Multi-layer filtration gas-liquid separation device for low-pressure gas well

A gas-liquid separation device and multi-layer filtration technology, which are applied in combination devices, separation methods, dispersed particle filtration, etc., can solve the problems of blockage of the drain pipe, high production cost, complex structure of the gas-liquid separator, etc., and improve the filtration efficiency. The effect of performance, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

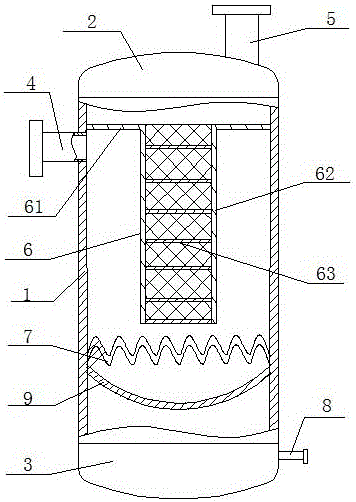

[0020] Multi-layer filter gas-liquid separation device for low-pressure gas well, such as figure 1 As shown, including a cylinder 1, the upper end of the cylinder 1 is provided with an upper end cover 2, the lower end of the cylinder 1 is provided with a lower end cover 3, the cylinder wall near the upper end of the cylinder 1 is provided with an air inlet pipe 4, and the upper end cover 2 is provided with There is an air outlet pipe 5, a liquid discharge pipe 8 is arranged on the side wall of the lower end cover 3, and a filter element 6 with a T-shaped cross section is arranged inside the cylinder body 1, and the filter element 6 includes a connecting part 61 arranged horizontally, a filter cartridge 62 arranged vertically and There are several filter discs 63 arranged in the filter cartridge 62. There are 7 filter discs 63 in this embodiment. Of course, other numbers of filter discs 63 can be designed according to actual needs. On the upper end surface, the bottom of the fi...

Embodiment 2

[0024] This embodiment is a further improvement on the above-mentioned embodiment, as figure 1 As shown, in the present embodiment, the filter aperture of the corrugated filter screen 7 is greater than the filter aperture of the collection filter screen 9, so that the solid impurities on the corrugated filter screen 7 can smoothly fall to the collection filter screen 9, avoiding the corrugated filter screen. Too many impurities on the net 7 will affect the gas flow at the bottom of the cylinder body 1 and reduce the bearing capacity on the corrugated filter net 7 to prevent it from being damaged. Both the collection filter screen 9 and the corrugated filter screen 7 are detachably connected to the inner wall of the cylinder body 1, which is convenient for cleaning the cylinder body 1 regularly.

Embodiment 3

[0026] This embodiment is a further improvement on the above-mentioned embodiment, as figure 1 As shown, in this embodiment, the upper end cap 2 and the lower end cap 3 are threadedly connected with the cylinder body 1, the connection between the upper end cap 2 and the lower end cap 3 and the cylinder body 1 is coated with sealant, and the air inlet pipe 4 is tightly connected with the cylinder body 1 , The air outlet pipe 5 is in sealing connection with the upper end cover 2, and the liquid discharge pipe 8 is in sealing connection with the lower end cover 3. The upper end cover 2 and the lower end cover 3 are threadedly connected, which is convenient for the maintenance of the present invention, and the above-mentioned connection nodes are sealed to ensure the airtightness of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com