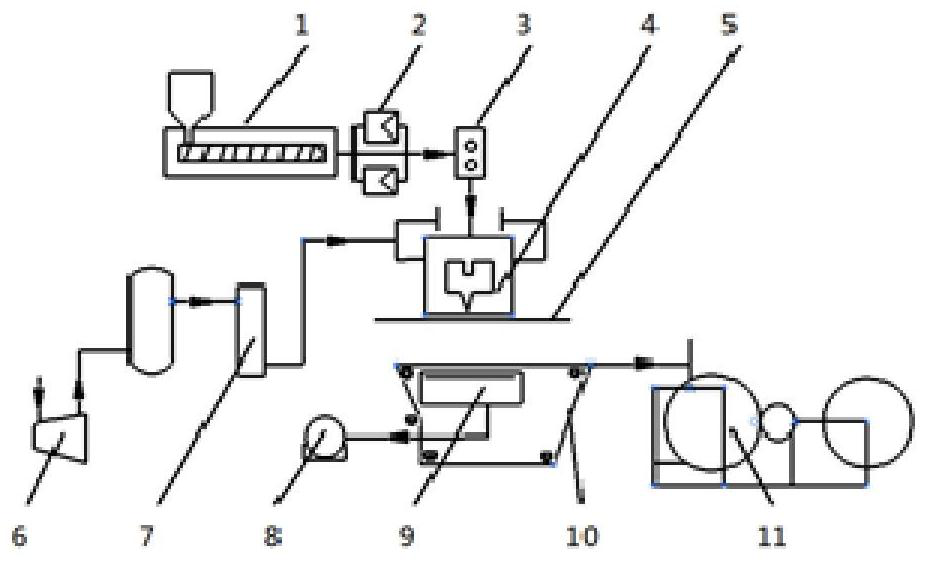

[0022] figure 1 It is a flow chart of a common preparation device for melt-blown non-woven fabrics. As shown in the figure, it includes a screw extruder 1, a melt filter 2, a gear metering pump 3, a melt-blown die head assembly and a receiving device. The general process is First place the raw material slices in the hopper of the screw extruder, and after melting, the melt is transported to the melt filter, and then the filtered melt is transported to the gear metering pump, and the metering is transported to the melt-blown die head assembly. 4 The air holes on both sides of the spinneret hole are pressurized to eject the melt, and the air holes on both sides of the spinneret hole of the melt nozzle 11 are pressurized and filled with air by the external air compressor 6 and the air heater 7, The receiving device receives and forms the non-woven fabric, and the receiving device can choose a condensing net curtain or a roller, preferably using a mesh belt receiver 10 and a suppo...

Embodiment 1

[0028] A preparation method of superfine fiber melt-blown cloth, comprising the following steps:

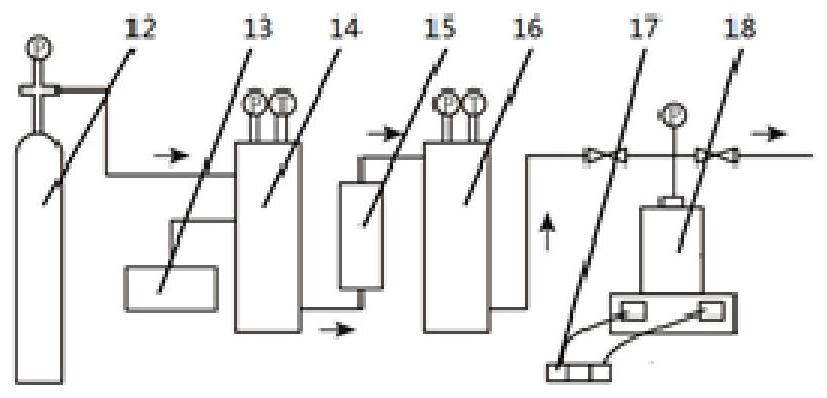

[0029] 1) Supercritical infiltration: such as figure 2 As shown, the particles made of PP material commonly used in the melt blown process are placed in the high-pressure reactor body, and the carbon dioxide enters the preheating storage tank through the booster pump from the gas storage tank through the condensation conveying device, is heated into gas, and then pressurized into the In the kettle body, the temperature in the kettle body is raised, and the pressure is increased to 13Mpa, and the temperature is about 52°C, so that the carbon dioxide is in a supercritical state and maintained for 3 hours. After that, the gas in the kettle body is quickly emptied, and the PP particles are placed in the air for 3 hours, and the treatment is completed. .

[0030] 2) Place the treated PP particles in figure 1 In the hopper of the screw extruder shown in , set the temperature of each...

Embodiment 2

[0033] A preparation method of superfine fiber melt-blown cloth, comprising the following steps:

[0034] 1) Supercritical infiltration: such as figure 1 As shown, the particles prepared by PET material polyester commonly used in the melt blown process are placed in the high-pressure reactor body, and the carbon dioxide enters the preheating storage tank through the booster pump from the gas storage tank through the condensation conveying device, and is heated into gas, and then added The pressure enters the kettle body, and the temperature in the kettle body is raised, and the pressure is increased to 14Mpa, and the temperature is about 35°C, so that the carbon dioxide is in a supercritical state and maintained for 4 hours. Finished.

[0035] 2) Place the treated PET particles in figure 1In the hopper of the screw extruder shown in , set the temperature of each zone of the extruder, the temperature of zone 1 is 170°C, the temperature of zone 2 is 210°C, the temperature of z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com