Concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and common reinforcement for connection

A technology of concrete-filled steel tube columns and ordinary steel bars, which is applied in the direction of construction and building construction, to achieve the effects of small prestress loss, increased shear bearing capacity, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

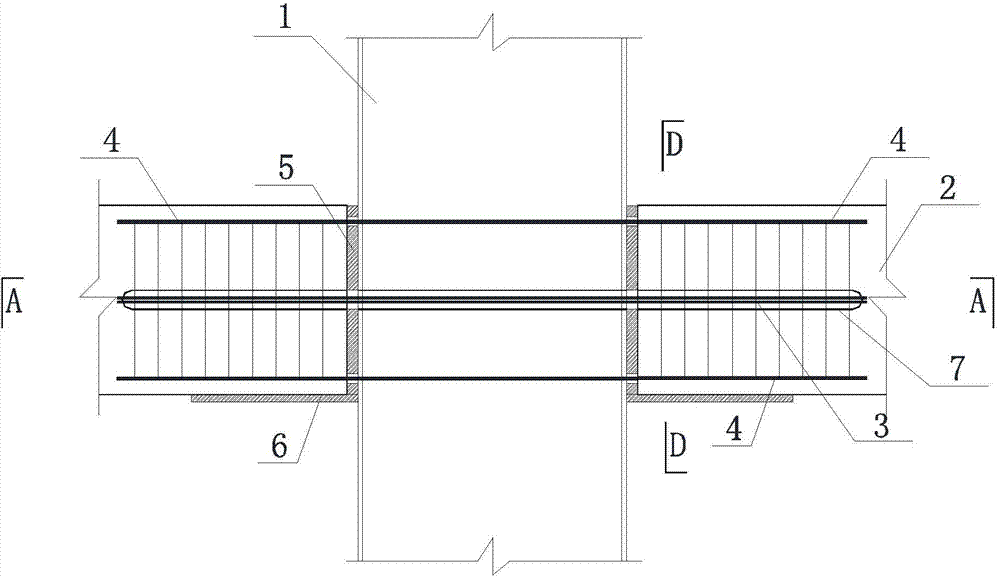

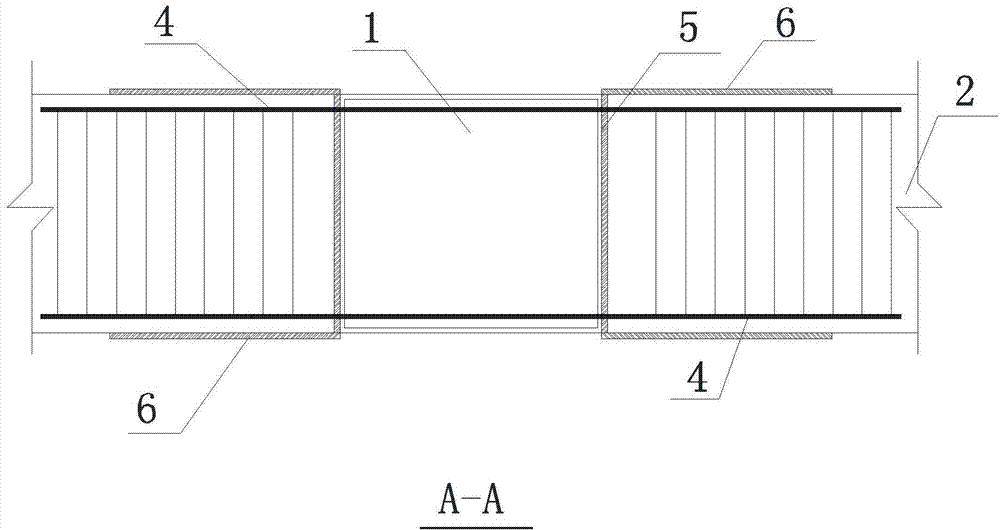

[0023] The composite joint structure of square and rectangular concrete-filled steel tube columns of concrete beams connected by unbonded prestress and ordinary steel bars is as follows: figure 1 Shown:

[0024] 1. Positioning of square and rectangular concrete filled steel pipes

[0025] The steel pipes of the square and rectangular concrete-filled steel pipe columns (1) are drilled in strict accordance with the drawings in the steel structure processing plant; the steel plates (5) and channel steel ( 6); hoisting and positioning of square and rectangular concrete filled steel tube columns (1).

[0026] 2. Binding beam reinforcement skeleton and prestressed reinforcement

[0027] Support the beam bottom formwork, bind the beam steel skeleton strictly according to the design drawings; support one side of the side formwork, draw the metal bellows positioning line on the side formwork according to the position of the prestressed tendons given in the drawing, and weld them on t...

Embodiment 2

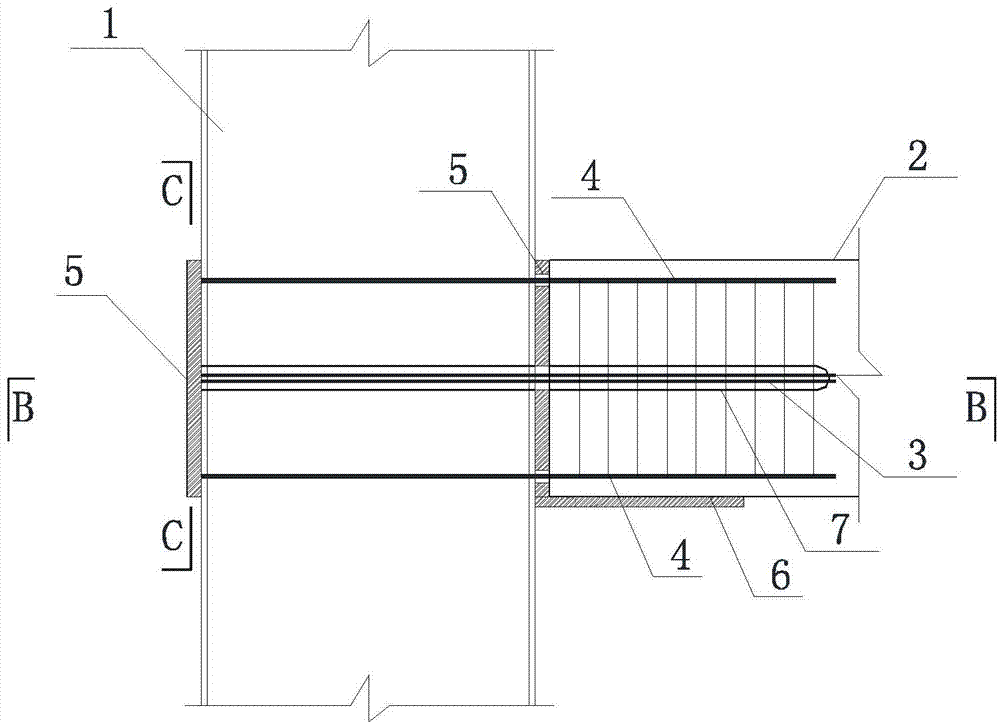

[0037] See when it is a side column node figure 2 , other measures are the same as embodiment 1, except that at the end of the side column, the unbonded prestressed tendon is welded on the steel plate (5), and this ring plate can be used as a pressure bearing plate when the unbonded prestressed tendon is stretched.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com