Filtration device

A filter device and filter tank technology, which is applied in the direction of filter circuit, filter separation, membrane filter, etc., can solve the problems of deformation of the mesh drum, and achieve the effect of simple structure, waste suppression, compactness and filter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

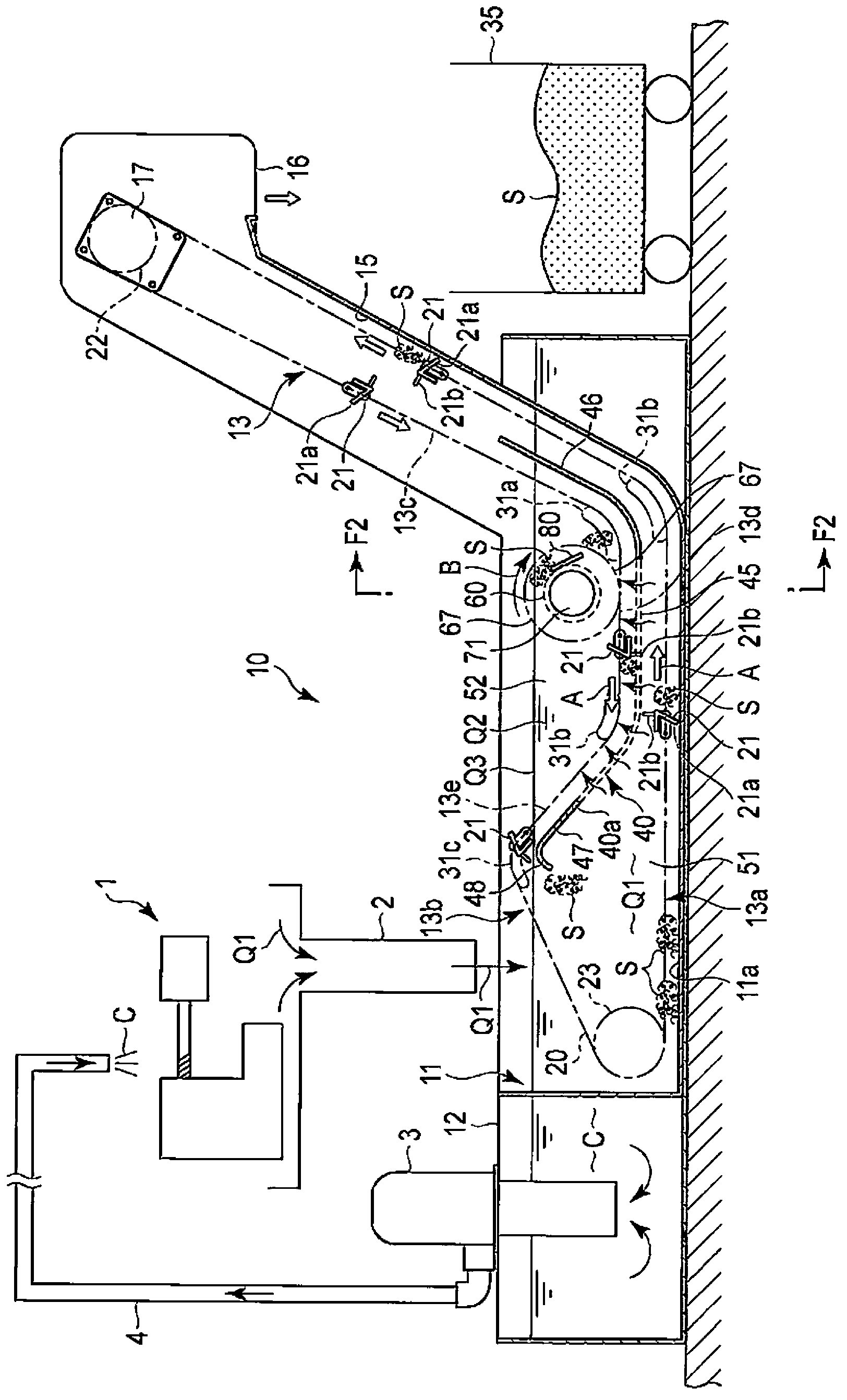

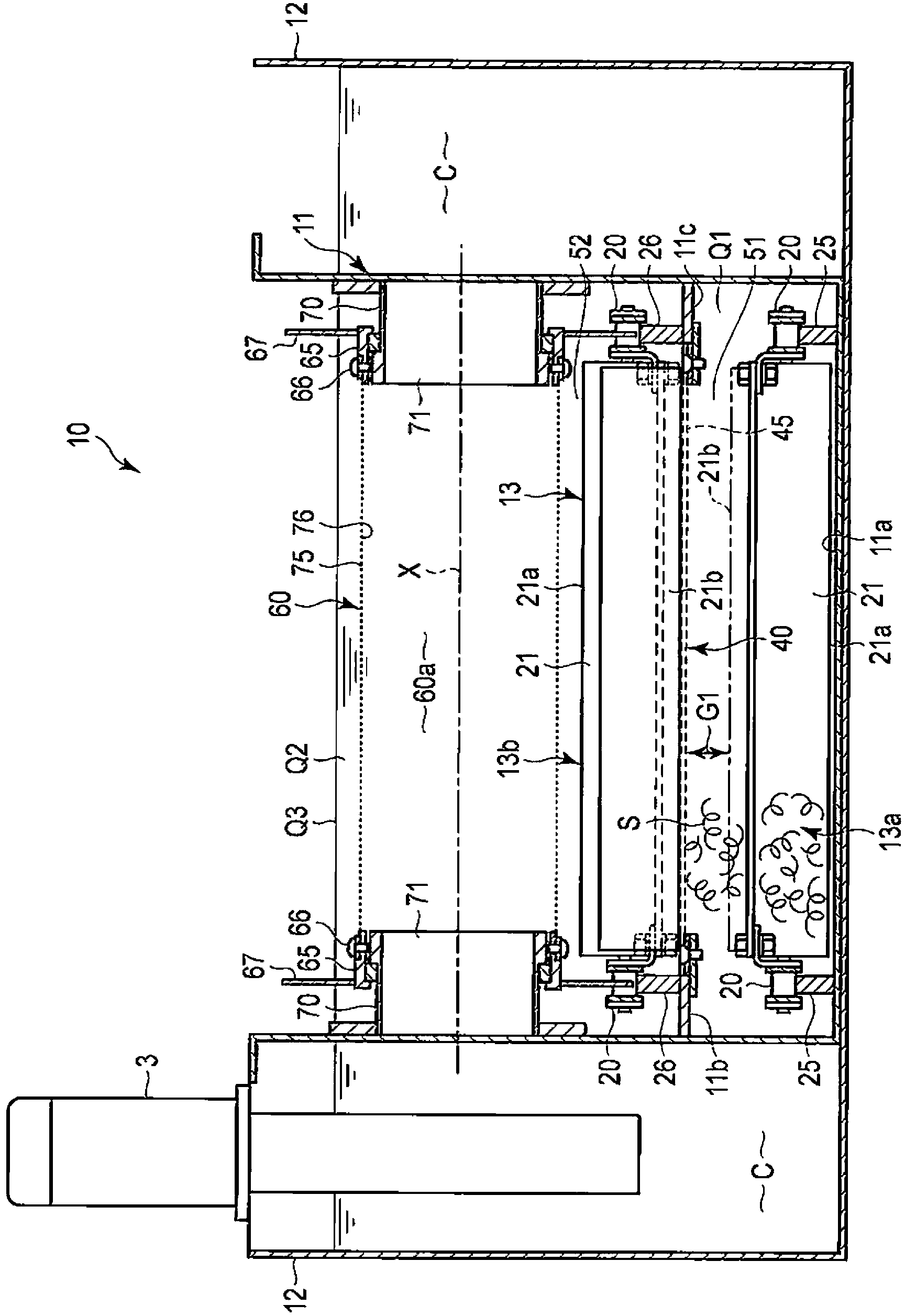

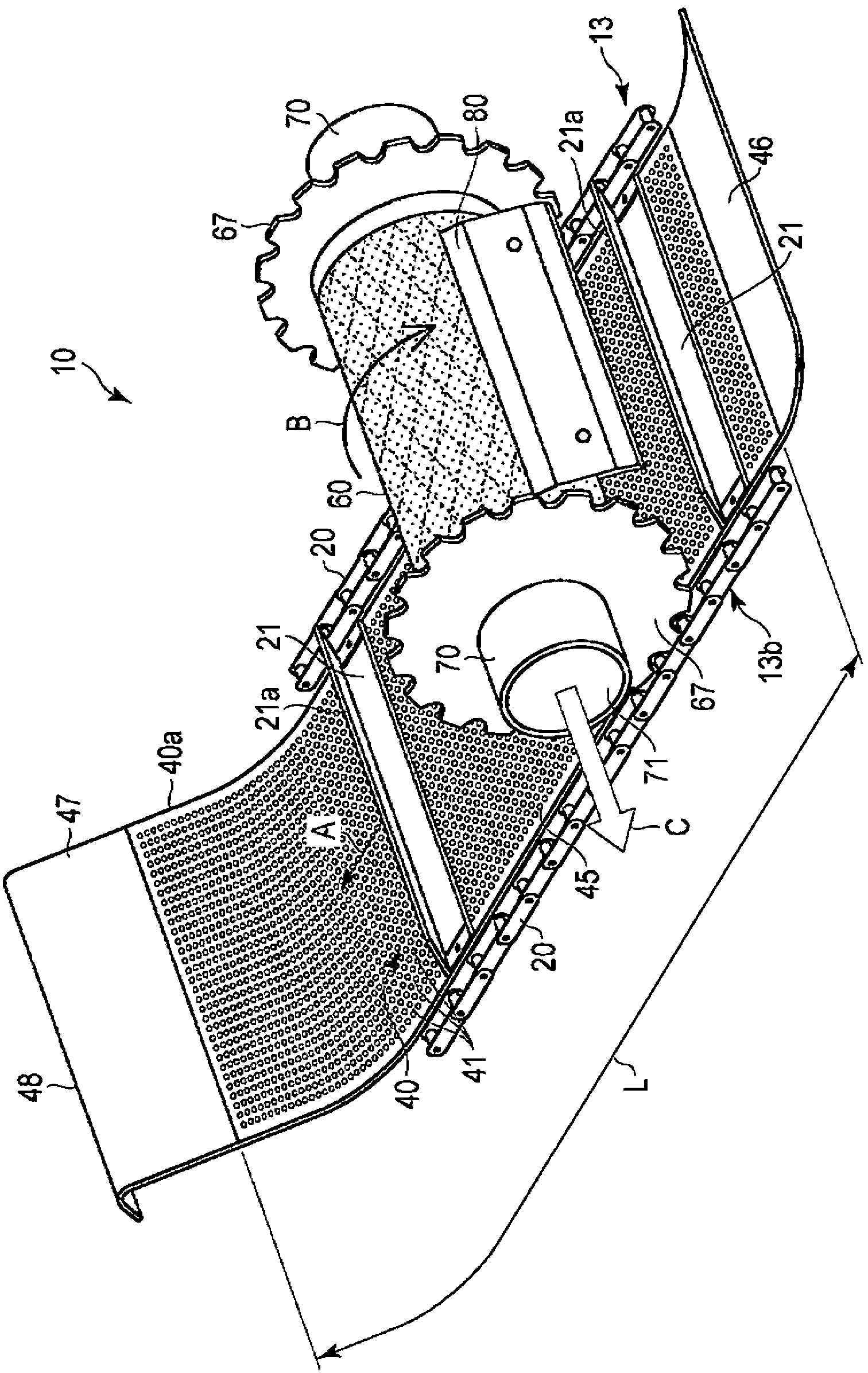

[0025] Refer to the following Figure 1 to Figure 7 A filter device according to one embodiment of the present invention will be described.

[0026] figure 1 A schematic configuration of a facility for removing foreign matter from a coolant (cutting fluid) used in a machine tool 1 such as a machining center is shown. The coolant discharged from the machine tool 1 is an example of the fluid Q1 to be filtered. In the treatment liquid Q1 , depending on the raw material to be processed, for example, scraps of aluminum alloys, magnesium alloys, iron-based metals, etc., non-metallic particles such as carbon, etc. generated by cutting etc. are mixed.

[0027] The processing liquid Q1 containing chips, fine particles, etc. flows from the machine tool 1 through the flow path 2 and is supplied to the filter device 10 . The treatment liquid Q1 is filtered once by the filter device 10 and becomes the treatment liquid Q2. Furthermore, the treatment liquid Q2 becomes the cleaning liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com