Patents

Literature

30results about How to "Small shock resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection

ActiveCN103924680AGuaranteed reliabilityReduce weakening effectBuilding constructionsSheet steelReinforced concrete

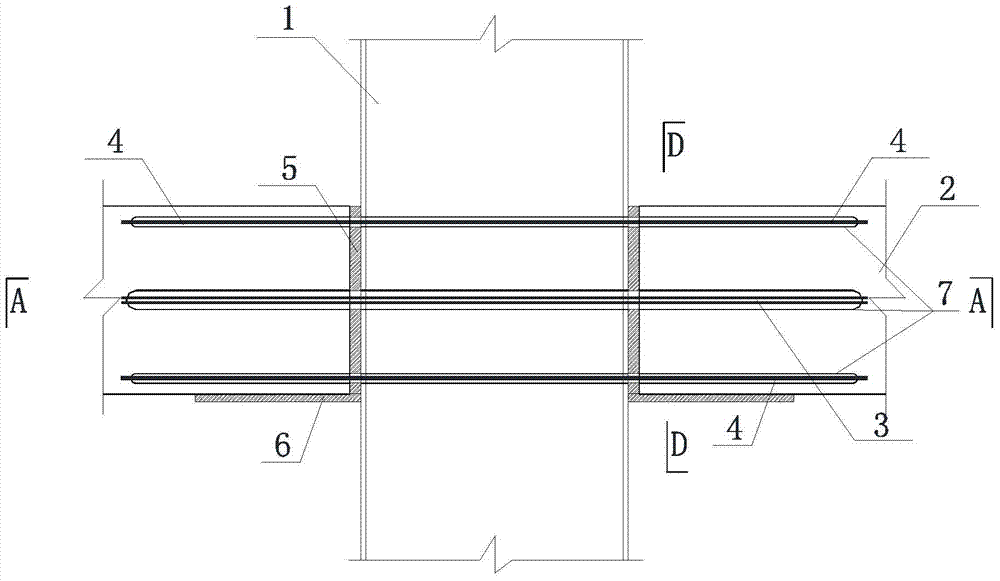

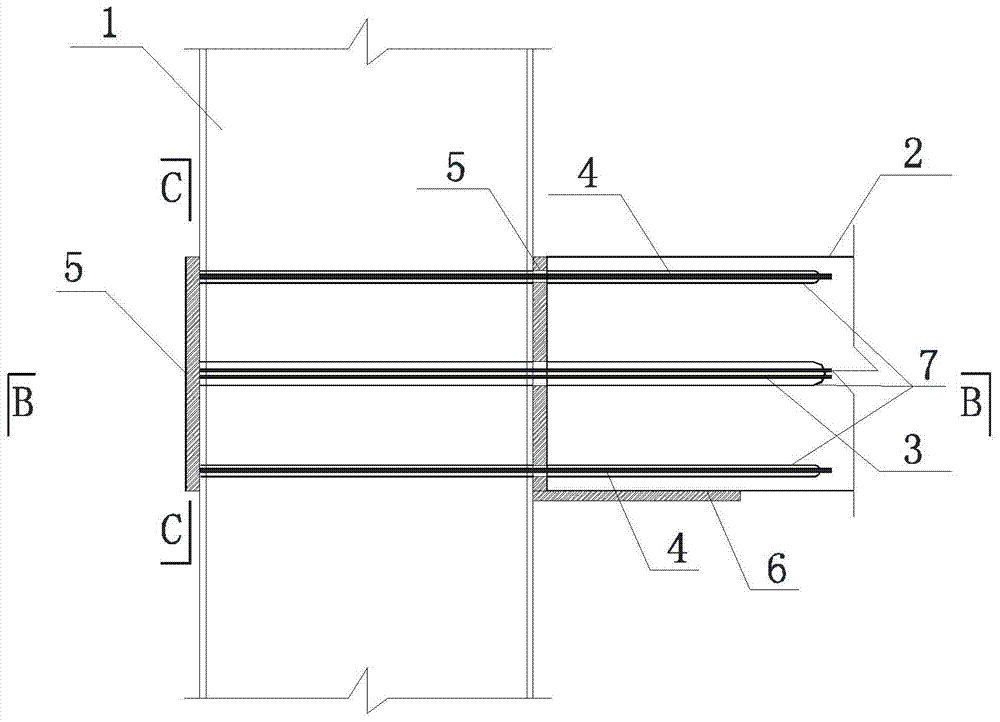

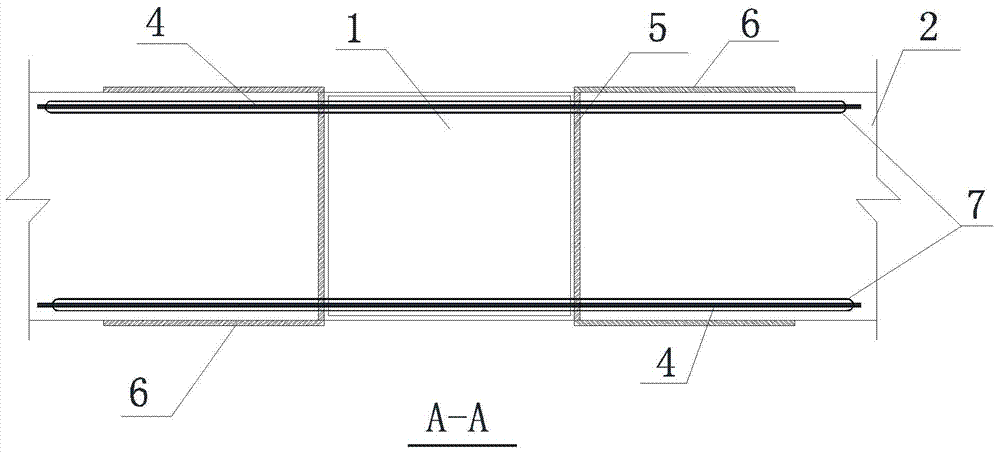

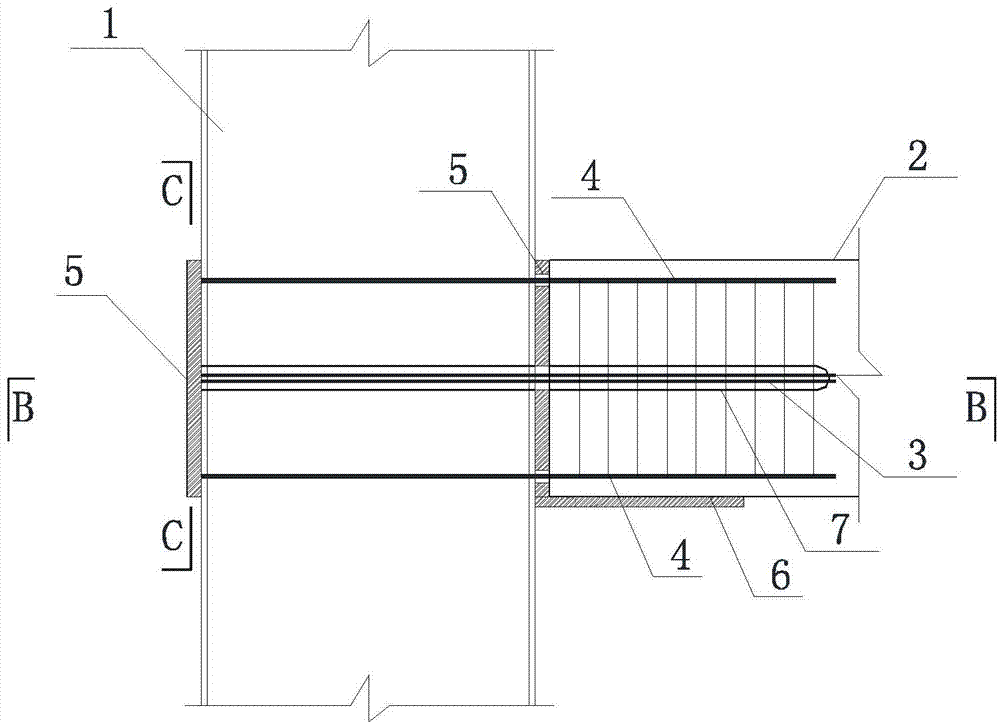

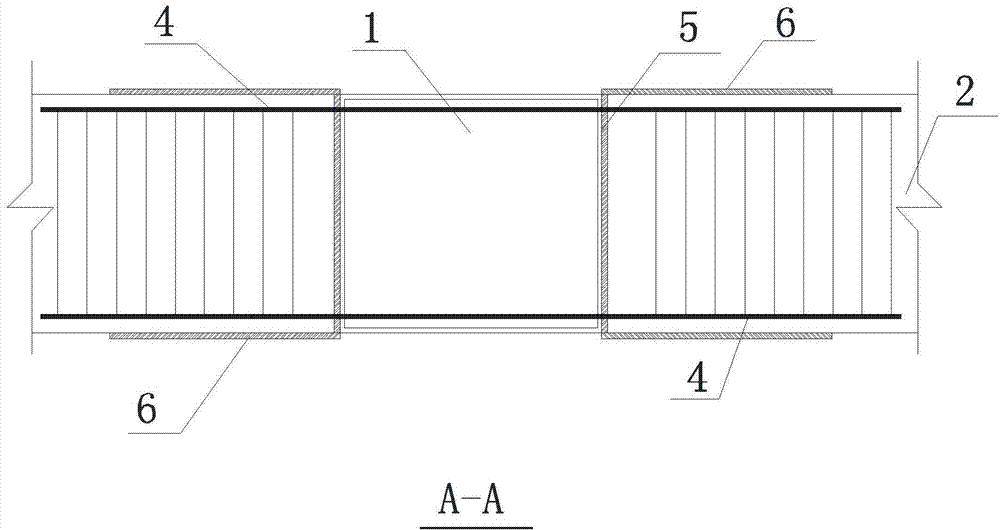

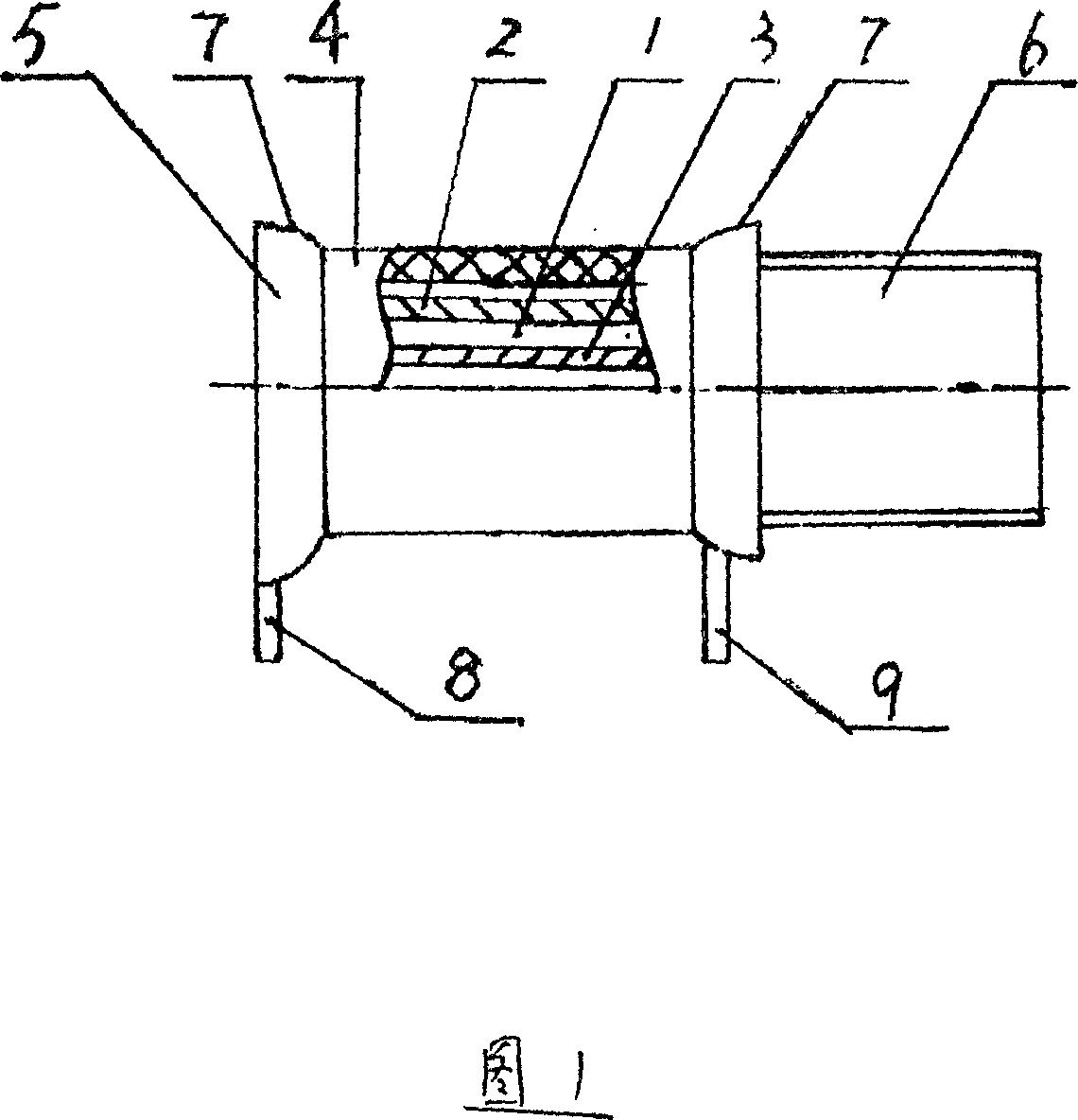

The invention relates to a precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection and belongs to the technical field of building structures. The precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are precast. The parts, corresponding to the beam section, of the square-rectangular concrete-filled steel tube column and the precast reinforced concrete beam are provided with ducts in which metal bellows are embedded. The steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam. The steel channels are welded on the square-rectangular concrete-filled steel tube column. Ordinary rebars and unbonded prestressed rebars are passed through the metal bellows, and the prestressed rebars are tensioned so that the beam and the column are integrated. The precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability is guaranteed, seismic performance is good, and the joint has promising application prospect.

Owner:宝嘉智能科技(南通)有限公司

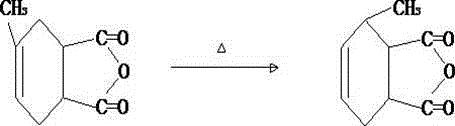

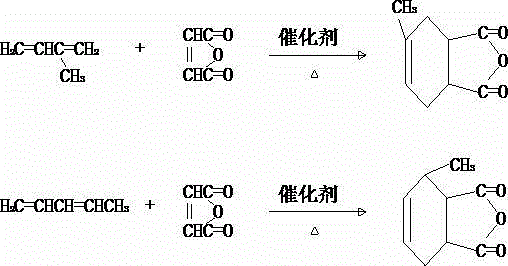

Method for producing liquid methyl tetrahydrophthalic anhydride

The invention relates to the technical field of methyl tetrahydrophthalic anhydride, and in particular relates to a method for producing liquid methyl tetrahydrophthalic anhydride. According to the invention, pentadiene, isoprene and maleic anhydride are used as major raw materials, and the method is adopted, so that the liquid methyl tetrahydrophthalic anhydride has the advantages of low solidification point, good operability, shallow color and luster, low volatility, low toxicity and the like; and simultaneously, the condensate of the liquid methyl tetrahydrophthalic anhydride solidified with epoxy resin has the advantages of good insulativity, high pressure resistance, corrosion resistance, impact resistance, fission resistance, low shrinking deformation and the like, and is widely applied to industries such as electronic embedment and envelopment, electrical pouring, electric appliance dipping, insulating composite material winding and pultrusion.

Owner:南通市福来特化工有限公司

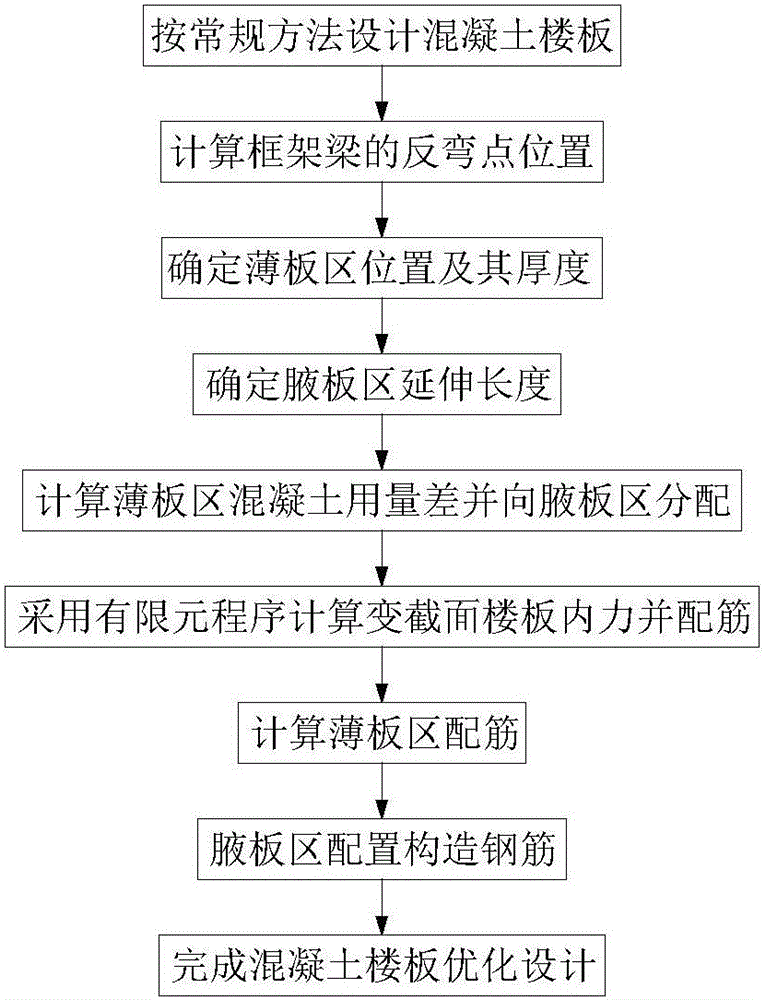

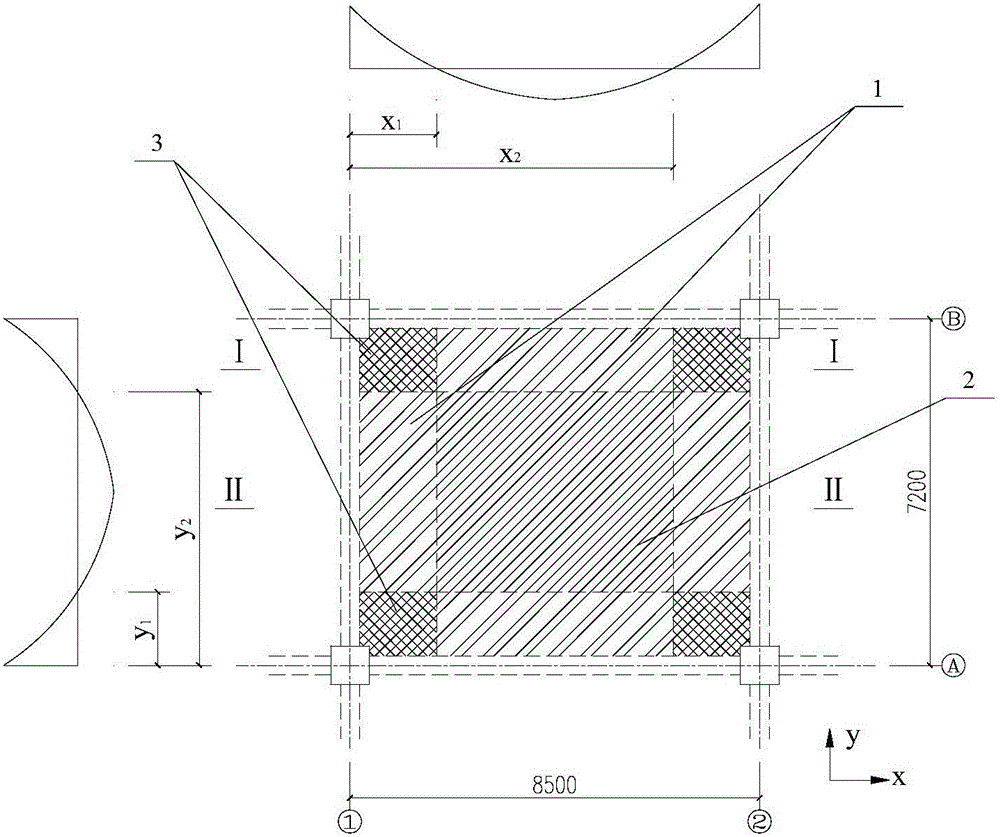

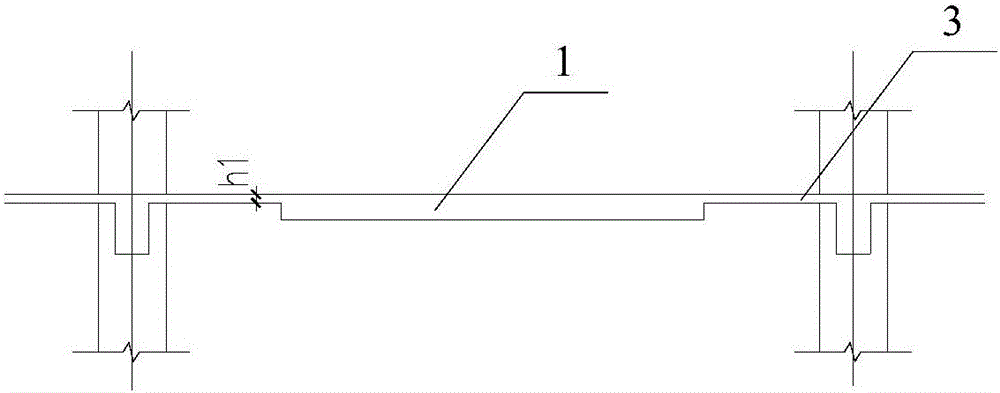

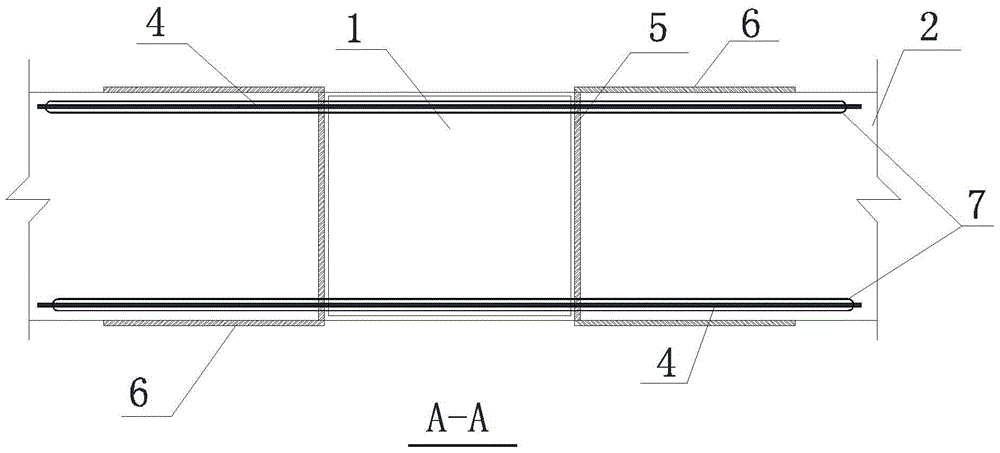

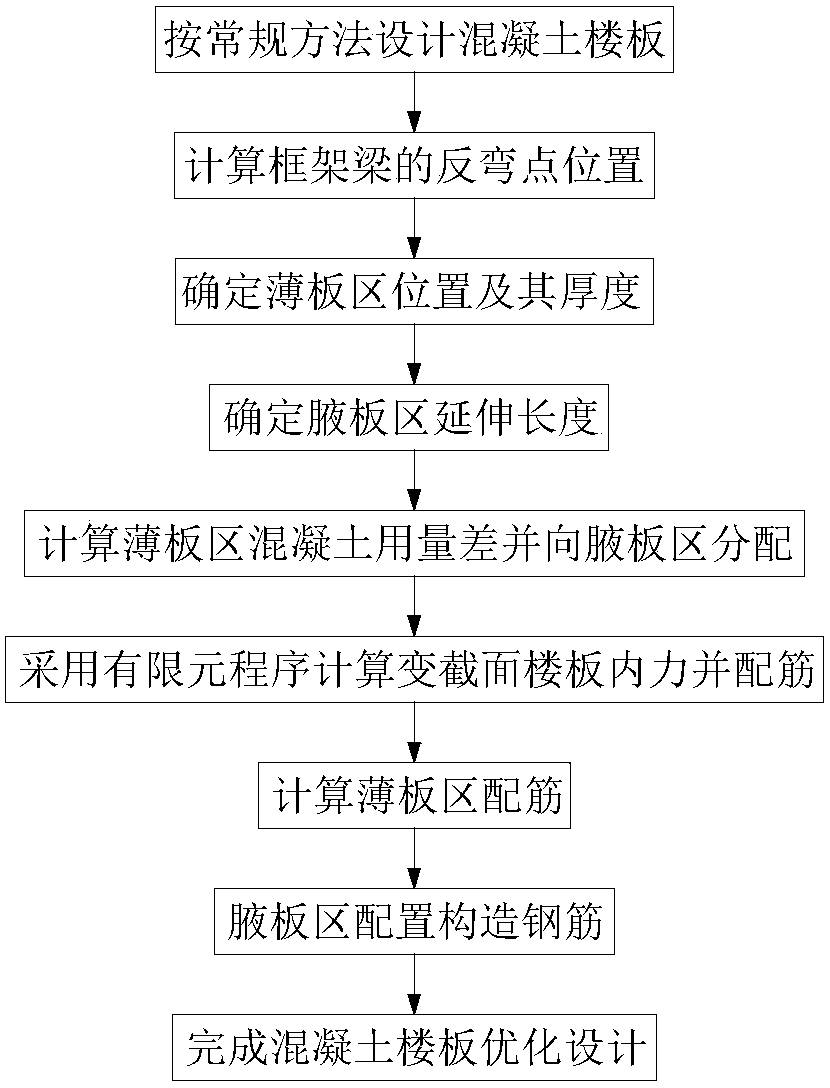

Concrete floor optimized design method capable of relieving earthquake damages on strong beams and weak columns

InactiveCN105714968AReduce earthquake damageMitigation of reinforcementConstruction materialFloorsStress levelEngineering

The invention discloses a concrete floor optimized design method capable of relieving earthquake damages on strong beams and weak columns. The concrete floor optimized design method mainly comprises the following steps: calculating a floor thickness according to a conventional design method; calculating the location of a framework beam inflection point; determining a thin plate area range, thicknesses of plates within the thin plate area and a haunch plate area range; calculating concrete use difference within the thin plate area range, and distributing concrete towards the haunch plate area range to form a variable-section floor; and carrying out variable-section floor reinforcement design and thin plate area reinforcement design, thereby completing the concrete floor optimized design capable of relieving earthquake damages on strong beams and weak columns. According to the design method, the section height and the reinforcement quantity of adjacent floors in a framework beam hogging moment zone are reduced, hogging moment stress level when floor reinforcing steel bars participate in a framework beam is reduced, earthquake damages, caused by floor reinforcing effect, on the strong beams and weak columns are effectively relieved or almost avoided, and the anti-seismic design demand of the strong beams and weak columns are met.

Owner:郭猛

Device of titanium metal wire net cage compounded with titanium metal wire engineering bone and preparation method thereof

ActiveCN102085123ALightweight yet strongExuberant formationBone implantCoatingsTitanium metalInvestment material

The invention provides a device of a titanium metal wire net cage compounded with a titanium metal wire engineering bone and a preparation method thereof, and the device of the titanium metal wire net cage compounded with the titanium metal wire engineering bone comprises a piston type titanium metal wire net cage and a titanium metal wire engineering bone composite filled in the piston type titanium metal wire net cage; and the preparation method comprises the following steps: winding titanium metal wire non-woven fabric on the outer wall of a titanium metal cage body and sintering for preparing a titanium metal wire net cage body, then coating hydroxyapatite on the inner surface and the outer surface of the cage body, and then placing two piston type cap-shaped bodies in an inner cavityof the metal cage body for getting the piston type titanium metal wire net cage; and further uniformly mixing titanium metal wires, a morselized bone, a binding material and auxiliary materials, and filling into the piston type titanium metal wire net cage. The device has good elastic modulus coordination and high strength, and can be used in the field of bone surgery.

Owner:HARBIN MEDICAL UNIVERSITY

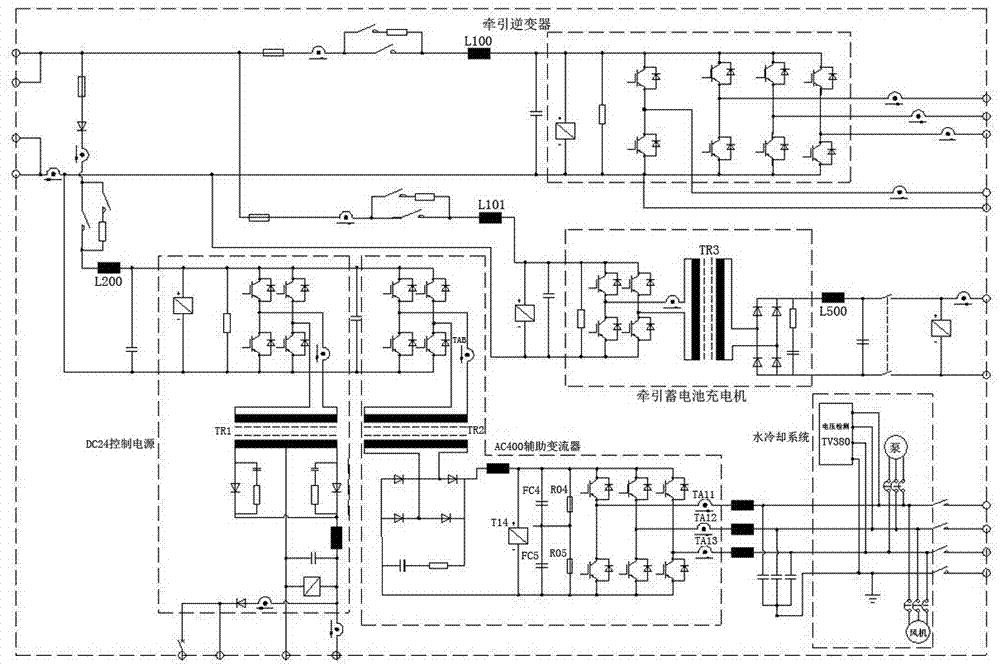

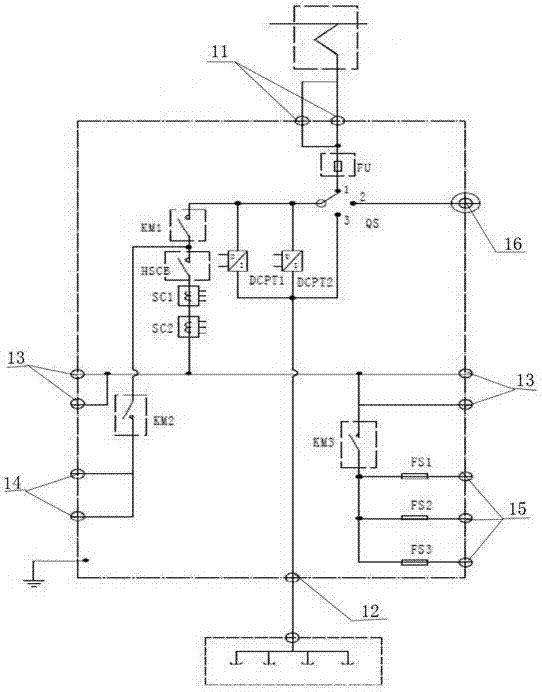

Electric transmission system of low-floor light rail vehicle

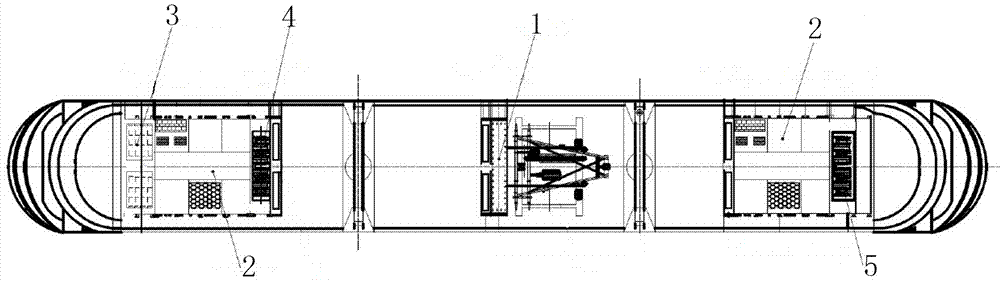

PendingCN107487220AFulfilling installation space requirementsMeet lightweight design requirementsElectric locomotivesPropulsion by batteries/cellsElectric power transmissionTransformer

The invention relates to electric transmission systems of vehicles, in particular to an electric transmission system of a low-floor light rail vehicle. The problem that a traditional electric transmission system cannot adapt to a low-floor light rail vehicle is solved. The electric transmission system of the low-floor light rail vehicle electric comprises a high-voltage box, two traction auxiliary converters, a brake resistor box, a 24V storage battery and a traction storage battery. The high-voltage box comprises a main fuse, an isolating switch and a high-speed circuit breaker. Each traction auxiliary converter comprises a traction inverter, a smoothing reactor, a DC24V control power supply, an AC400V auxiliary inverter and a traction storage battery charger, wherein transformers included in the DC24V control power supply, the AC400V auxiliary inverter and the traction storage battery charger are high-frequency transformers. The high-voltage box, the traction auxiliary converters and the brake resistor box are all of box-type design with the height being no more than 530 mm. The electric transmission system has the characteristics of being high in integration degree, small in size, high in reliability, good in seismic resistance, high in protection grade, powerful in function and the like.

Owner:CRRC YONGJI ELECTRIC CO LTD

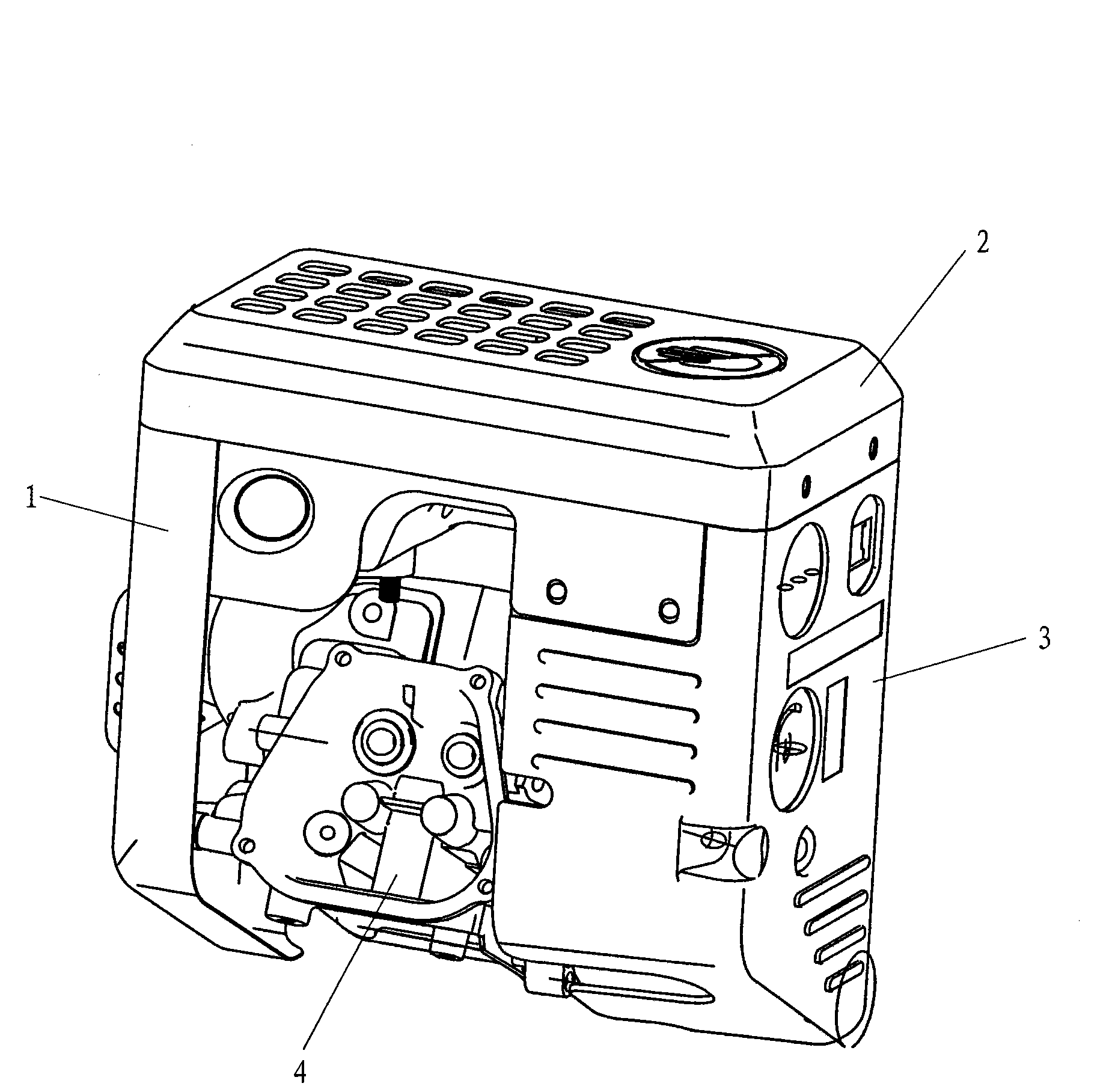

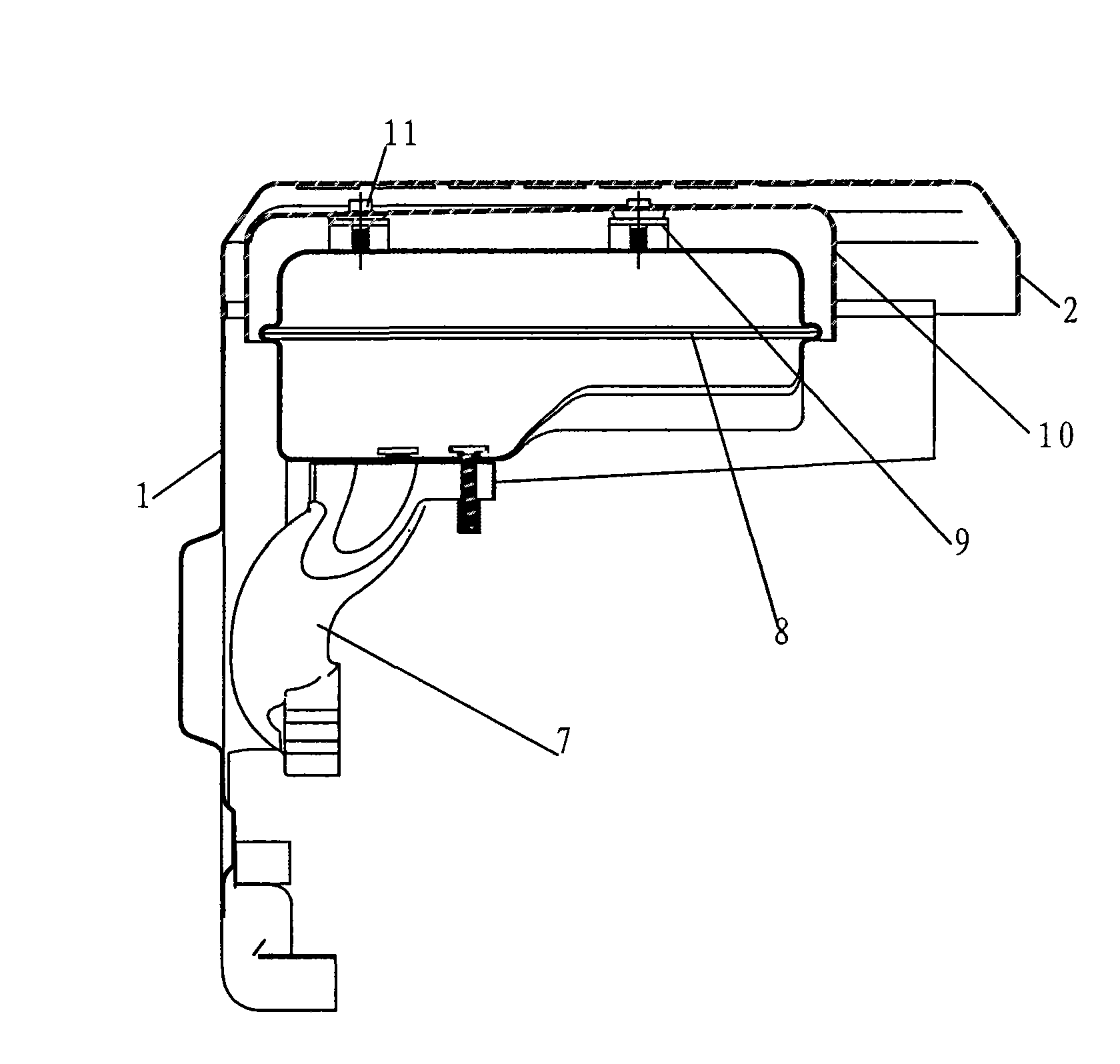

Mounting structure of muffler outer hood of snow remover

InactiveCN101576035AReduce the temperatureEliminate potential safety hazardsSnow cleaningIntake silencers for fuelMufflerAir filter

The invention relates to a mounting structure of a muffler outer hood of a snow remover, which comprises an inner hood, an outer hood, an air filter, a cylinder end and a muffler. The mounting structure is characterized in that the inner hood and a bracket at the top part of the muffler are connected by a bolt; the outer hood is arranged at the outside of the inner hood; one end of the outer hood is welded with one end of the outer hood of the muffler; the other end of the outer hood is connected with the shell of the air filter by a bolt; the cylinder end is fixed in the shell of the air filter, a protective hood and the inner hood by bolts. The adopted technical proposal leads the outer hood and the inner hood not to be contacted, avoids the heat of an engine from being directly transferred to the outer hood of the muffler and has the advantage of safe use.

Owner:LONCIN MOTOR

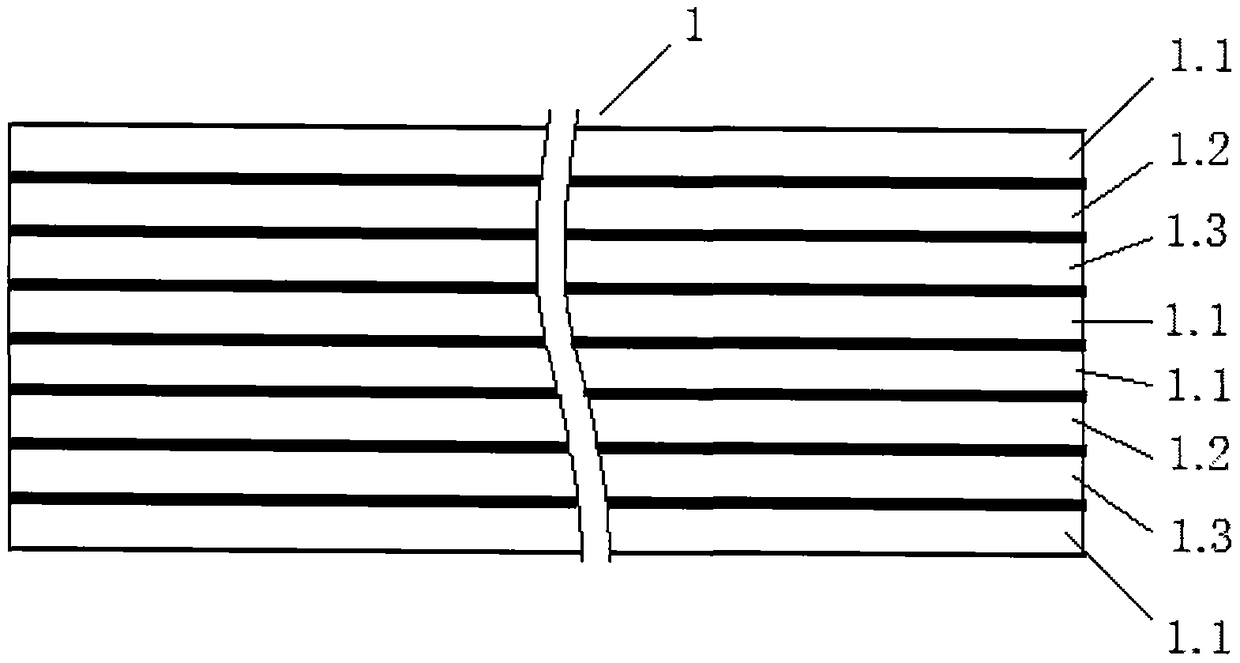

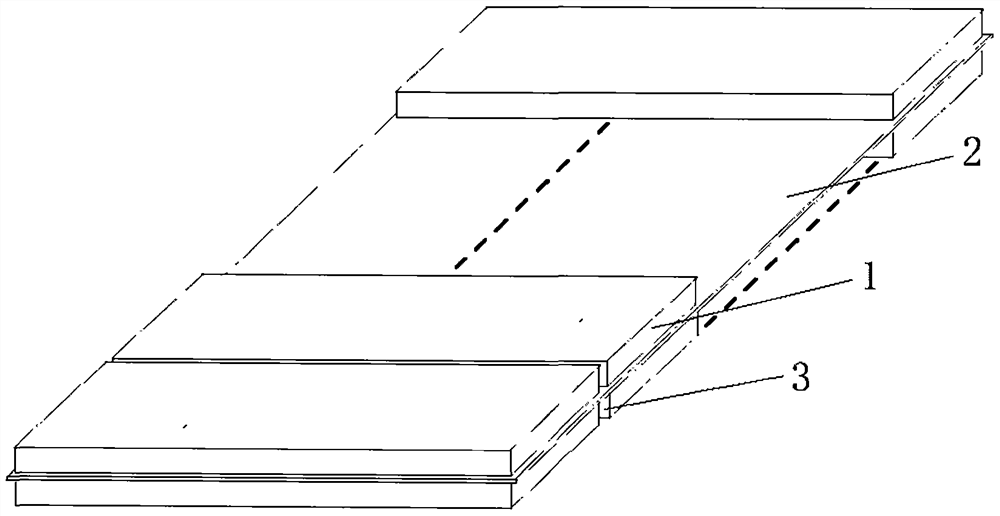

Folding-type airport emergency repair and construction composite combination way panel and manufacturing method thereof

ActiveCN109235177AHigh molecular weightHigh molecular weight polyethylene fiber, which has tensile breaking strengthHelicopter landing platformSynthetic resin layered productsFiberEpoxy

The invention provides a folding-type airport emergency repair and construction composite combination way panel and a manufacturing method thereof. The composite combination way panel is composed of asingle board and a connecting cloth. The veneer is a rectangular plate, which is laid side by side on the upper and lower surfaces of the connecting cloth, and the veneers on the upper and lower surfaces are symmetrically arranged; The veneer and the connecting cloth are bonded together by epoxy resin; Each veneer is made of composite fiber material, glass fiber cloth, ultra-high molecular weightpolyethylene fiber cloth and carbon fiber cloth. The composite pavement slab is light in material, the density is only 1.15-1.17, and the density is less than one sixth of ordinary steel plate. The bending strength of the panel is higher than 280MPa and the impact toughness is higher than 240K j / m2. The strength of the panel can satisfy the bearing capacity of the third generation fighter and allkinds of armed helicopters. The panel has the advantages of high bending strength, strong impact toughness, light material quality, large area, good anti-aging durability, simple and convenient repair pavement, time-saving and high efficiency of emergency repair, and can be used repeatedly.

Owner:NINGBO DACHENG ADVANCED MATERIAL +1

Concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and common reinforcement for connection

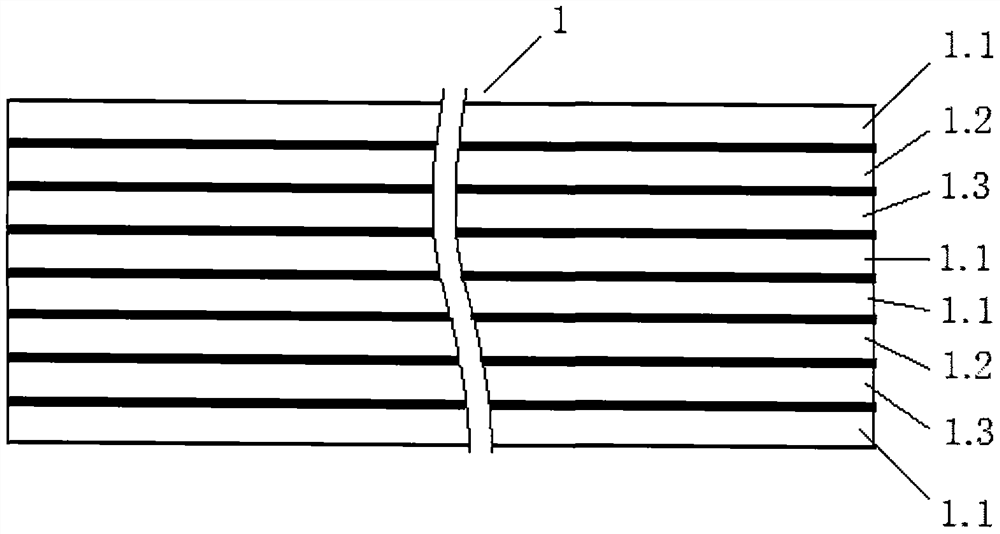

ActiveCN103924677AGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressConcrete beams

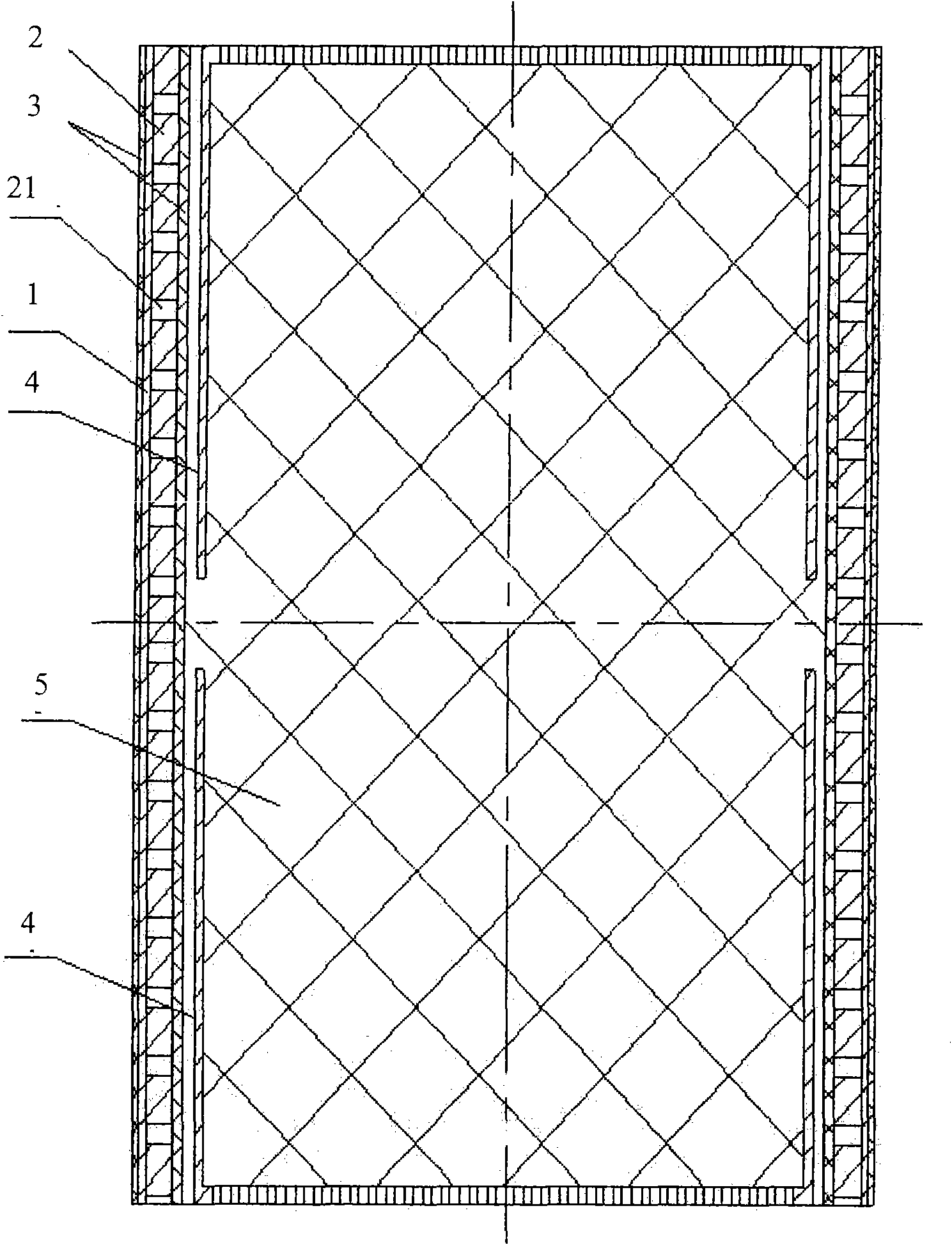

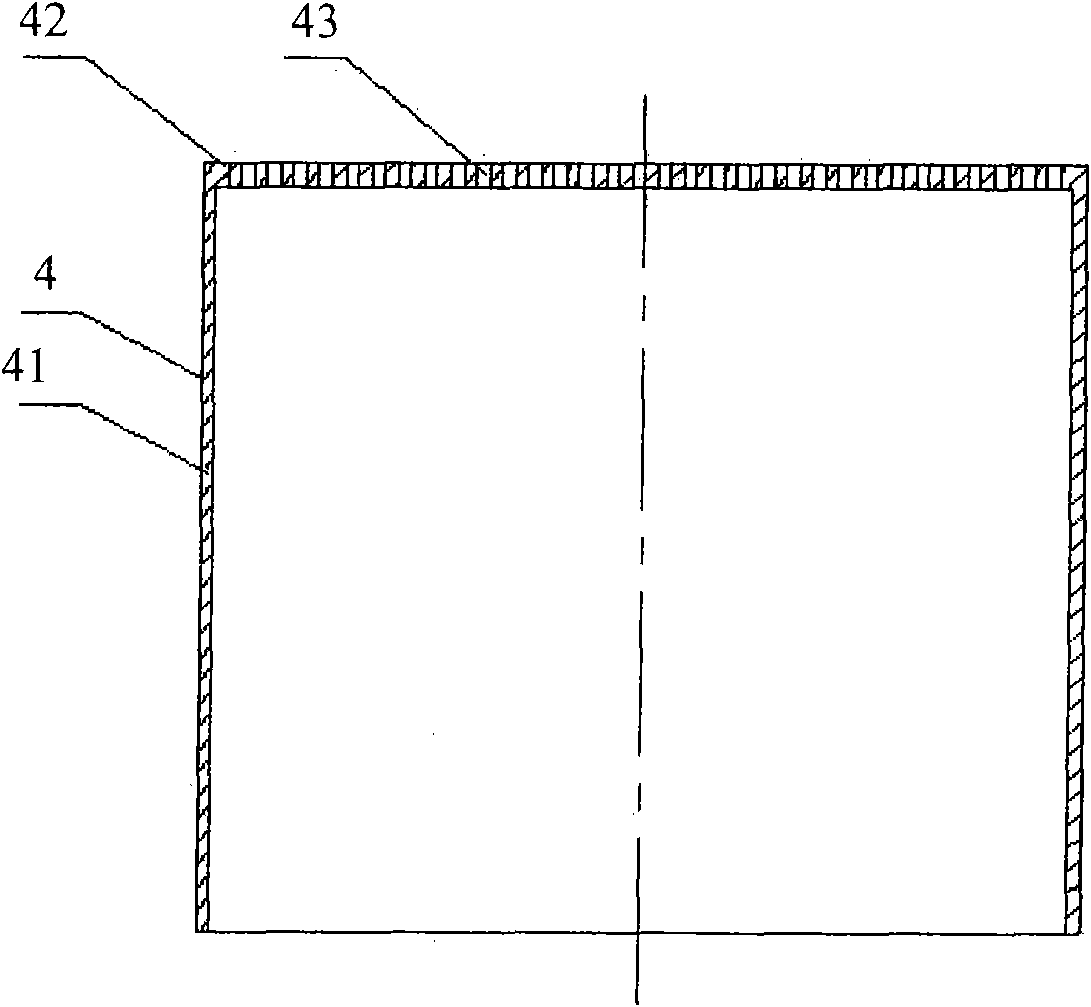

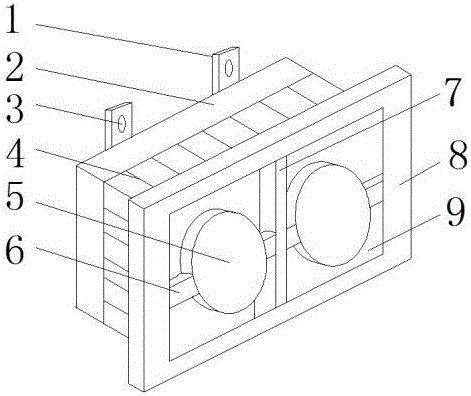

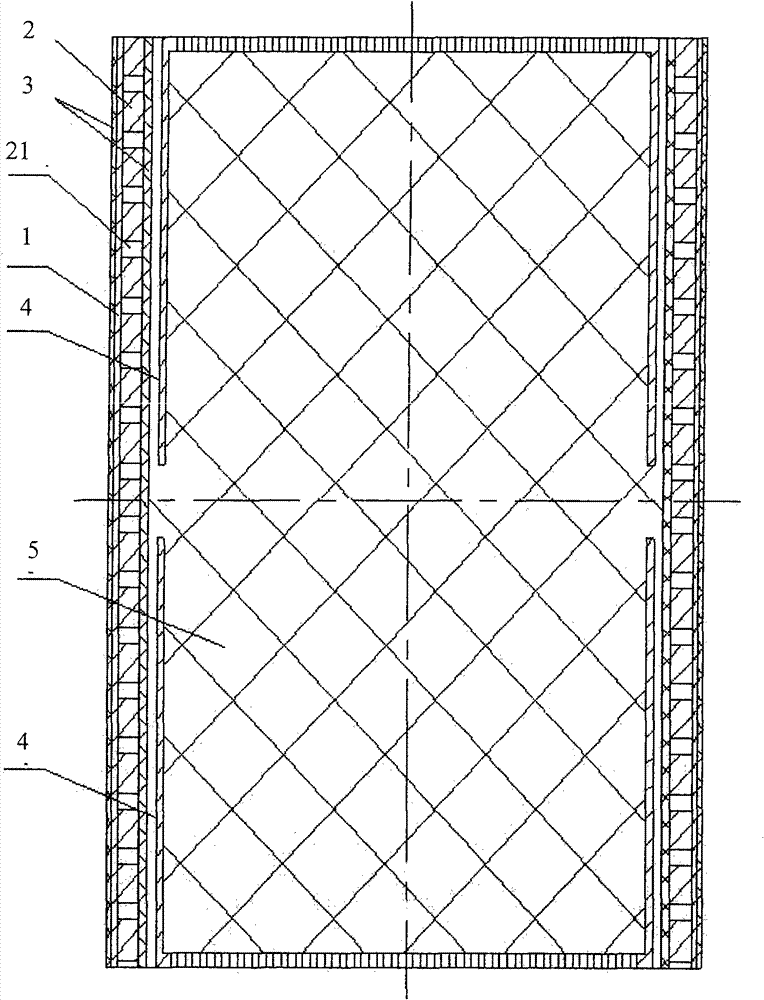

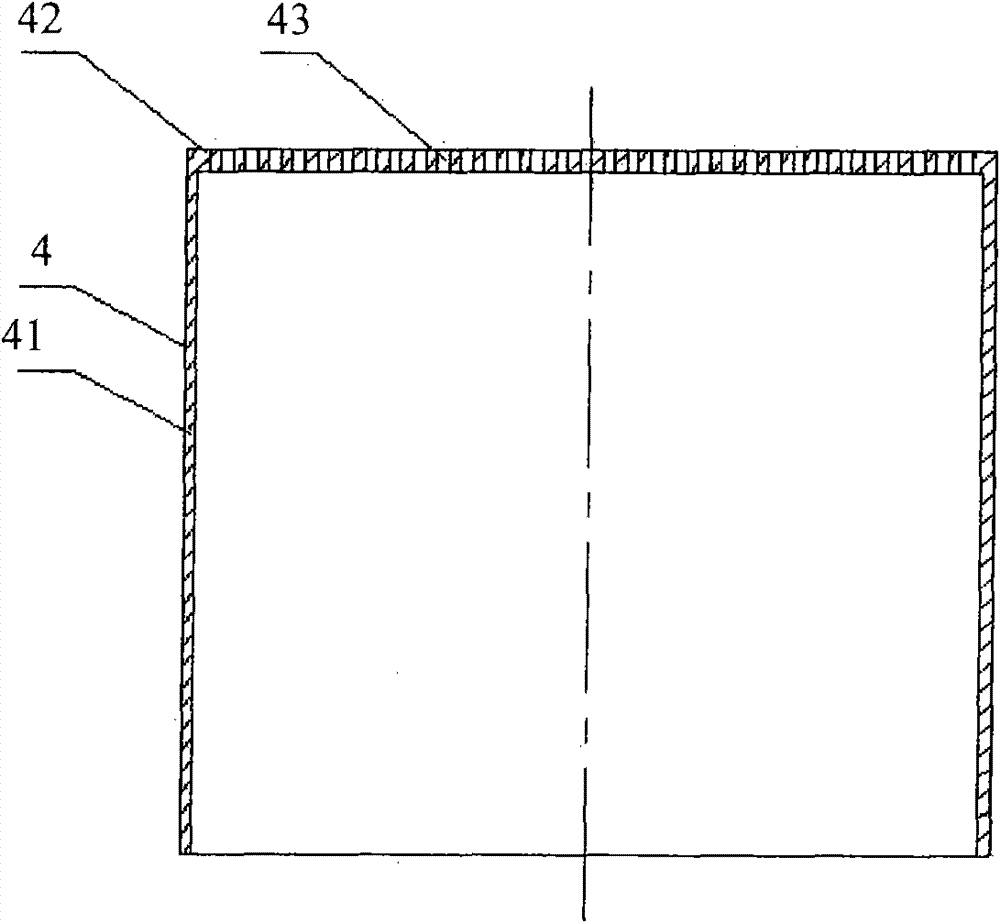

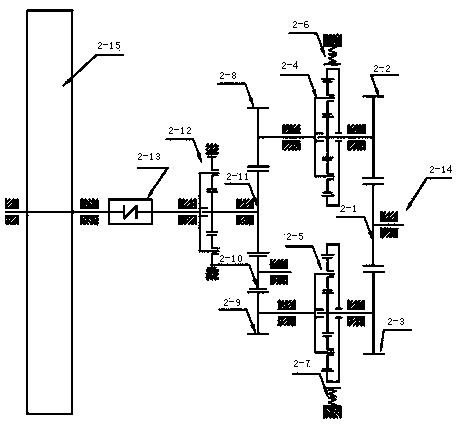

The invention relates to a concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection and belongs to the technical field of building structures. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, unbonded prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are both cast in place. The connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam is provided with ducts in which metal bellows are embedded; the steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam and are provided with corresponding holes; the steel channels are welded on the square-rectangular concrete-filled steel tube column. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability can be guaranteed, seismic performance is good, a connection way of the joint is applicable to side column joints in structures and also applicable to middle column joints, and the joint has promising application prospect.

Owner:北京中联浩科技服务有限公司

Composite concrete building casing member and plate, and their combining method

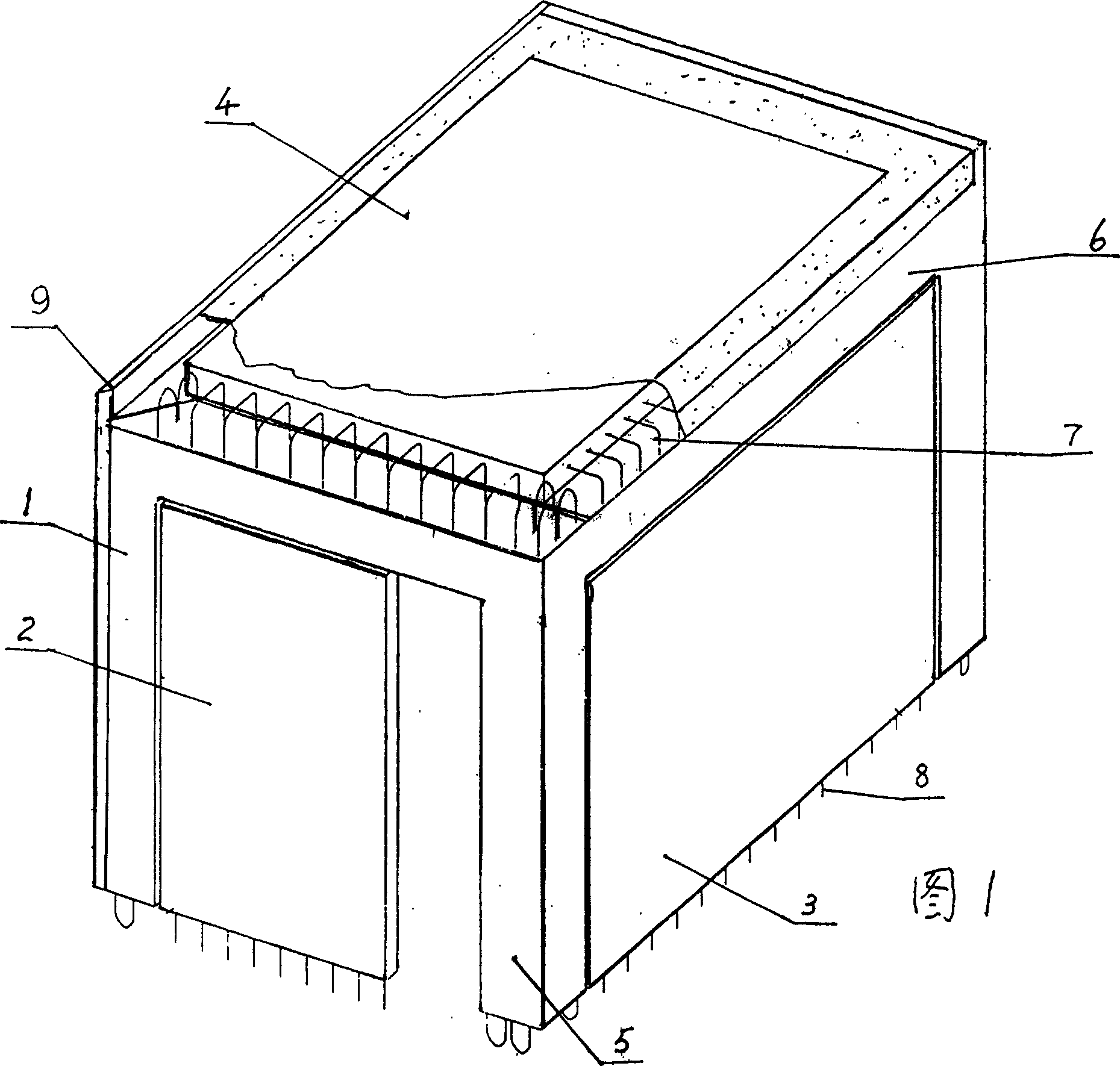

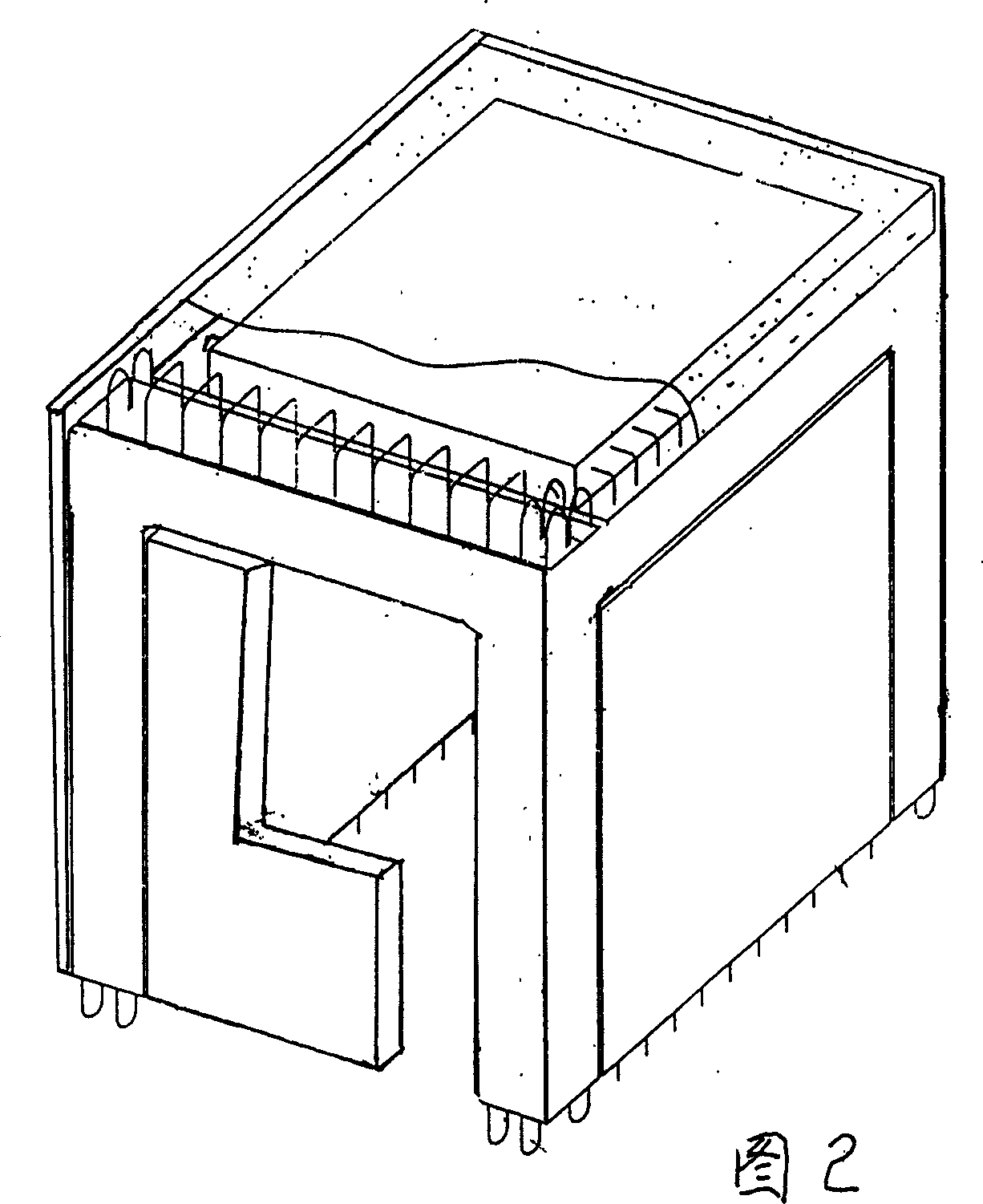

InactiveCN1644824ALight weightLight base loadBuilding constructionsSmall buildingsReinforced concretePolystyrene

A kind of box-type structural members and slabs for the combined building without balcony and staircase is disclosed. Said box-type structural member is a pentahedron made of reinforced concrete and has the insulating foam polystyrene board on its external surfaces. Its wall and roof are the prefabricated slabs made of aerated reinforced concrete prepared from powdered coal ash and cement. Its column, beam and ribbed beam are the prefabricated concrete members. Its combining technology includes such steps as arranging said members in a combining foam, coupling anchors, binding, welding, inserting spiral reinforcing bars, and casting concrete.

Owner:郭金鸿

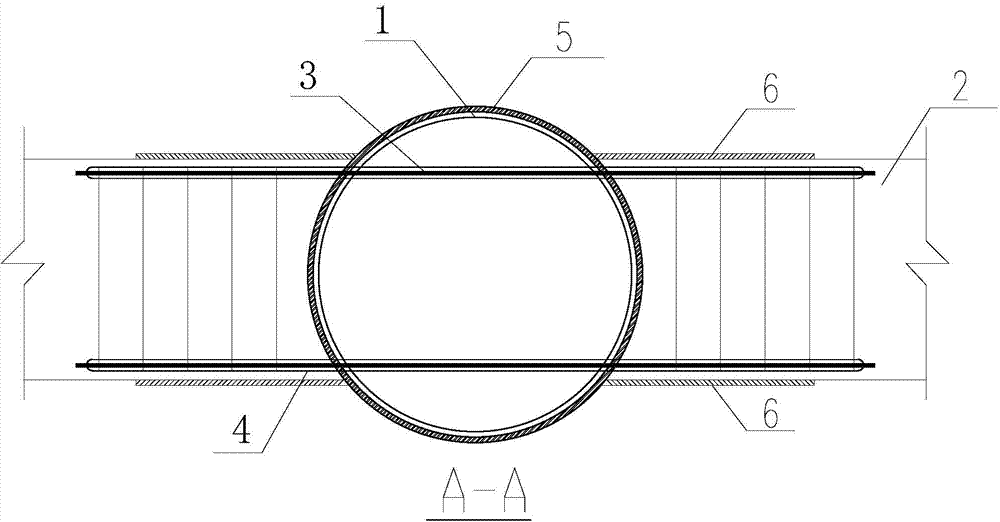

Circular concrete-filled steel tubular column node of unbonded pre-stressing connecting concrete beam

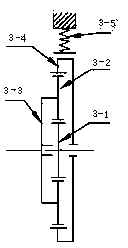

InactiveCN103924682AFast constructionGuaranteed reliabilityBuilding constructionsSteel tubePre stressing

The invention relates to a circular concrete-filled steel tubular column node of an unbonded pre-stressing connecting concrete beam, and belongs to the technical field of building structures. The circular concrete-filled steel tubular column node comprises a circular concrete-filled steel tubular column, a reinforced concrete beam, unbonded pre-stressing tendons, an annular plate and channel steel. The circular concrete-filled steel tubular column and the reinforced concrete beam are both formed in a cast-in-situ mode and connected through the unbonded pre-stressing tendons; a hole way is reserved in the connecting position of the circular concrete-filled steel tubular column and the reinforced concrete beam, and a metal corrugated pipe is embedded in the hole way; the annular plate is welded to the connecting position of the circular concrete-filled steel tubular column and the reinforced concrete beam, and a corresponding hole is formed in the annular plate; the channel steel is welded to a circular steel tube. By means of the circular concrete-filled steel tubular column node, the site welding technology is not needed, the reliability of node connection can be guaranteed, the node has the good shock resistance, the node connecting mode can be used for side column nodes in the structure and can also be used for middle column nodes, and the application prospect is wide.

Owner:BEIJING UNIV OF TECH

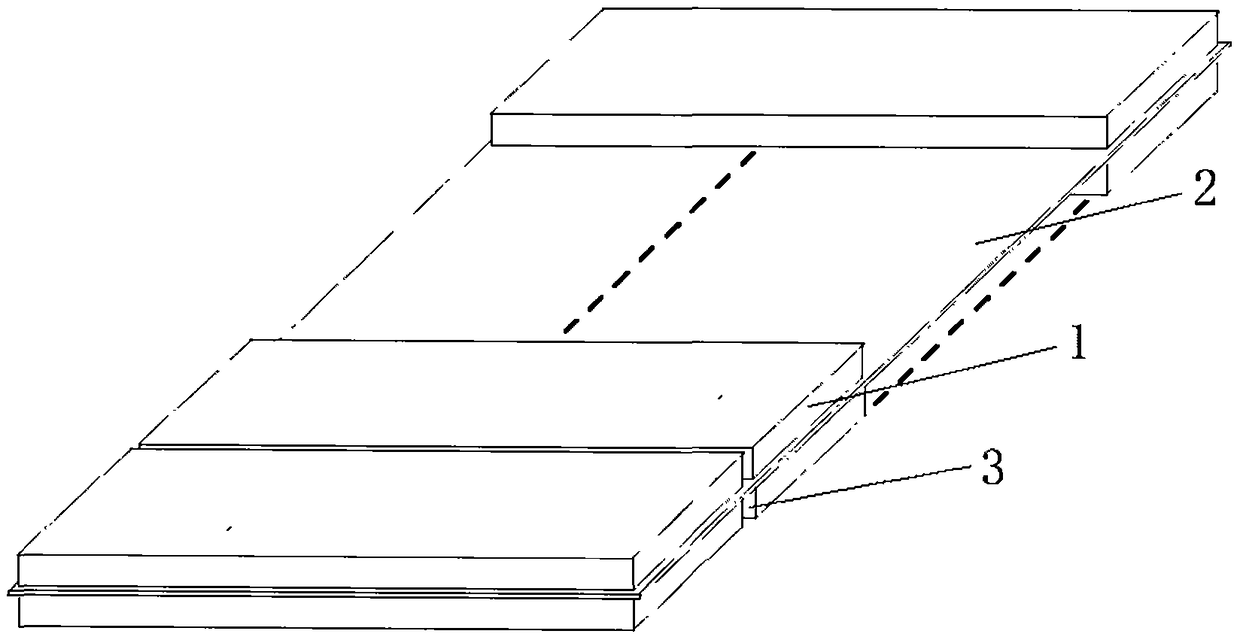

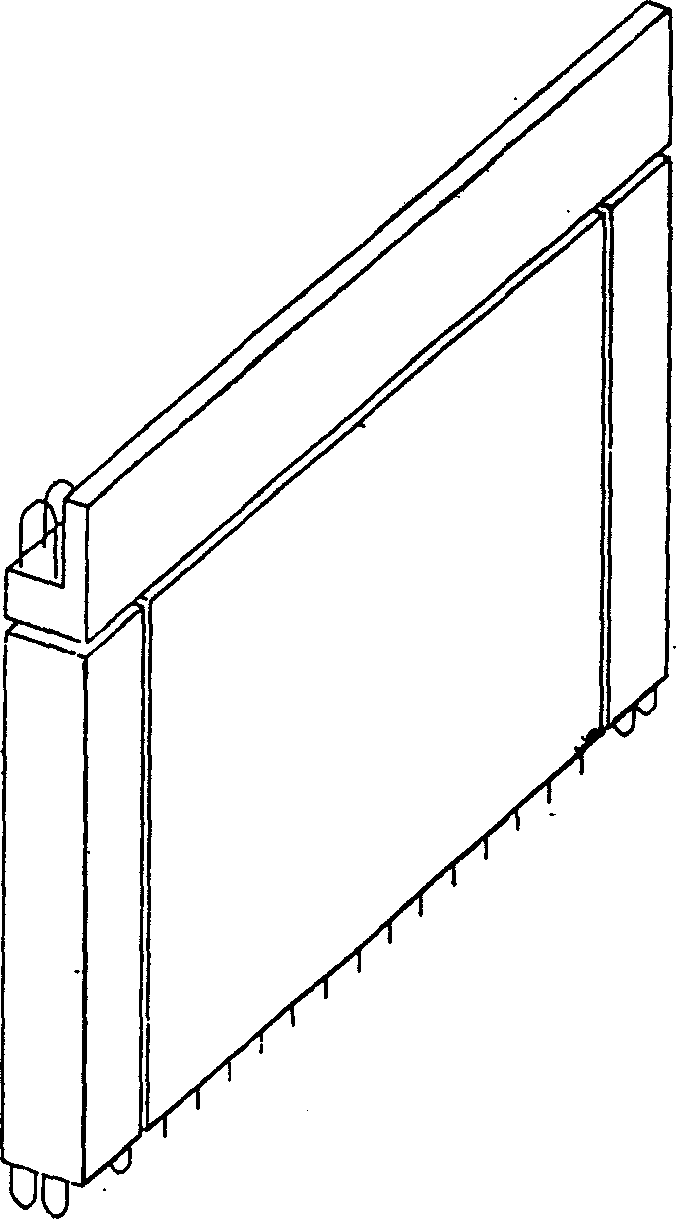

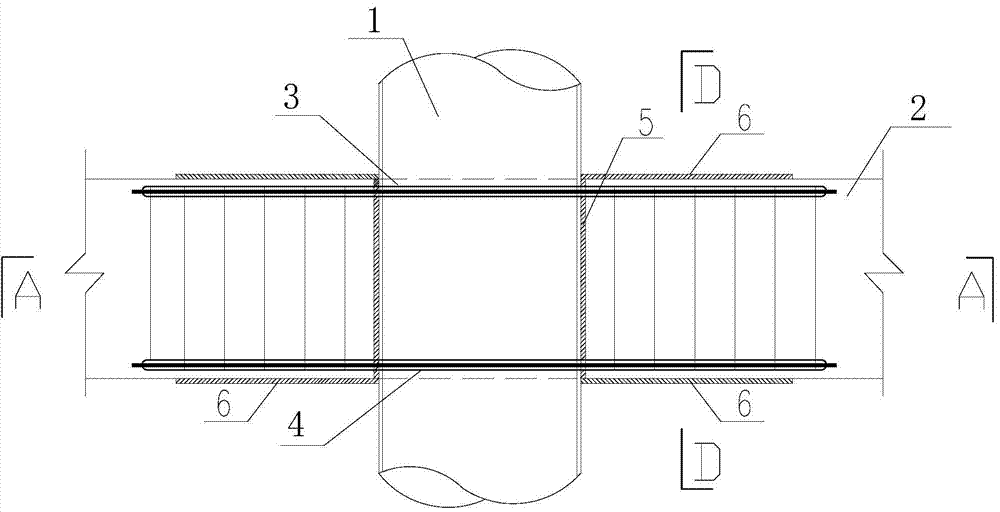

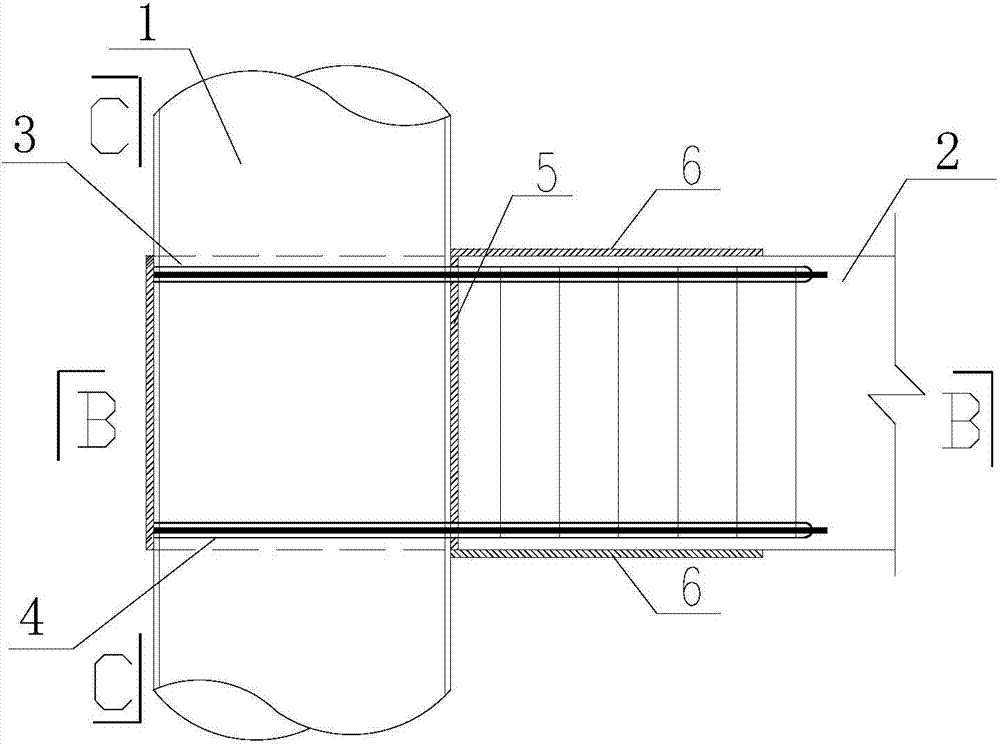

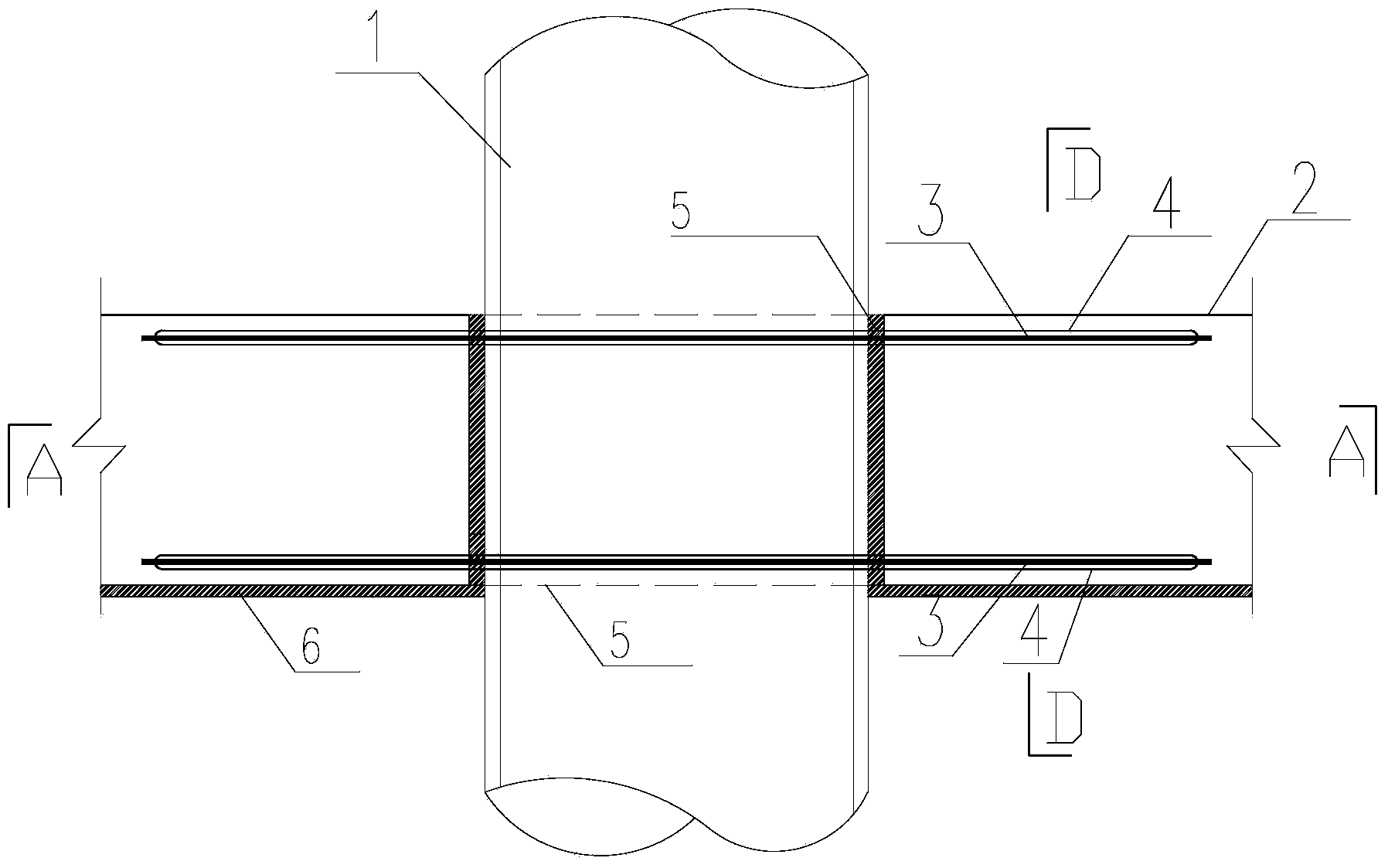

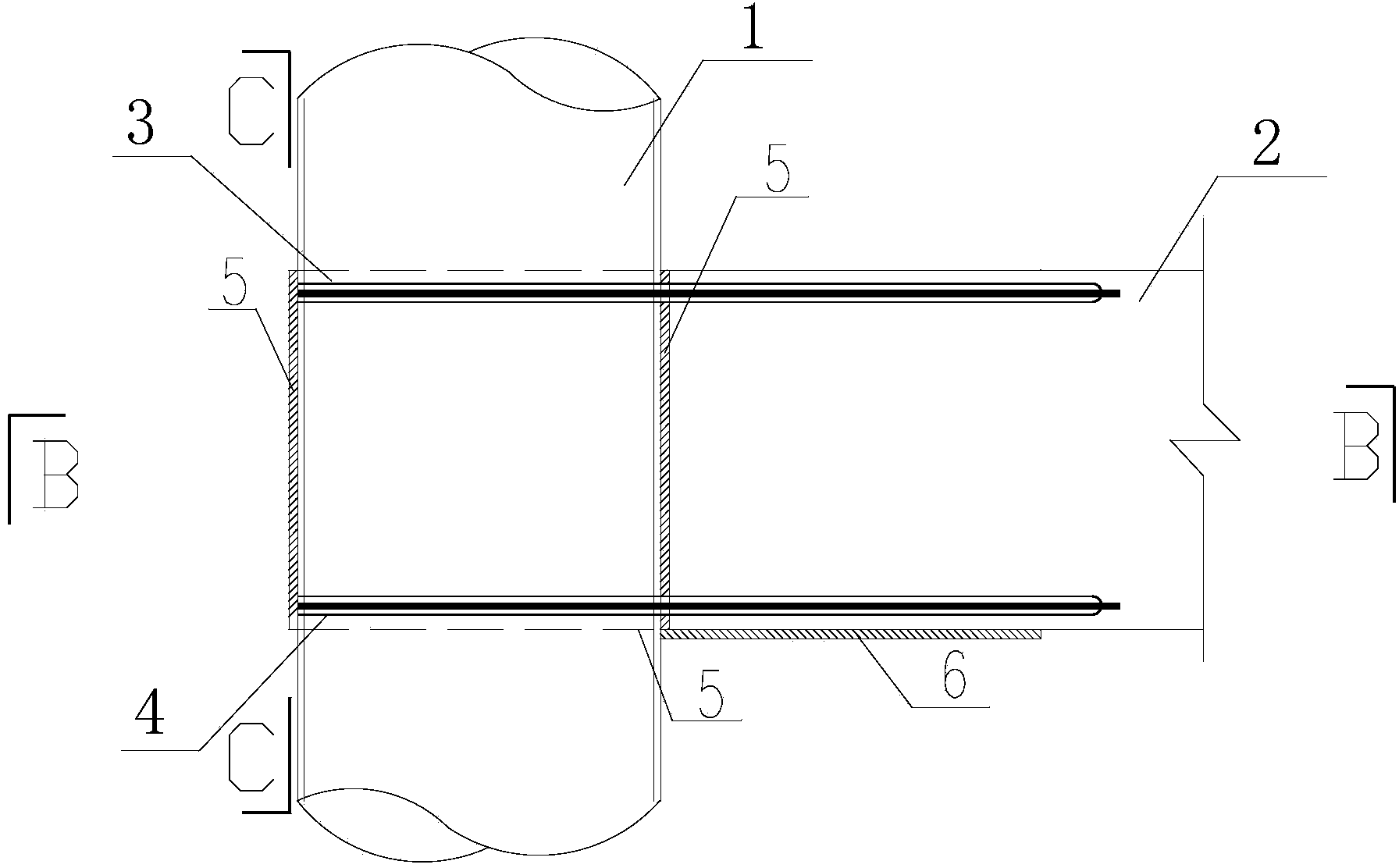

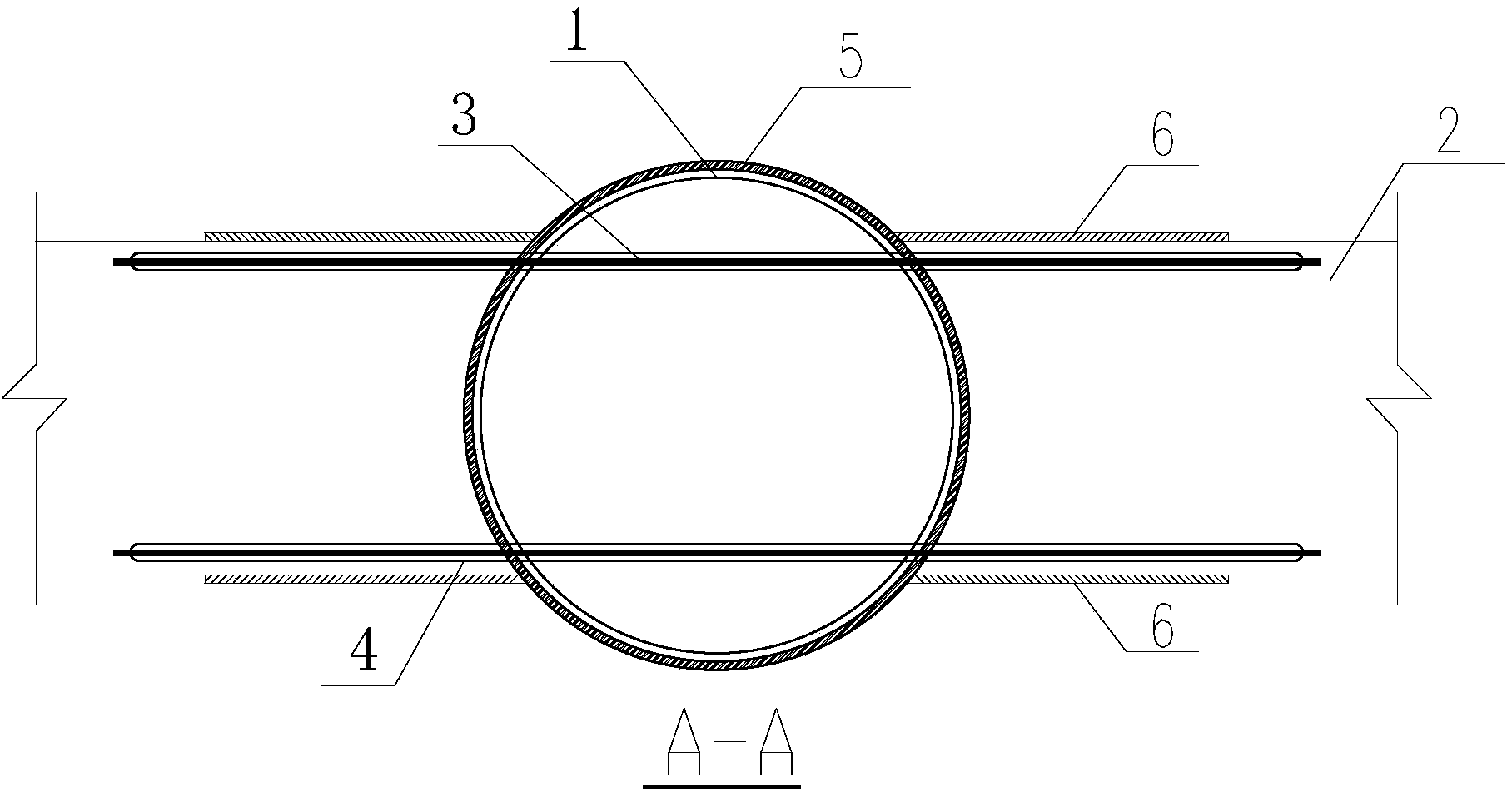

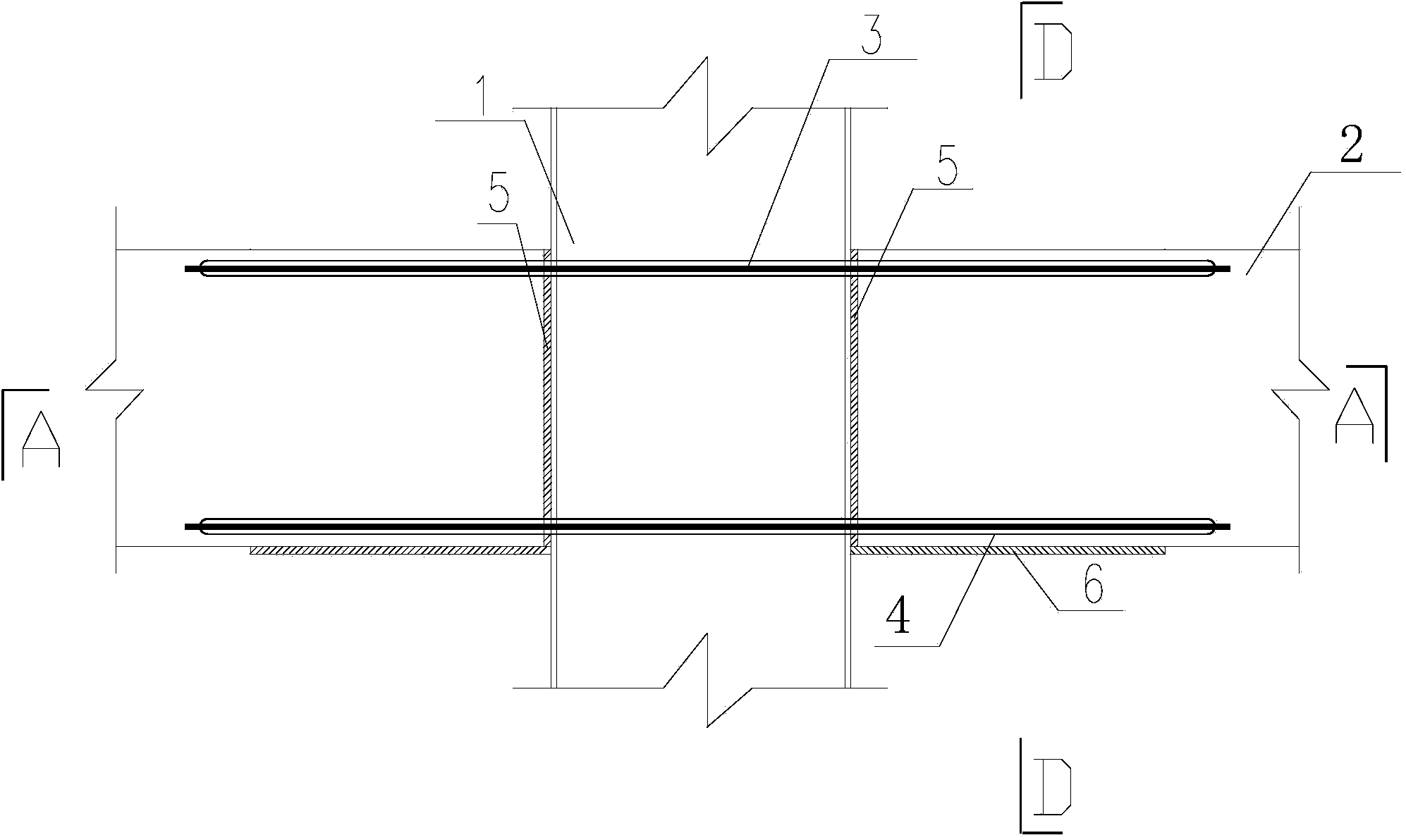

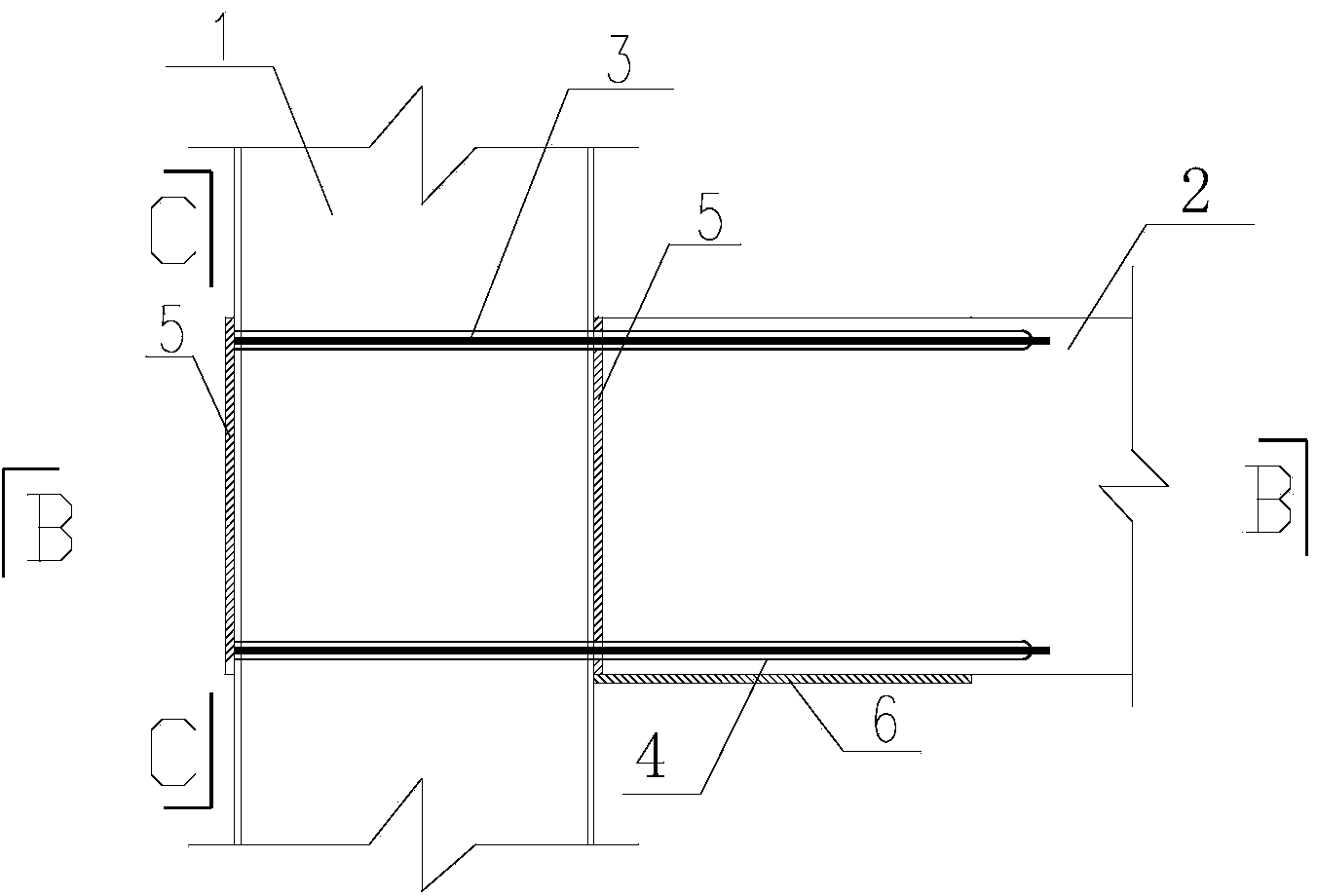

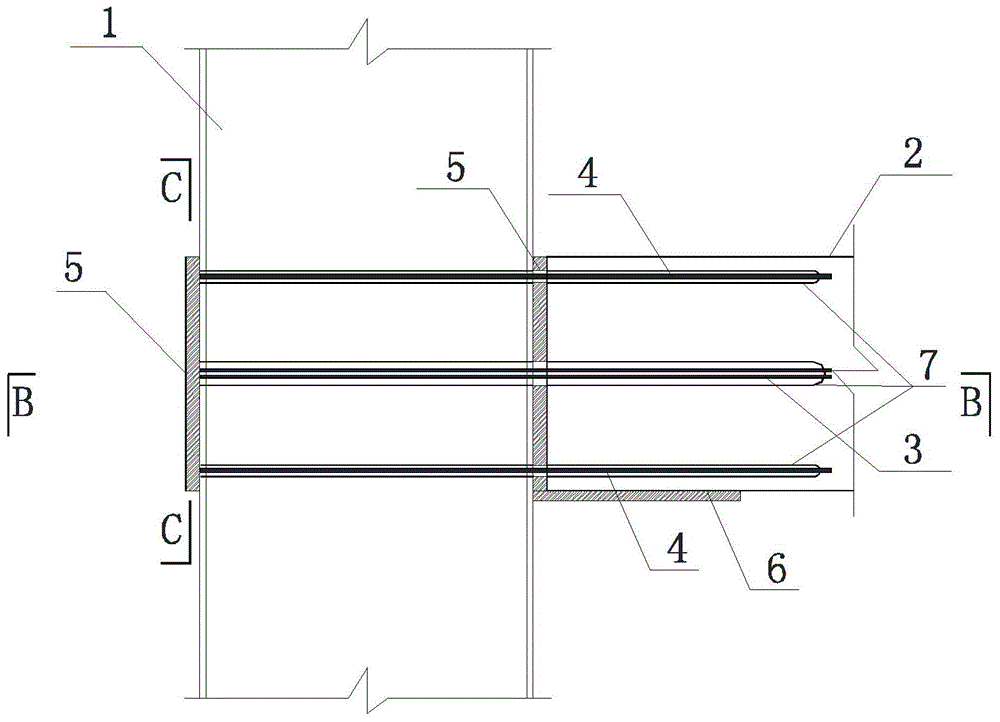

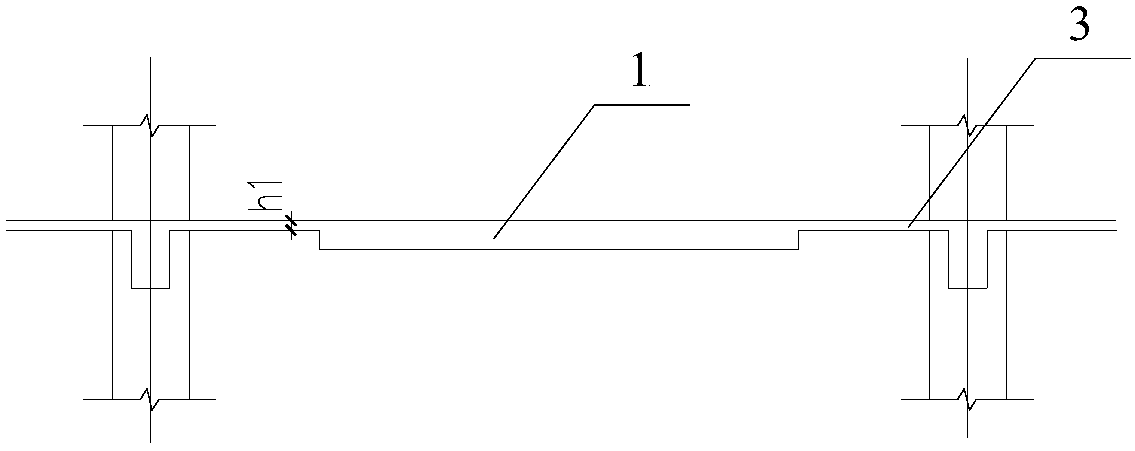

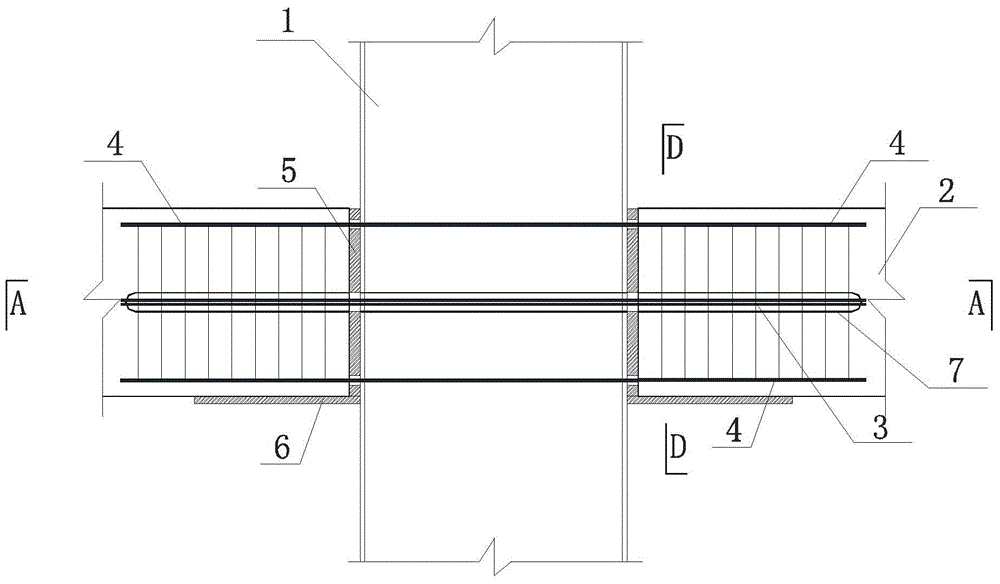

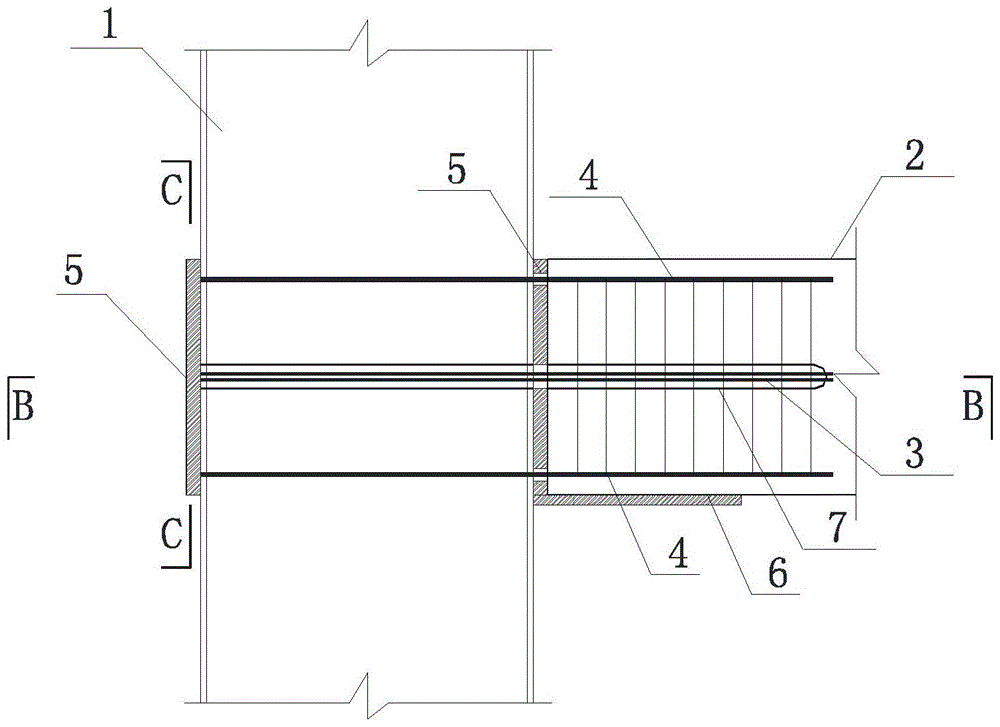

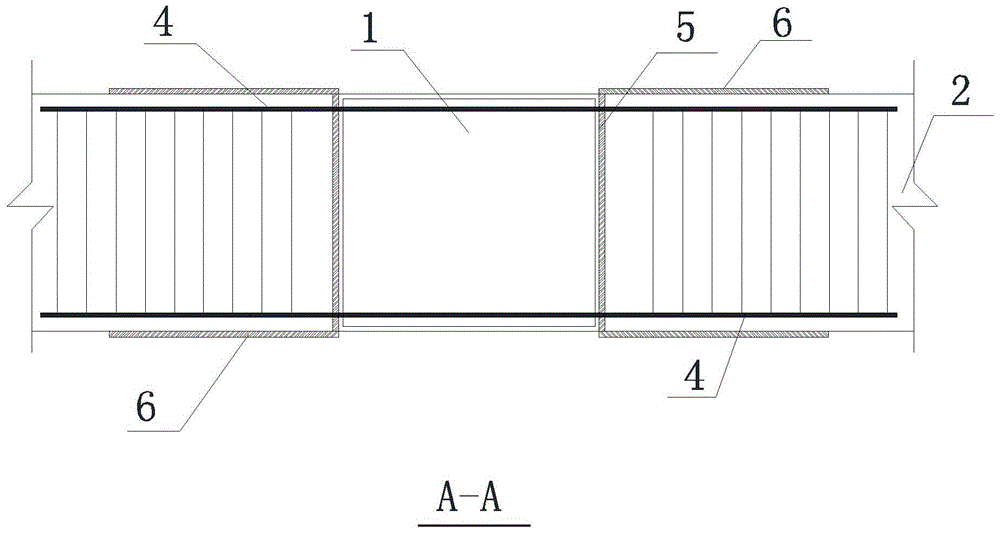

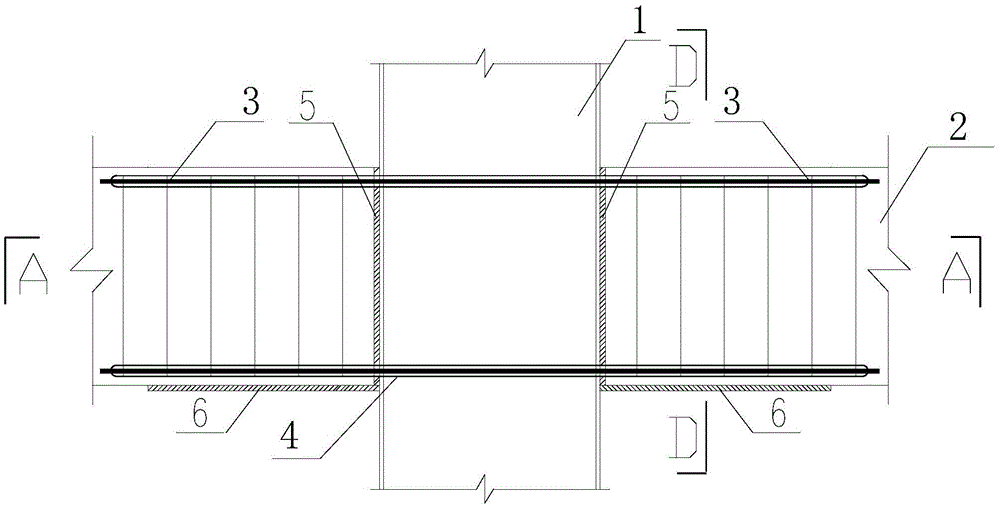

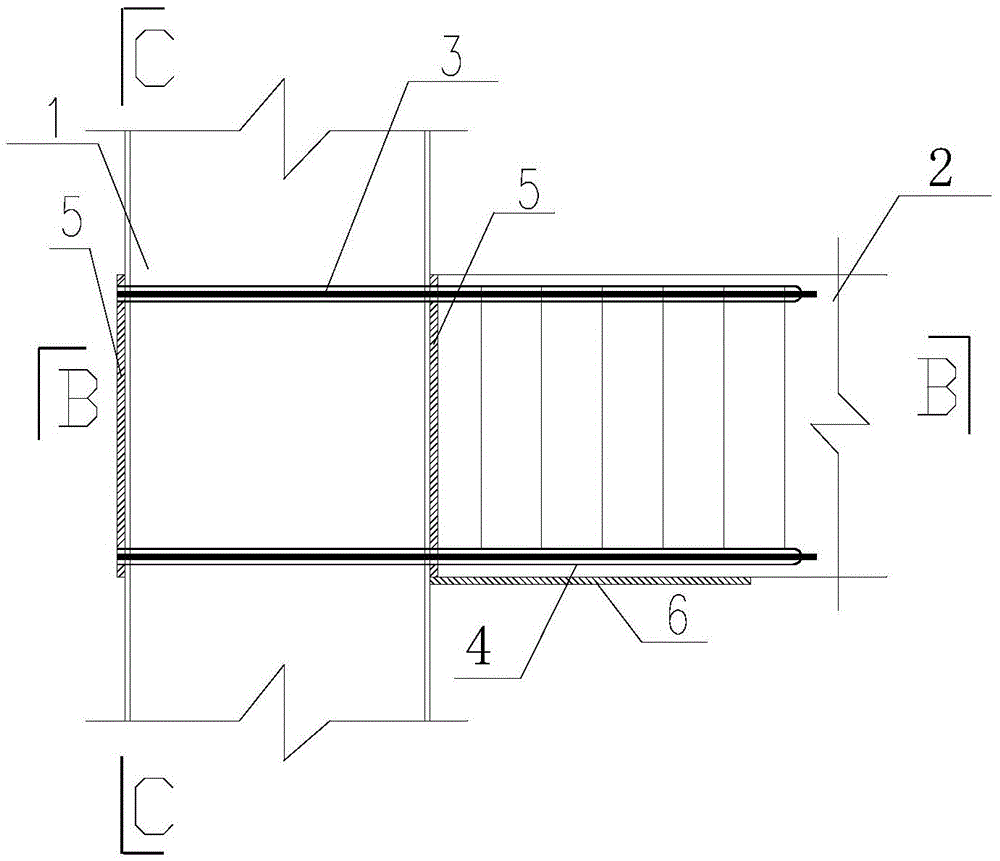

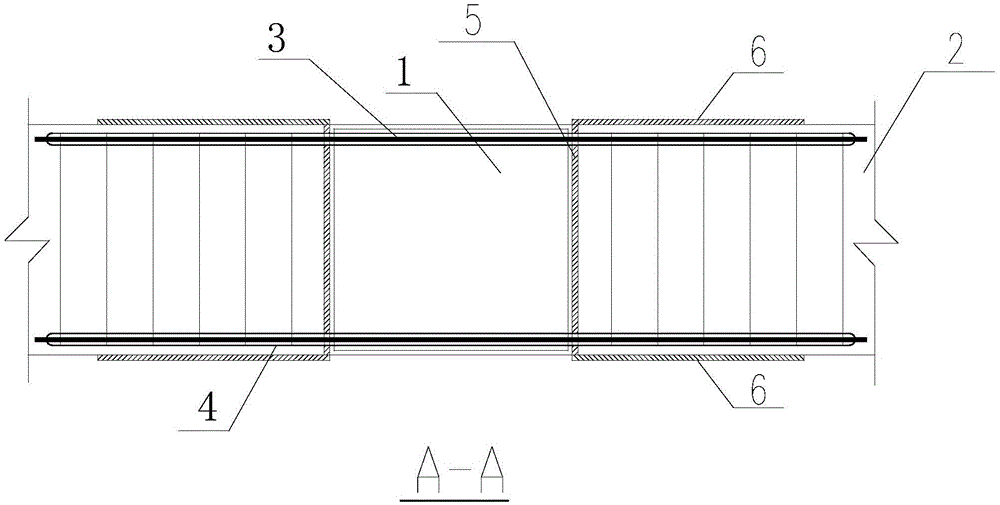

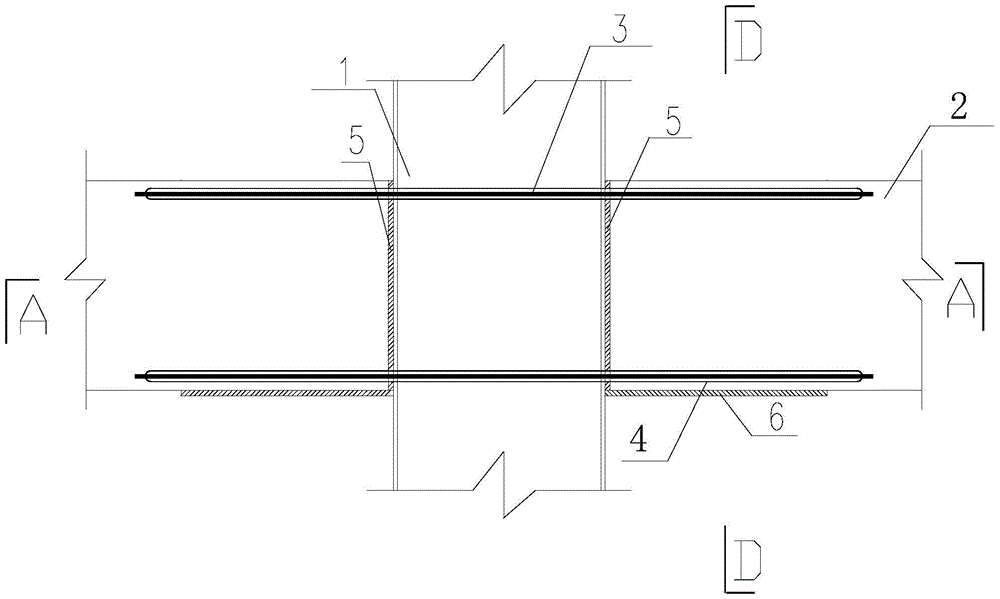

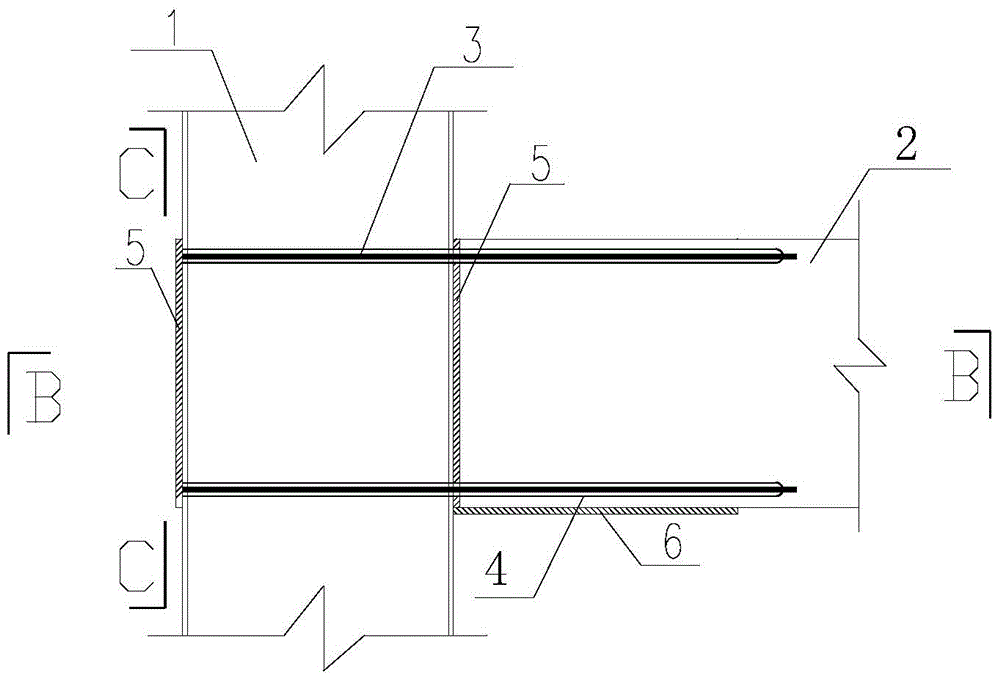

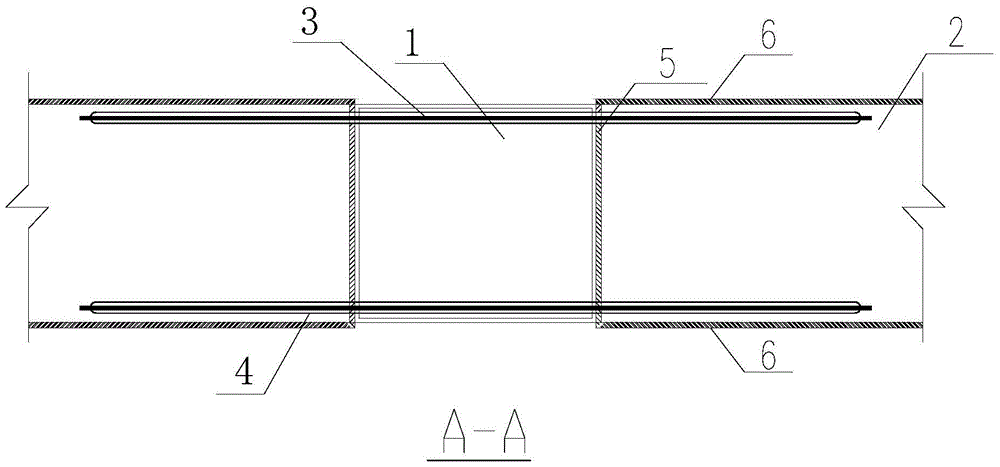

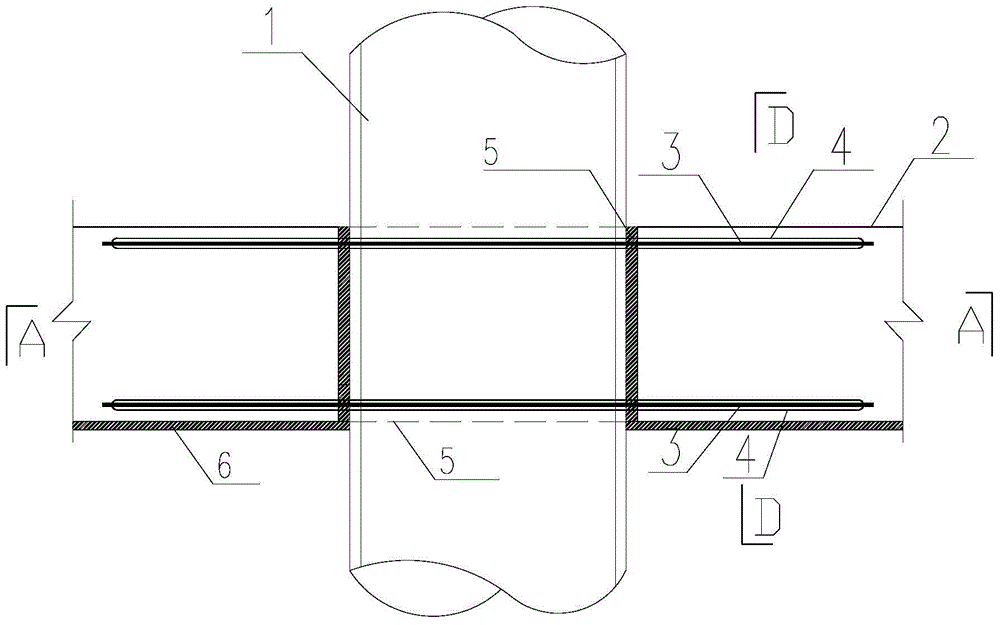

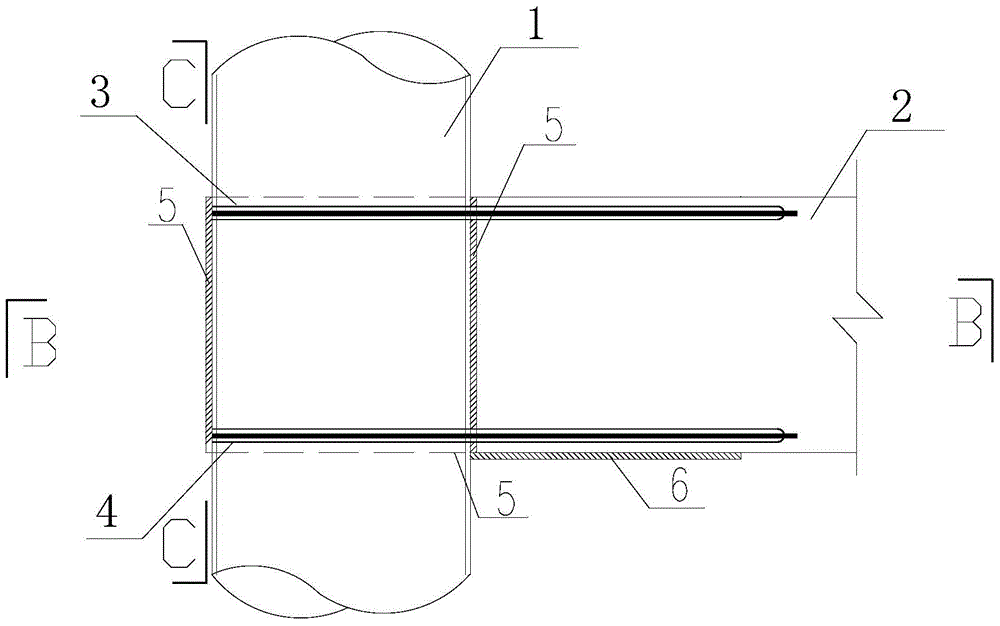

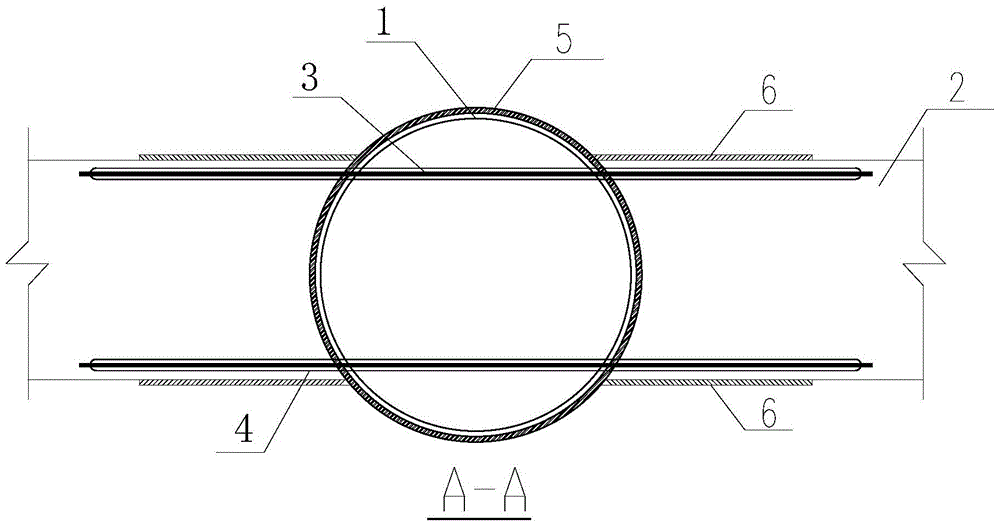

Node for connecting prefabricated concrete beam with round steel tube concrete column through unbonded prestressed ribs

ActiveCN103938729AGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressConcrete beams

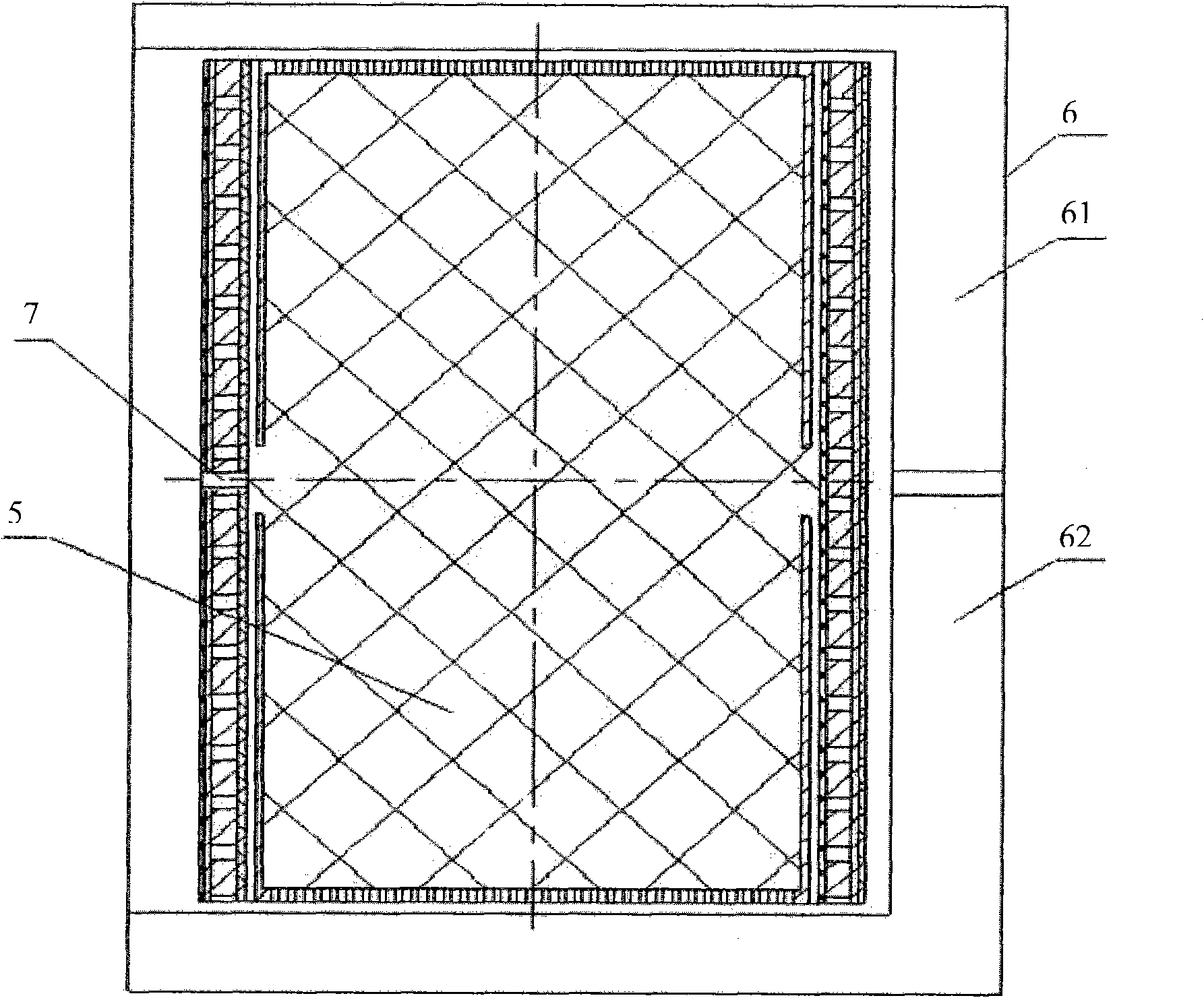

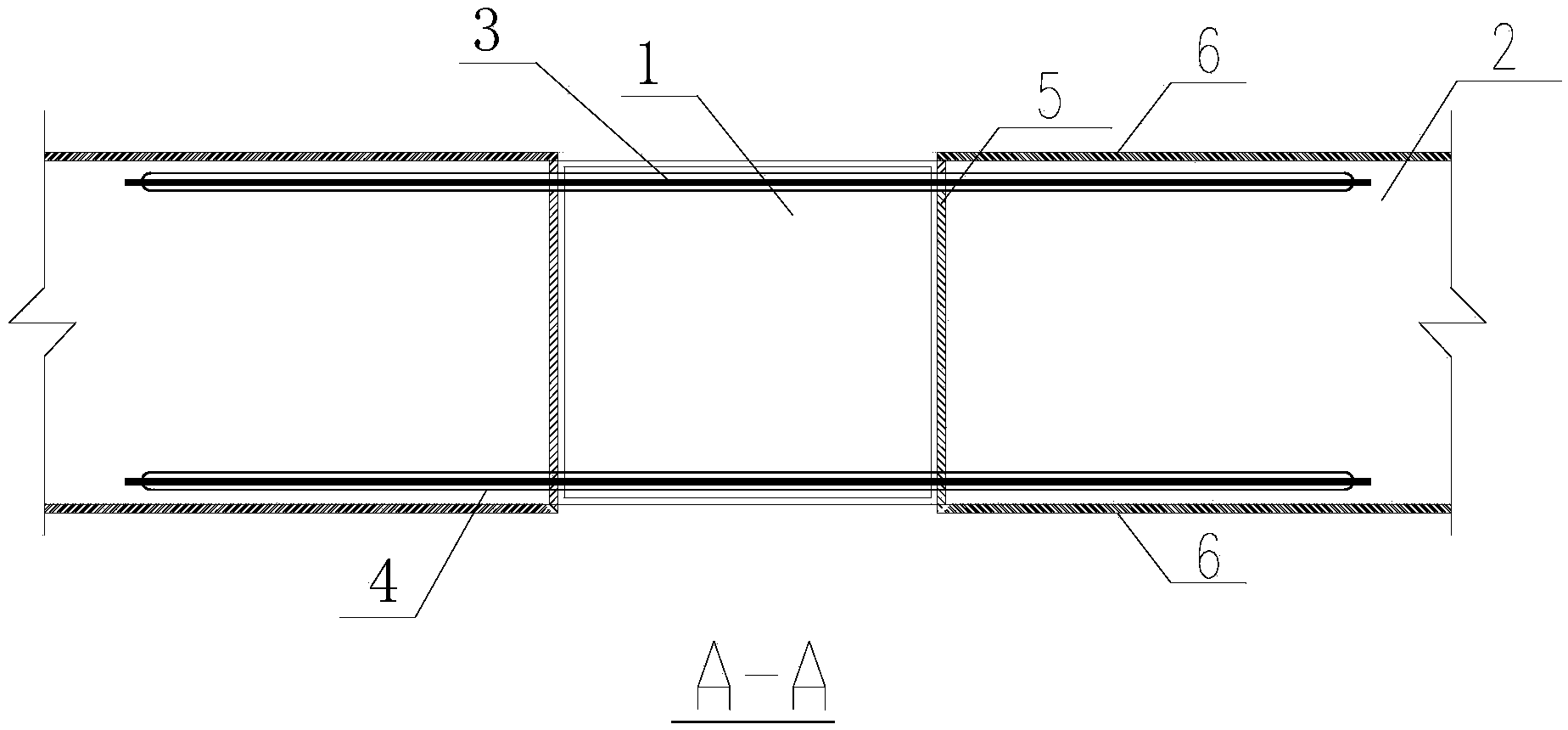

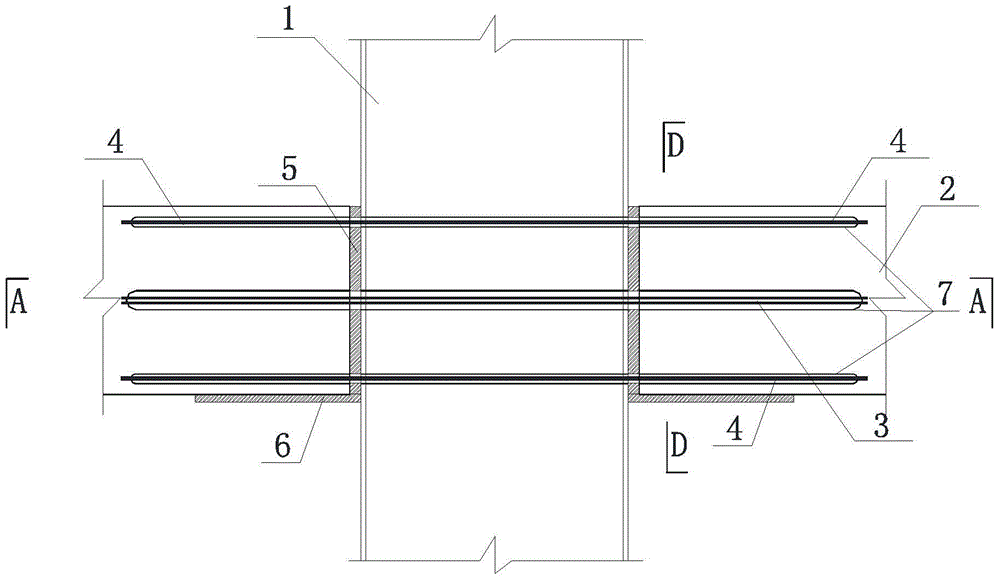

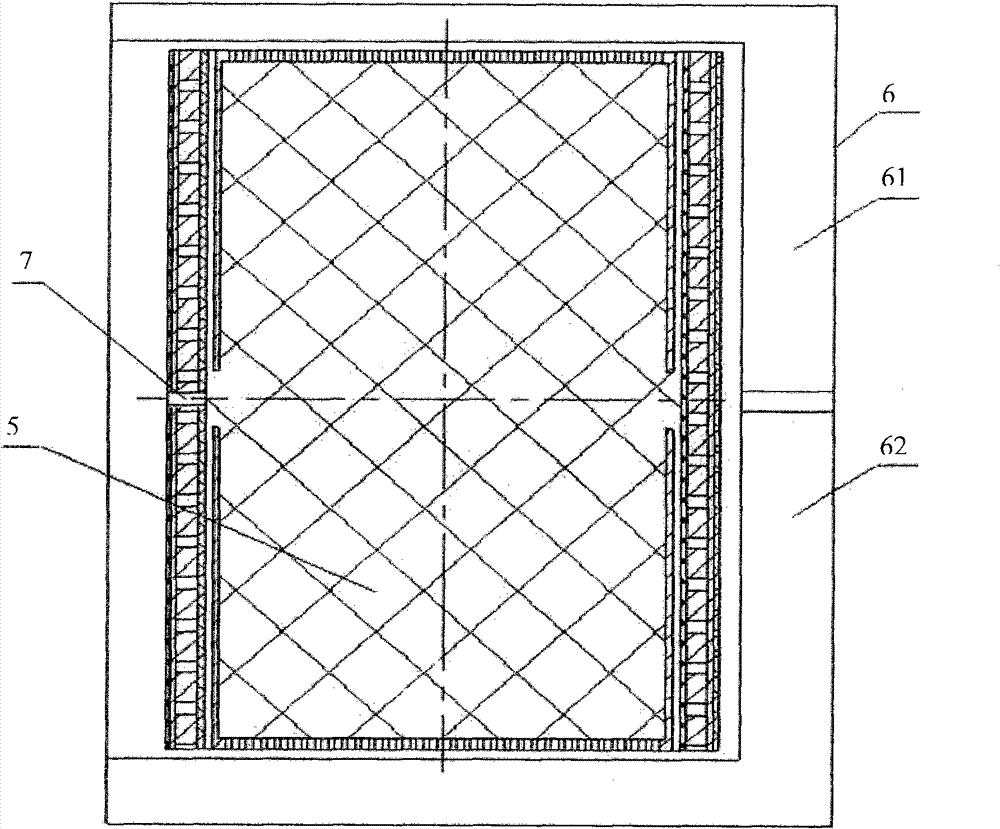

The invention provides a node for connecting a prefabricated concrete beam with a round steel tube concrete column through unbonded prestressed ribs, and belongs to the technical field of building structures. The node comprises the round steel tube concrete column, the reinforced concrete beam, the unbonded prestressed ribs, an annular plate and channel steel. The round steel tube concrete column (1) and the reinforced concrete beam (2) are both prefabricated; the positions, corresponding to beam sections, of the reinforced concrete beam and of the round steel tube concrete column are provided with hole channels; metal corrugated tubes (4) are pre-buried in the hole channels; the portion, connected with the reinforced concrete beam (2), of the round steel tube concrete column (1) is provided with the annular plate in a welded mode; the channel steel (6) is welded to a round steel tube; the unbonded prestressed ribs (3) penetrate through the metal corrugated tubes (4) and are tensioned so that the beam and the column can be connected into a whole. The construction speed is high, the onsite welding process is needless, reliability of node connection can be guaranteed, good anti-seismic performance is achieved, the node connection mode can be used for a side column node in a structure and can also be used for a middle column node and application prospects are wide.

Owner:南京易蔚均科技有限公司

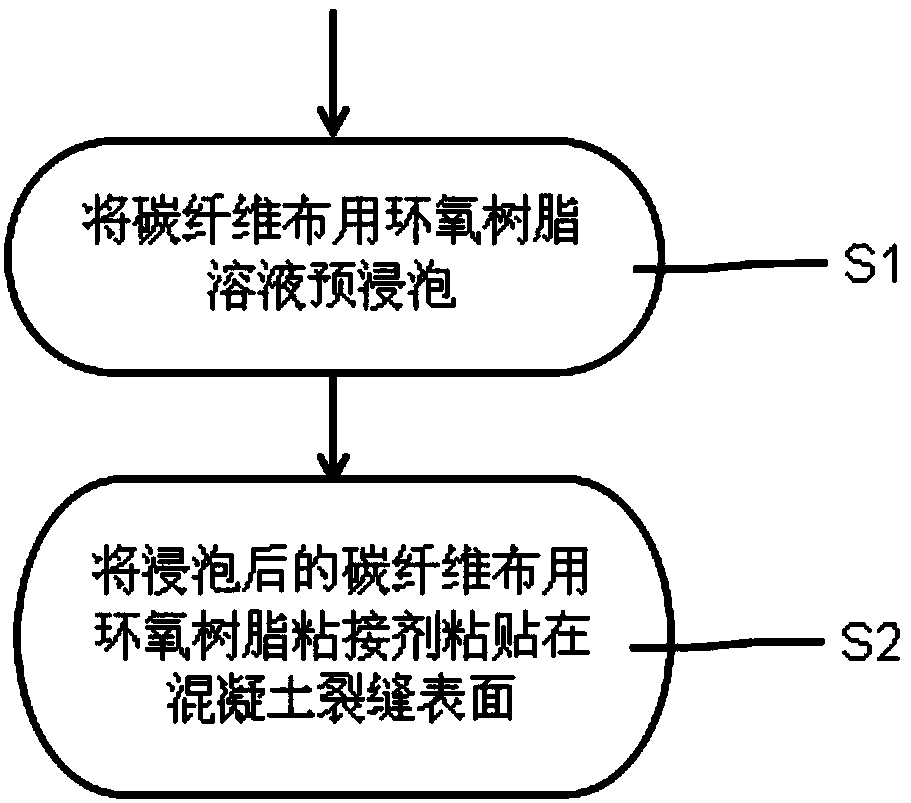

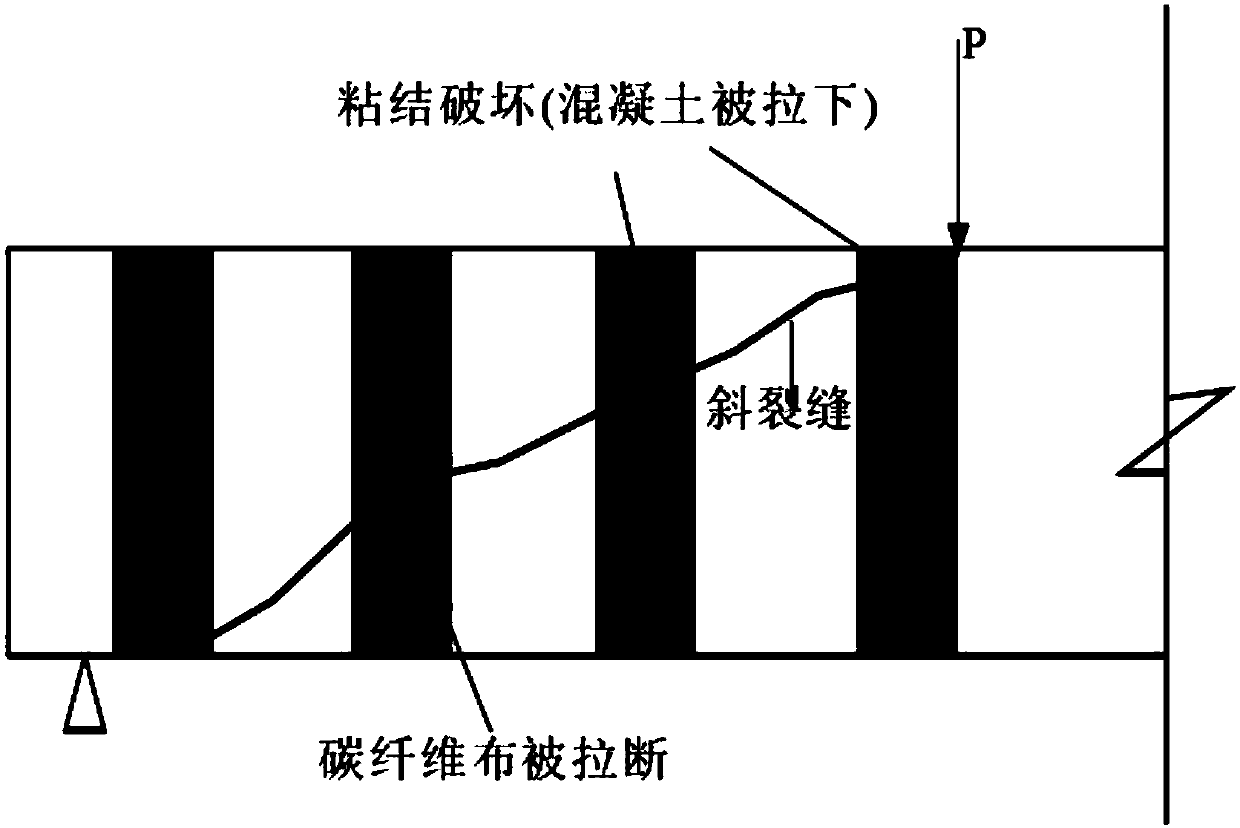

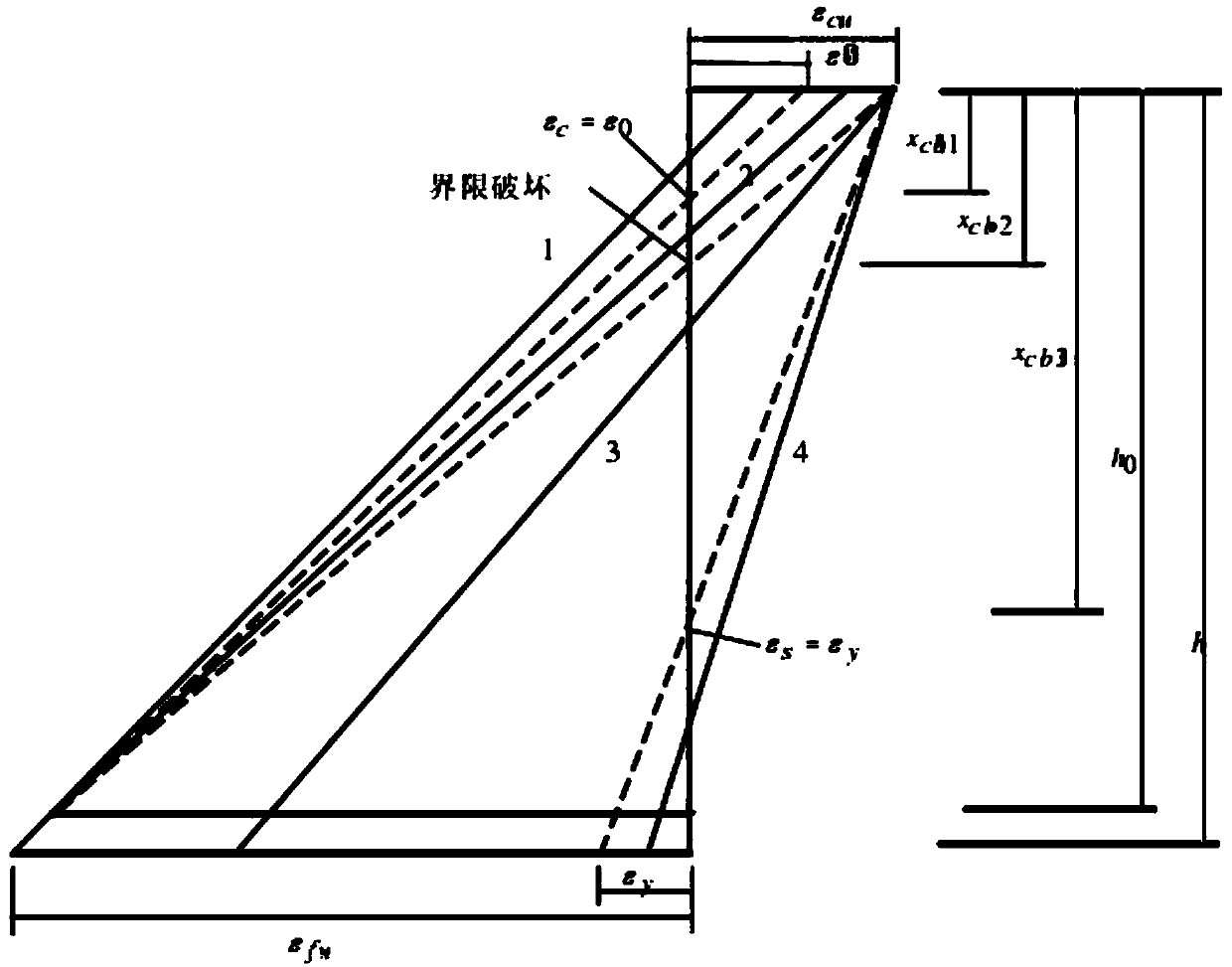

Carbon fiber structure reinforcement method

InactiveCN110219473AImprove axial tensile strengthHigh tensile strengthBuilding repairsEpoxyCarbon fibers

The invention belongs to the technical field of structural damage detection and reinforcement, and particularly relates to a carbon fiber structure reinforcement method. Before pasting a carbon fibercloth, the carbon fiber cloth is pre-soaked with an epoxy resin solution, the carbon fiber cloth after immersion is pasted on the surface of a concrete crack with an epoxy resin adhesive, and the carbon fiber cloth is pasted in the direction of the tension or in the direction perpendicular to the cracks. The carbon fiber structure reinforcement method solves the problem that in the prior art, thestrength, rigidity, stability and durability of a structure and a member cannot be well improved in the prior art, and has the beneficial technical effects of improving the strength, rigidity, crack resistance and elongation of the structure and being good in anti-seismic effect and better in reinforcement effect.

Owner:王伟

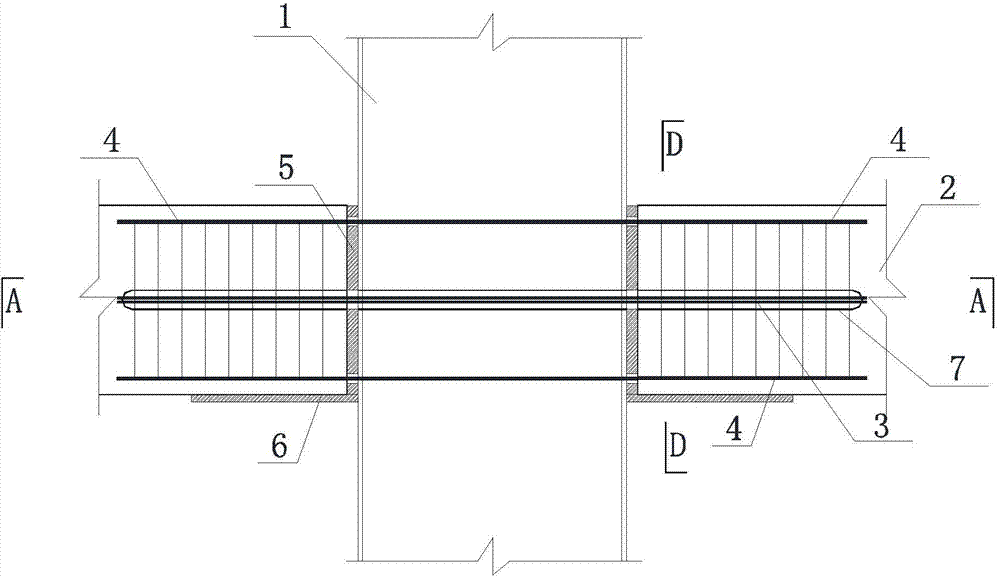

Node for connecting prefabricated concrete beam with rectangular steel tube concrete column through unbonded prestressed ribs

ActiveCN103938733AGuaranteed reliabilityReduce weakening effectBuilding constructionsConcrete beamsPre stress

The invention provides a node for connecting a prefabricated concrete beam with a rectangular steel tube concrete column through unbonded prestressed ribs, and belongs to the technical field of building structures. The node comprises the rectangular steel tube concrete column, the reinforced concrete beam, the unbonded prestressed ribs, a steel plate and channel steel. The rectangular steel tube concrete column and the reinforced concrete beam are prefabricated; the positions, corresponding to a section of the reinforced concrete beam, of the prefabricated reinforced concrete beam and of the rectangular steel tube concrete column are provided with hole channels; metal corrugated tubes are pre-buried in the hole channels; the section of the portion, connected with the reinforced concrete beam, of the rectangular steel tube concrete column is provided with the steel plate in a welded mode; the channel steel is welded to a rectangular steel tube; the unbonded prestressed ribs penetrate through the metal corrugated tubes and are tensioned so that the beam and the column can be connected into a whole. The construction speed is high, the onsite welding process is needless, reliability of node connection can be guaranteed, good anti-seismic performance is achieved, the node connection mode can be used for a side column node in a structure and can also be used for a middle column node and application prospects are wide.

Owner:北京中联浩科技服务有限公司

A kind of carbon fiber composite material automobile exhaust pipe tailpipe and manufacturing method thereof

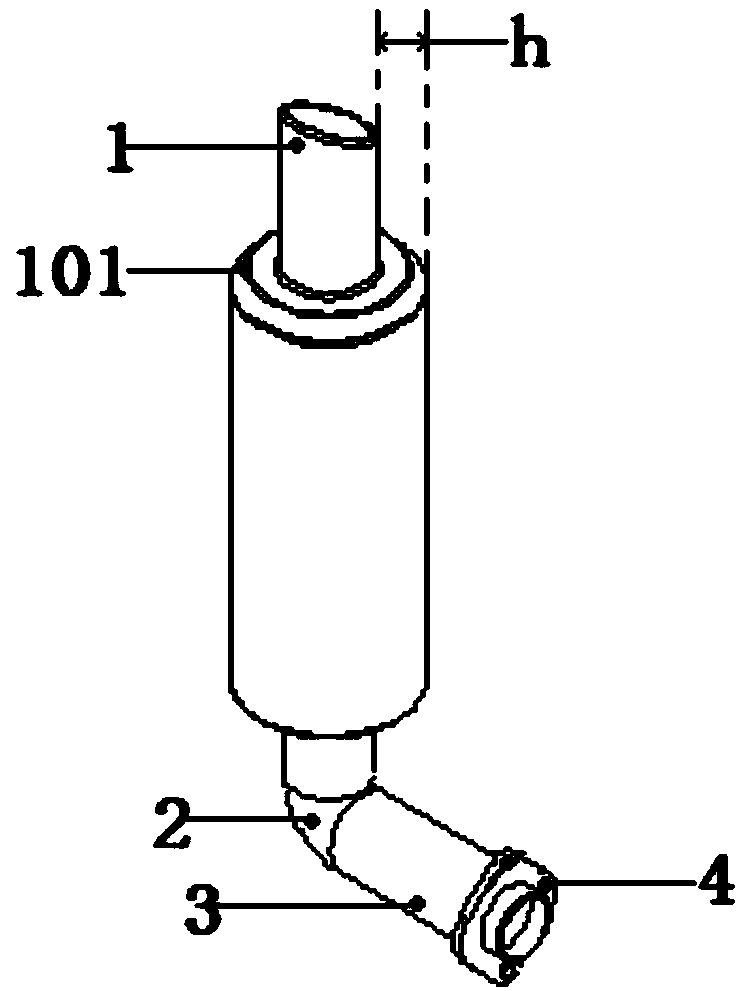

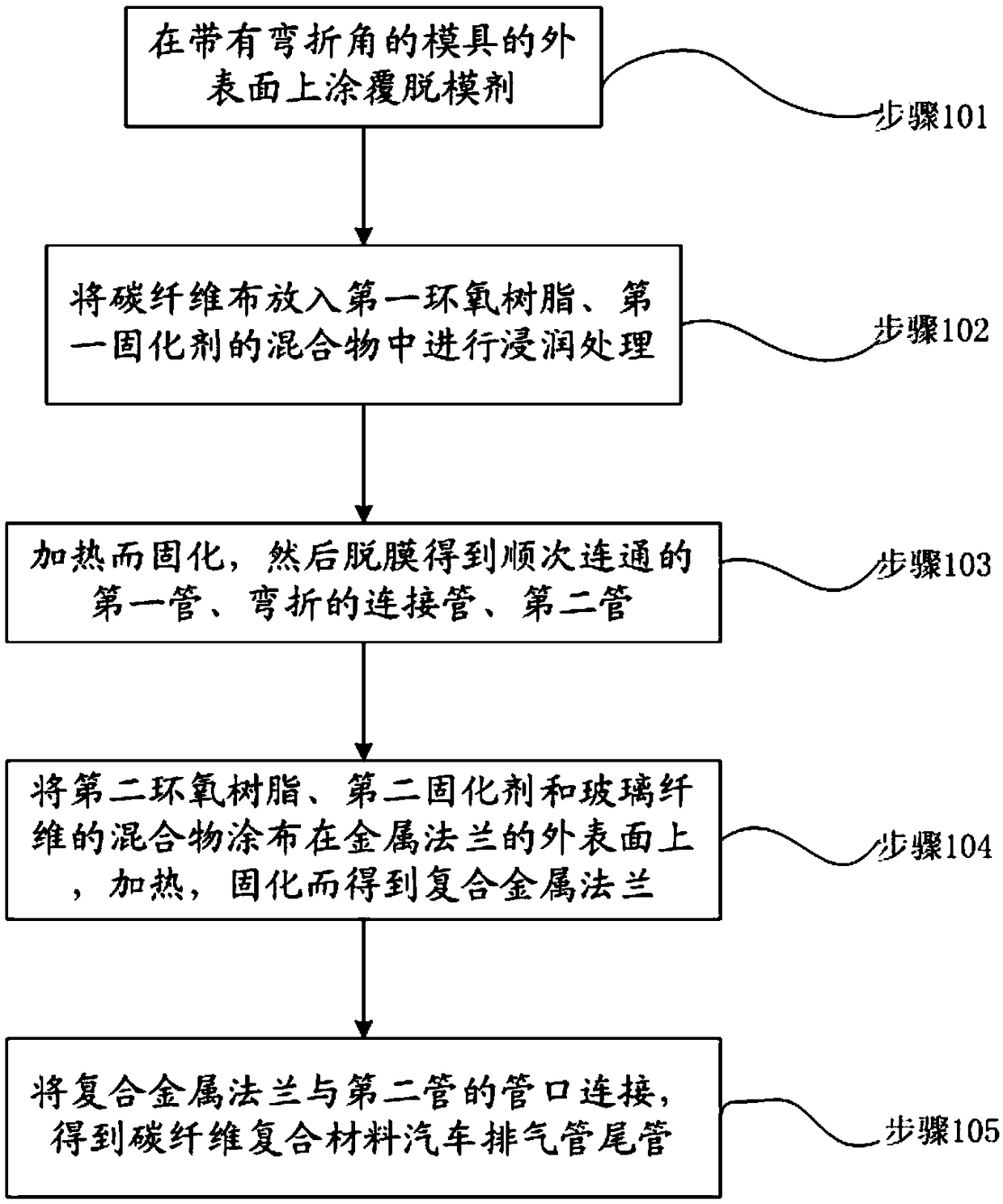

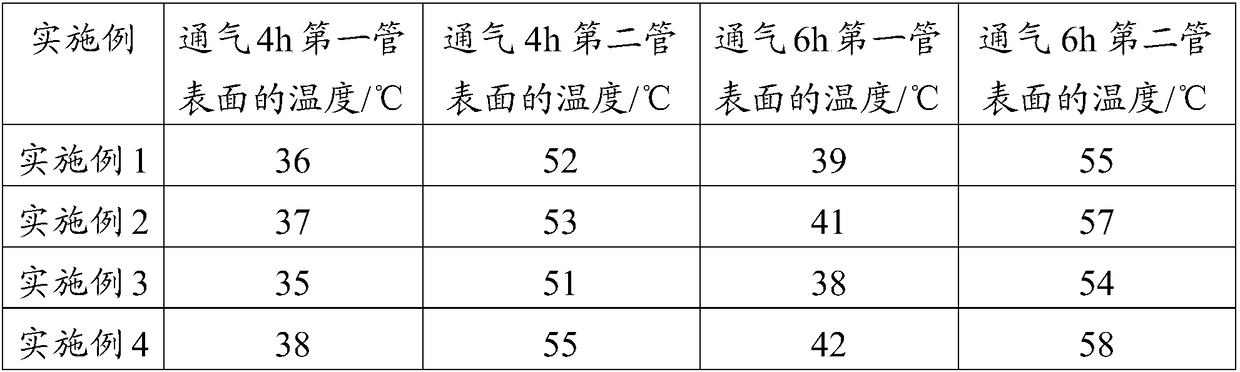

ActiveCN106499491BShock resistantSmall shock resistanceExhaust apparatusSilencing apparatusFiberShock resistance

The invention discloses a carbon fiber composite material automobile exhaust pipe tailpipe and a manufacturing method thereof, belonging to the field of automobile exhaust pipe tailpipes. The automobile exhaust pipe tailpipe comprises: a first pipe with an air outlet connected in sequence, a bent connecting pipe, a second pipe with an air inlet and a composite metal flange. The first pipe, the bent connecting pipe, and the second pipe are pipes formed of a composite material including carbon fiber, and the middle portion of the first pipe has a boss formed of a composite material including carbon fiber. By arranging the connecting pipe connecting the first pipe and the second pipe into a bent shape, the installation space of the automobile exhaust pipe tail pipe can be reduced, and the installation is convenient. By setting the middle part of the first pipe as a boss of carbon fiber composite material, the heat insulation effect of the automobile exhaust pipe is improved, and the normal operation of the automobile parts around the first pipe can be guaranteed. The carbon fiber composite automobile exhaust pipe tail pipe has the characteristics of shock resistance, corrosion resistance, light weight, good heat insulation effect, small installation space and the like.

Owner:CHERY AUTOMOBILE CO LTD

A trimming capacitor of gem medium

InactiveCN1963964AGreatly increased capacityGreatly improved pressure resistanceMechanically variable capacitorsEngineeringElectron

The disclosed gem-medium trimming capacitor comprises two ends with artificial gem as medium. Wherein, this invention has little loss and well capacity on anti-impact and anti-vibration for bad environment, has voltage endurance up to 1500VDC, while capacity up to 2.6 times to the air-medium capacitor, and fit to wide application in different vacations.

Owner:冯绍新

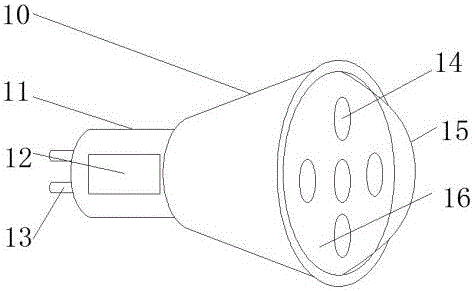

High-cooling-efficiency LED venture lamp

InactiveCN106016076AEasy to controlImprove lighting qualityPlanar light sourcesLighting support devicesGlass coverEngineering

The invention discloses an LED bold lamp with high heat dissipation efficiency, which comprises an aluminum alloy LED light box and an LED light cup. A fixing device is installed on the rear outer wall of the aluminum alloy LED light box, and a heat dissipation window is installed on the aluminum alloy LED light box. In addition, an LED lampshade is installed in front of the aluminum alloy LED light box, an LED lamp cover is installed at the center of the LED lamp cover, an angle adjustment device is installed on the left side of the LED lamp cover, and a steel plate is installed on the front outer wall of the LED lamp A glass cover, a base is installed on the left side of the LED lamp cup, a drive device is installed at the center of the base, a power pin is installed on the left side of the drive device, and an aluminum pin is installed on the right side of the LED lamp cup. The substrate, the LED wick is mounted on the aluminum substrate. The invention has lower requirements on the use environment and very fast response time, adopts multiple lamps for independent heat dissipation, reduces heat concentration, and improves heat dissipation efficiency.

Owner:吴建平

Unbonded prestress and ordinary steel bars connecting precast concrete beams with square and rectangular concrete-filled steel tube column composite joints

ActiveCN103924680BGuaranteed reliabilityReduce weakening effectBuilding constructionsSheet steelReinforced concrete

Owner:宝嘉智能科技(南通)有限公司

Optimal Design Method of Concrete Floor Slabs for Alleviating Earthquake Damage of Strong Beams and Weak Columns

InactiveCN105714968BImprove bearing capacityMake up for the weakened bearing capacityConstruction materialFloorsFloor slabStress level

The invention discloses a concrete floor optimized design method capable of relieving earthquake damages on strong beams and weak columns. The concrete floor optimized design method mainly comprises the following steps: calculating a floor thickness according to a conventional design method; calculating the location of a framework beam inflection point; determining a thin plate area range, thicknesses of plates within the thin plate area and a haunch plate area range; calculating concrete use difference within the thin plate area range, and distributing concrete towards the haunch plate area range to form a variable-section floor; and carrying out variable-section floor reinforcement design and thin plate area reinforcement design, thereby completing the concrete floor optimized design capable of relieving earthquake damages on strong beams and weak columns. According to the design method, the section height and the reinforcement quantity of adjacent floors in a framework beam hogging moment zone are reduced, hogging moment stress level when floor reinforcing steel bars participate in a framework beam is reduced, earthquake damages, caused by floor reinforcing effect, on the strong beams and weak columns are effectively relieved or almost avoided, and the anti-seismic design demand of the strong beams and weak columns are met.

Owner:郭猛

Composite joints of square rectangular concrete-filled steel tube columns in concrete beams connected by unbonded prestress and ordinary steel bars

ActiveCN103924677BGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressConcrete beams

The invention relates to a concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection and belongs to the technical field of building structures. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, unbonded prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are both cast in place. The connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam is provided with ducts in which metal bellows are embedded; the steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam and are provided with corresponding holes; the steel channels are welded on the square-rectangular concrete-filled steel tube column. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability can be guaranteed, seismic performance is good, a connection way of the joint is applicable to side column joints in structures and also applicable to middle column joints, and the joint has promising application prospect.

Owner:北京中联浩科技服务有限公司

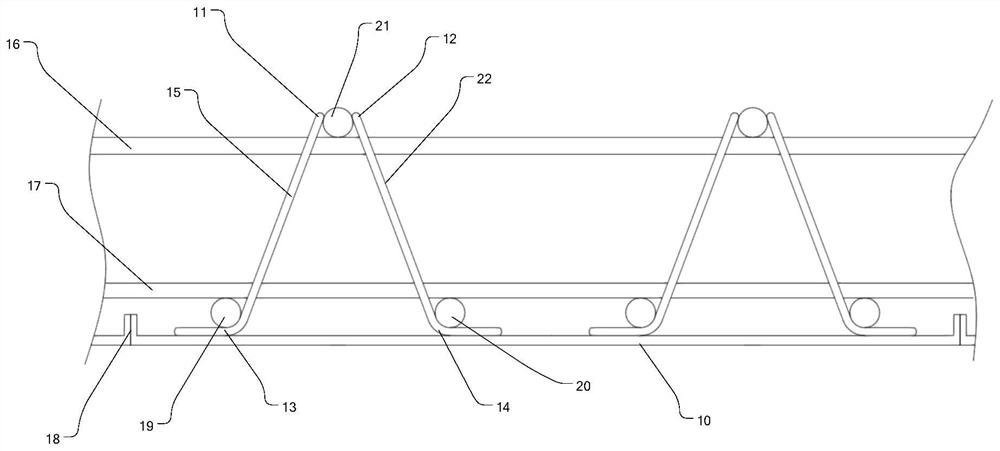

A reinforced truss floor deck and system

ActiveCN113530054BImprove on-site installation efficiencyQuality improvementFloorsBuilding reinforcementsArchitectural engineeringRebar

Owner:湖南中天杭萧钢构科技股份有限公司

Unbonded Prestressed Connected Concrete Beam Square Rectangular Steel Tube Concrete Column Joints

ActiveCN103924684BGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressingShock resistance

The invention relates to a rectangular concrete-filled steel tubular column node of an unbonded pre-stressing connecting concrete beam, and belongs to the technical field of building structures. The rectangular concrete-filled steel tubular column node comprises a rectangular concrete-filled steel tubular column, a reinforced concrete beam, unbonded pre-stressing tendons, a steel plate and channel steel. The rectangular concrete-filled steel tubular column and the reinforced concrete beam are both formed in a cast-in-situ mode and connected through the unbonded pre-stressing tendons; a hole way is reserved in the connecting cross section of the rectangular concrete-filled steel tubular column and the reinforced concrete beam, and a metal corrugated pipe is embedded in the hole way; the steel plate is welded to the connecting cross section of the rectangular concrete-filled steel tubular column and the reinforced concrete beam, and a corresponding hole is formed in the steel plate; the channel steel is welded to a rectangular steel tube. The rectangular concrete-filled steel tubular column node is high in construction speed, the site welding technology is not needed, the reliability of node connection can be guaranteed, the node has the good shock resistance, the node connecting mode can be used for side column nodes in the structure and can also be used for middle column nodes, and the application prospect is wide.

Owner:湖州市双林工业园区开发有限公司

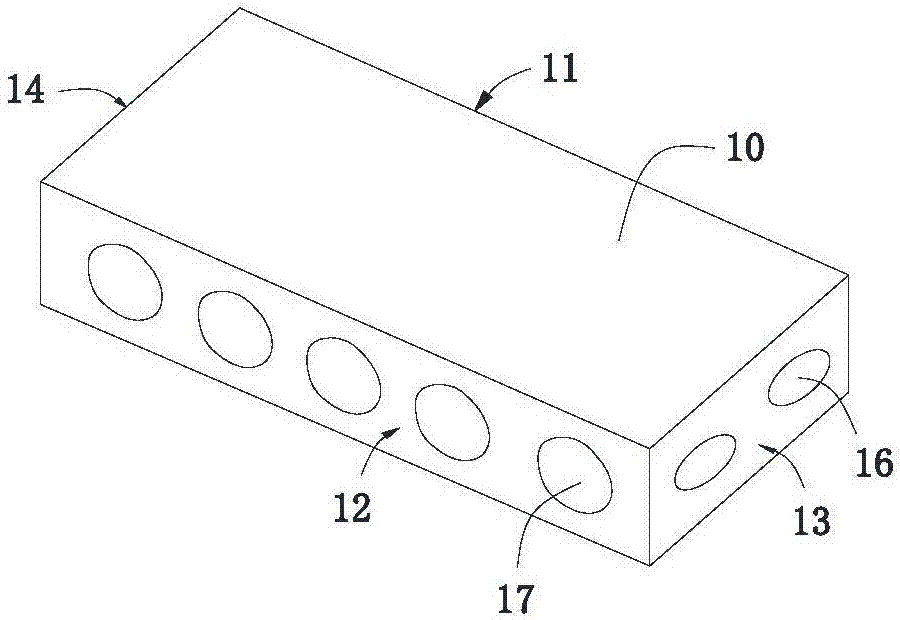

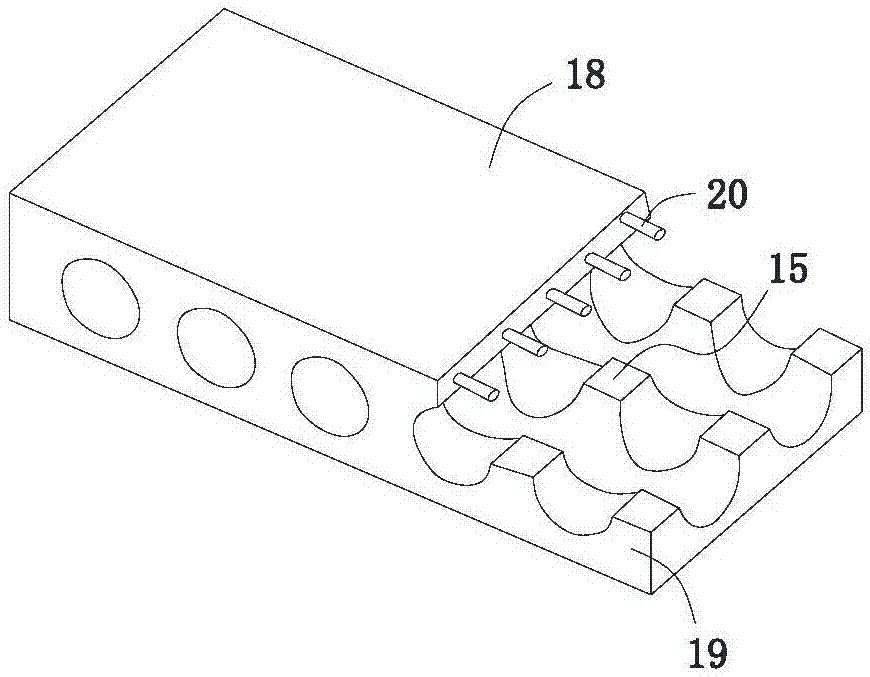

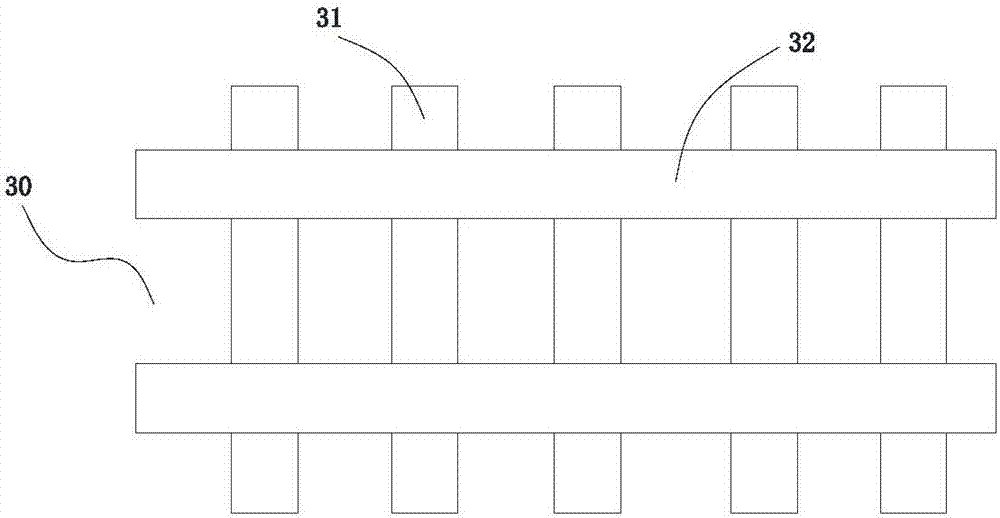

Two-way cavity reinforced concrete plate and manufacturing method thereof

PendingCN107060172AReduce dosageReduce thicknessFloorsHeat proofingReinforced concreteMesh reinforcement

The invention provides a two-way cavity reinforced concrete plate and a manufacturing method thereof and belongs to the field of building engineering. The two-way cavity reinforced concrete plate comprises a plate main body and two steel bar nets. The plate main body comprises a first width side face, a second width side face, a first length side face and a second length side face, wherein the first width side face and the second width side face are arranged oppositely, and the first length side face and the second length side face are arranged oppositely. A plurality of longitudinal hole channels and a plurality of transverse hole channels are formed in the plate main body. Two ports of each longitudinal hole channel are located on the first length side face and the second length side face correspondingly. Two ports of each transverse hole channel are located on the first width side face and the second width side face correspondingly. The multiple longitudinal hole channels and the multiple transverse hole channels communicate at intersections and are located between the two steel bar nets. The two-way cavity reinforced concrete plate has the advantages of two-way force bearing, hollow plate web, large span, fabricated construction, good heat preservation, heat insulation and sound insulation properties and the like.

Owner:CHINA AEROSPACE CONSTR GROUP

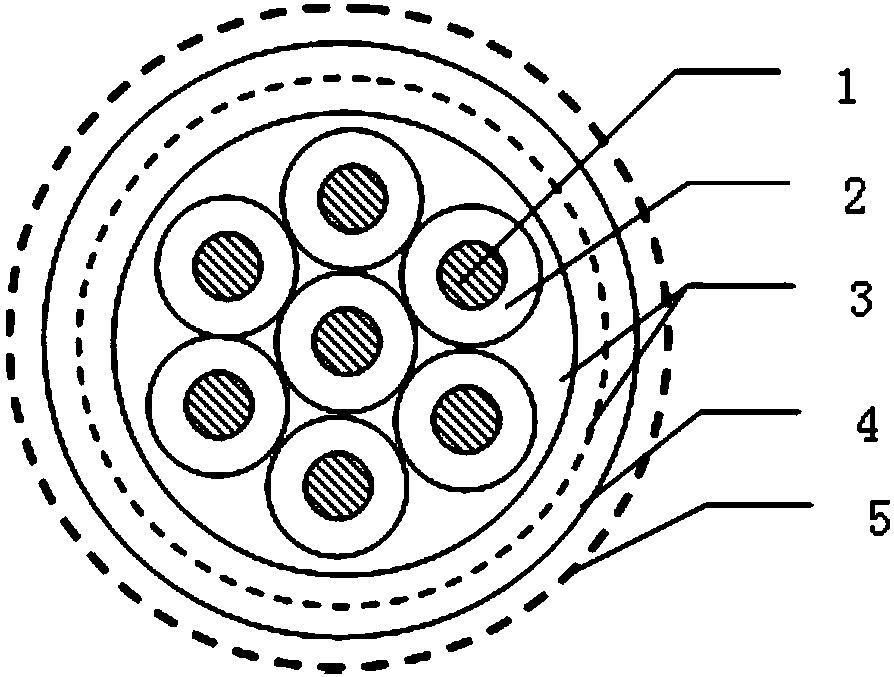

Anti-radiation and high-wear-resistance flexible cable

InactiveCN108597671AImprove conductivityImprove thermal conductivityExtensible conductorsExtensible conductor cablesYarnElectrical conductor

The invention discloses an anti-radiation and high-wear-resistance flexible cable, which consists of a conductor, an insulating layer, a composite main shield, a wrapping layer and a sheath layer frominside to outside, wherein the conductor is formed by stranding multiple strands of silver-coated annealed copper wires; the insulating layer is made of a crosslinked ethylene-tetrafluoroethylene copolymer; the composite main shield is formed by twisting an aluminum-plastic composite thin film and a silver-coated annealed copper wire; the wrapping layer is formed by wrapping a layer of halogen-free flame-retardant high-temperature-resistant woven belt; and the sheath layer is made of KEVLAR aramid yarn. The anti-radiation and high-wear-resistance flexible cable can meet the requirement for electrical property and also can meet high-temperature resistance, small size, light weight, flame retardancy, high wear resistance and chemical stability. The cable can keep the specific flexibility and high dielectric strength in extremely complicated and severe environments with various rays and ultraviolet radiations in the aerospace field.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

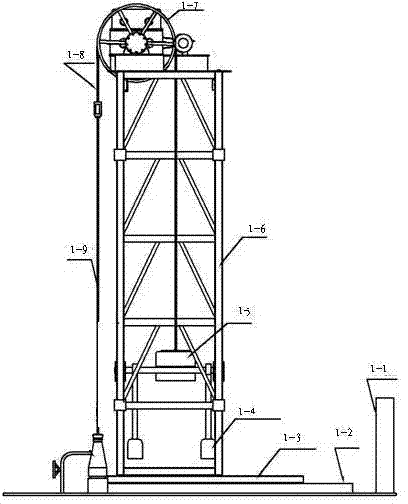

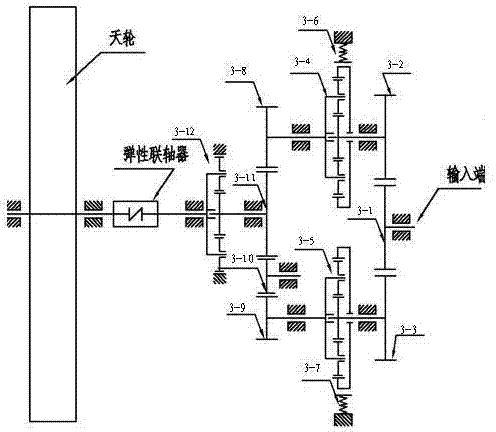

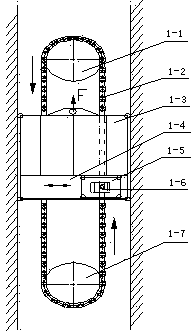

Novel vertical mechanical reversing energy-saving pumping unit

ActiveCN103216216BConvenient well workoverLess actual stroke lossToothed gearingsFluid removalStored energyGear drive

The invention relates to a novel vertical mechanical reversing energy-saving pumping unit. The novel vertical mechanical reversing energy-saving pumping unit is characterized in that a transmission system adopts a mechanical reversing, two-way gear drive and oil-immersed lubrication fully-enclosed reduction gearbox for realizing the positive and negative rotation of a head sheave of the pumping unit, to ensure the immense inertia of a pumping rod and a counterweight to decelerate, buffer until stop before the pumping unit runs to an upper dead point or a lower dead point, a crank buffer device is arranged so that the impact energy is smoothly absorbed and stored, the stored energy is released after passing through the upper dead point and the lower dead point, and a motor is started at an upper dead point or a lower dead point under the conditions of basically smooth input speed and torque. Through the adoption of mechanical reversing and closed oil-immersed lubrication, the adaptability of the pumping unit to the harsh environment is higher; as the motor runs in the same direction all the time, a complex electric control system is not provided, the reliability is high, and the servicing, the maintenance and the repair are simple; and the equipment is controlled to run by a PLC (programmable logic controller), and importantly, the system adopts a two-way backup, and therefore, both the reliability and the stability of the pumping unit are enhanced.

Owner:常州新槃威智能科技有限公司

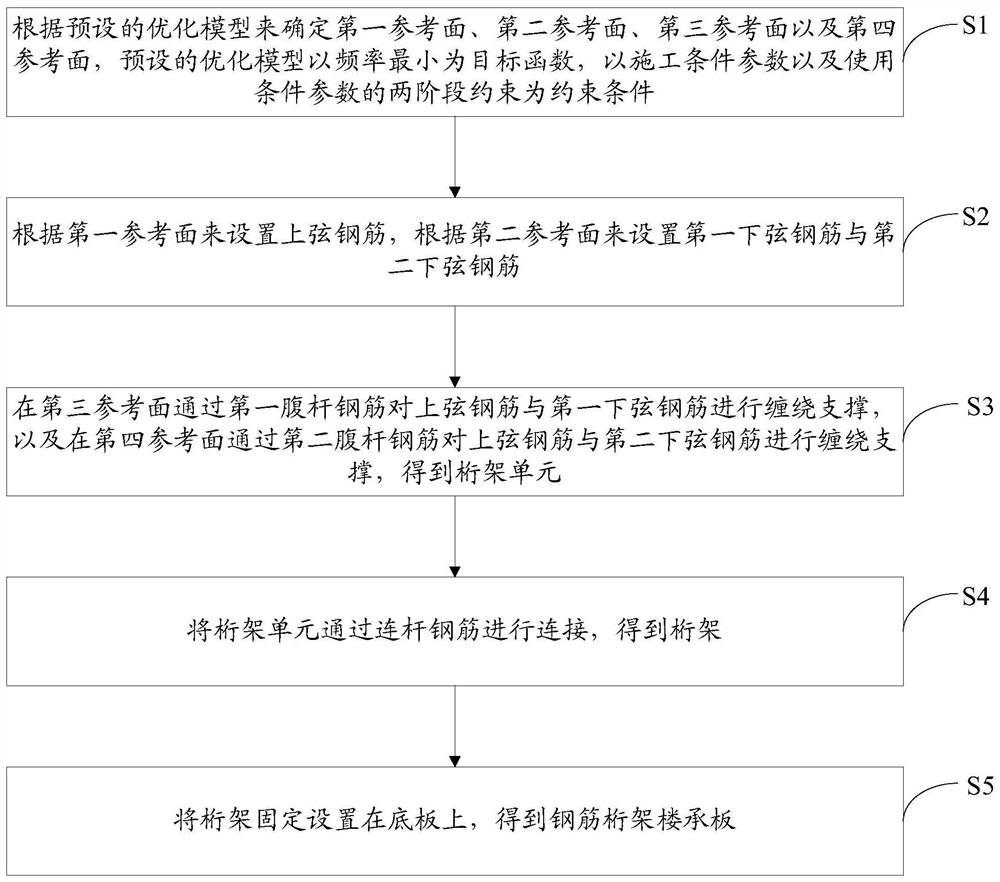

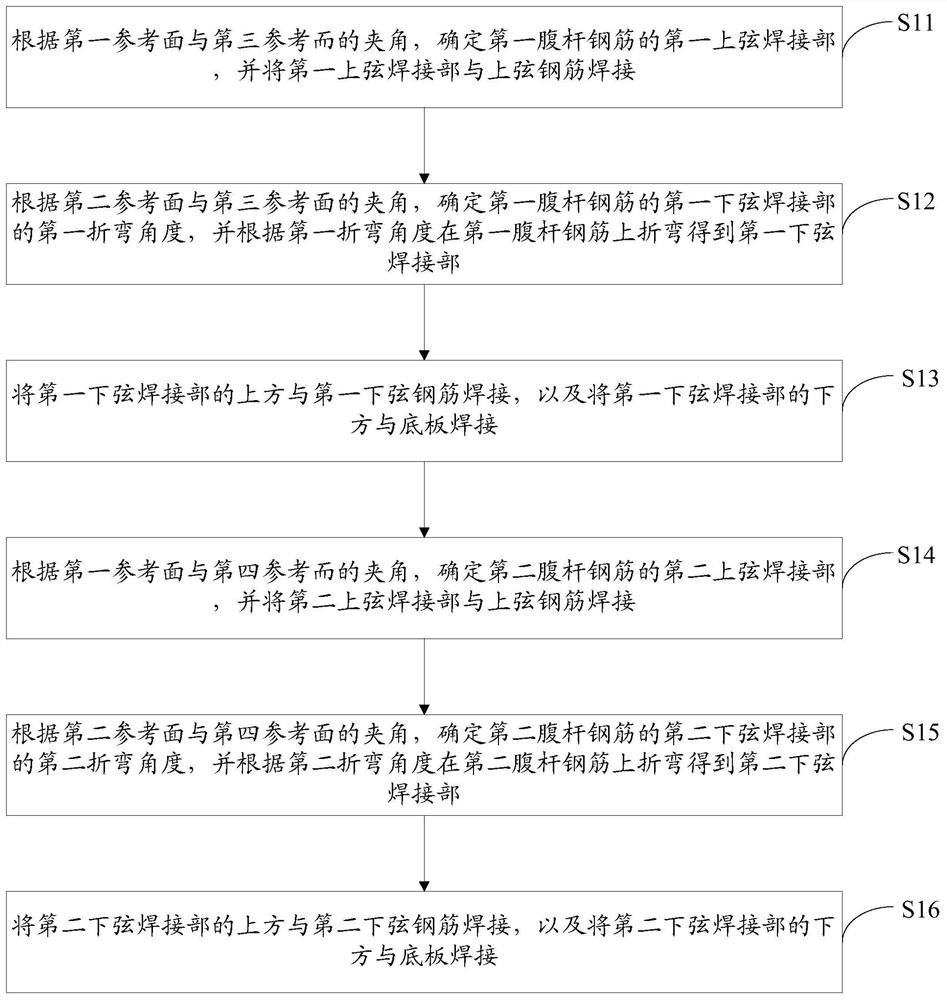

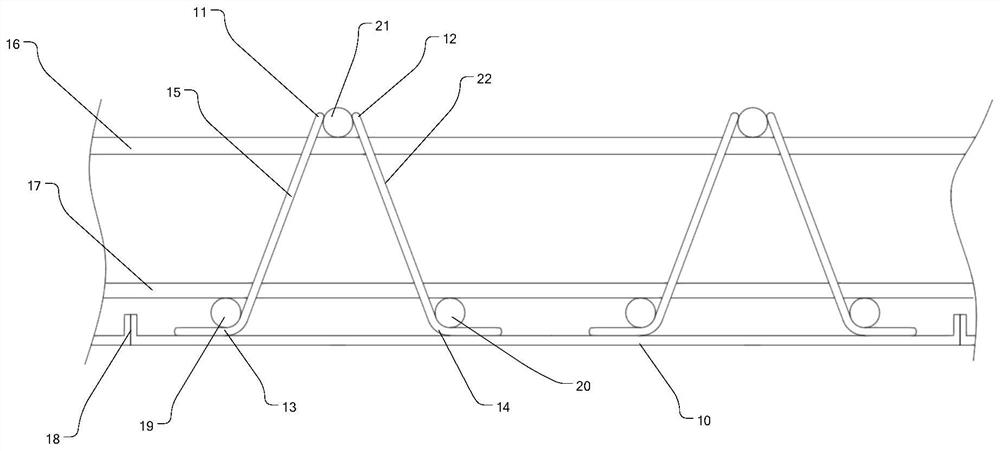

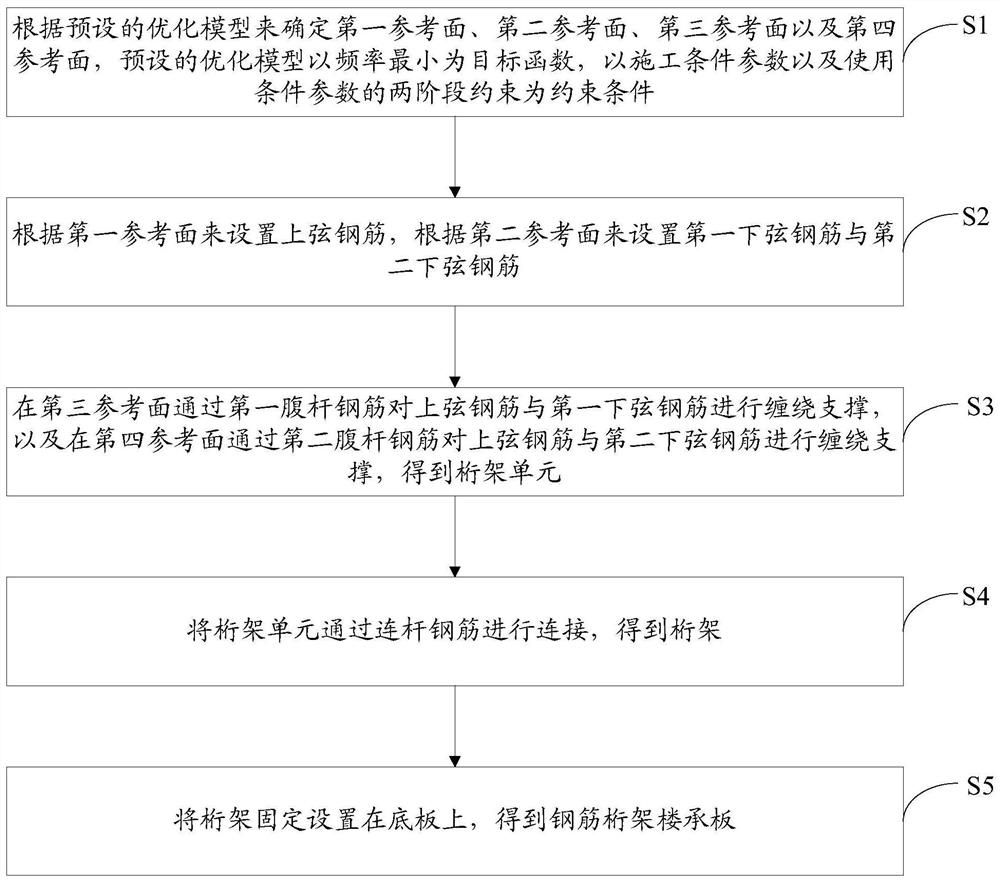

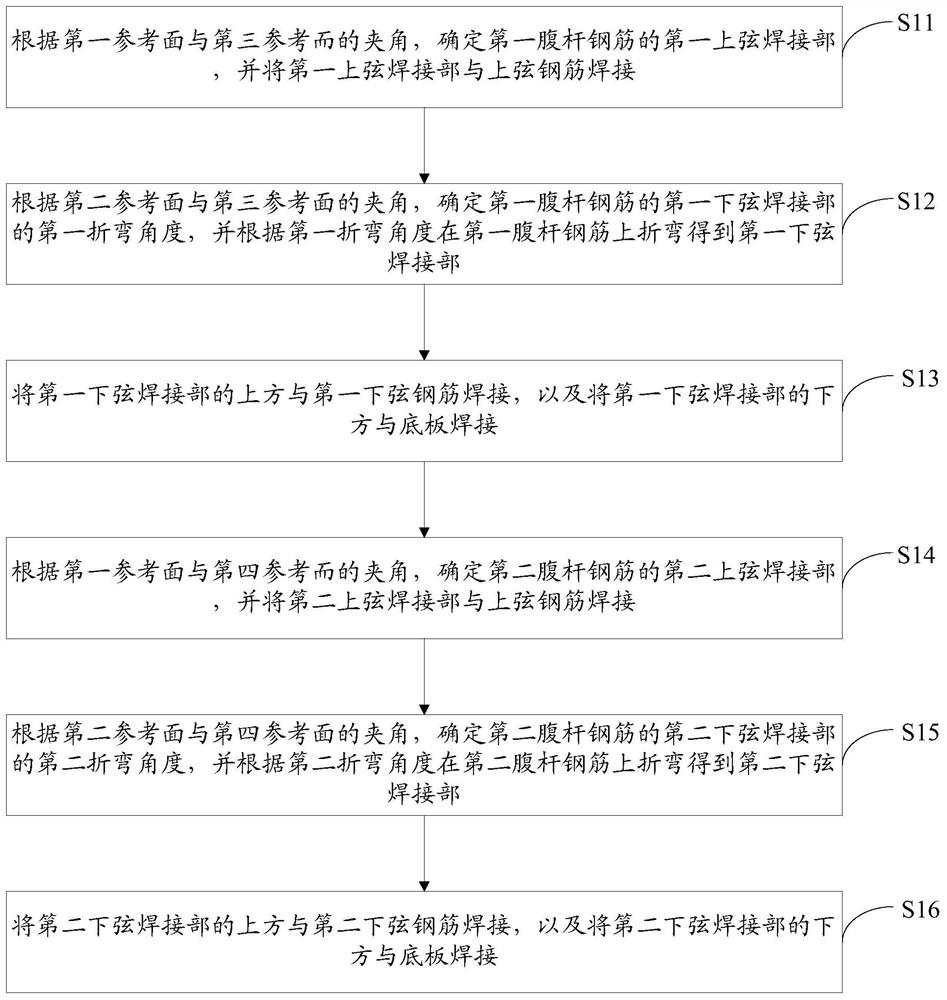

Steel bar truss floor support plate and system

ActiveCN113530054AImprove on-site installation efficiencyQuality improvementFloorsBuilding reinforcementsArchitectural engineeringRebar

The invention provides a steel bar truss floor support plate and a production method. The steel bar truss floor support plate is characterized in that the steel bar truss floor support plate comprises a truss and a bottom plate, and the truss is fixedly arranged on the bottom plate; the truss comprises a plurality of truss units and connecting rod reinforcing steel bars used for connecting the truss units, each truss unit comprises an upper chord reinforcing steel bar arranged on a first reference plane, a first lower chord reinforcing steel bar and a second lower chord reinforcing steel bar arranged on a second reference plane, a first web member reinforcing steel bar arranged on a third reference plane, and a second web member reinforcing steel bar arranged on a fourth reference plane; and the first reference plane, the second reference plane, the third reference plane and the fourth reference plane are determined according to a preset optimization model. The steel bar truss floor support plate can be machined and manufactured in advance before leaving a factory, the field installation workload is reduced, and the field installation efficiency of the steel bar truss floor support plate is improved; and meanwhile, the anti-seismic performance is high, and the quality of a corresponding building is improved.

Owner:湖南中天杭萧钢构科技股份有限公司

Unbonded prestressed joints of precast concrete beams with square rectangular concrete filled steel tube columns

ActiveCN103938733BGuaranteed reliabilityReduce weakening effectBuilding constructionsSheet steelConcrete beams

The invention provides a node for connecting a prefabricated concrete beam with a rectangular steel tube concrete column through unbonded prestressed ribs, and belongs to the technical field of building structures. The node comprises the rectangular steel tube concrete column, the reinforced concrete beam, the unbonded prestressed ribs, a steel plate and channel steel. The rectangular steel tube concrete column and the reinforced concrete beam are prefabricated; the positions, corresponding to a section of the reinforced concrete beam, of the prefabricated reinforced concrete beam and of the rectangular steel tube concrete column are provided with hole channels; metal corrugated tubes are pre-buried in the hole channels; the section of the portion, connected with the reinforced concrete beam, of the rectangular steel tube concrete column is provided with the steel plate in a welded mode; the channel steel is welded to a rectangular steel tube; the unbonded prestressed ribs penetrate through the metal corrugated tubes and are tensioned so that the beam and the column can be connected into a whole. The construction speed is high, the onsite welding process is needless, reliability of node connection can be guaranteed, good anti-seismic performance is achieved, the node connection mode can be used for a side column node in a structure and can also be used for a middle column node and application prospects are wide.

Owner:北京中联浩科技服务有限公司

Folding airport emergency emergency construction composite material composite road panel and its manufacturing method

ActiveCN109235177BHigh molecular weightImprove tensile strength at breakHelicopter landing platformSynthetic resin layered productsEpoxyFiber

The invention provides a foldable airport emergency construction composite material composite road panel and a manufacturing method thereof. The composite material composite road panel is composed of a veneer and a connecting cloth; the veneer is a rectangular board, which is laid side by side on the upper and lower sides of the connecting cloth, and the veneers on the upper and lower sides are arranged symmetrically; between the veneer and the connecting cloth Bonded together by epoxy resin; each veneer is made of composite fiber materials, such as glass fiber cloth, ultra-high molecular weight polyethylene fiber cloth and carbon fiber cloth. The material of the combined road panel is light, the density is only between 1.15 and 1.17, and the density is less than one-sixth of the ordinary steel plate. High bending strength of the panel > 280MPa, strong impact toughness > 240K j / m 2 , its strength can meet the carrying capacity of three generations of fighter jets and various types of armed helicopters. This panel has the advantages of high bending strength, strong impact resistance, light material, large area, good aging resistance and durability, easy repair and paving, time-saving and efficient repair, and can be reused.

Owner:NINGBO DACHENG ADVANCED MATERIAL +1

Unbonded prestressed joints of precast concrete beams with circular concrete-filled steel tube columns

ActiveCN103938729BGuaranteed reliabilityReduce weakening effectBuilding constructionsRebarPrecast concrete

Owner:南京易蔚均科技有限公司

Device of titanium metal wire net cage compounded with titanium metal wire engineering bone and preparation method thereof

ActiveCN102085123BLightweight yet strongExuberant formationBone implantCoatingsTitanium metalInvestment material

The invention provides a device of a titanium metal wire net cage compounded with a titanium metal wire engineering bone and a preparation method thereof, and the device of the titanium metal wire net cage compounded with the titanium metal wire engineering bone comprises a piston type titanium metal wire net cage and a titanium metal wire engineering bone composite filled in the piston type titanium metal wire net cage; and the preparation method comprises the following steps: winding titanium metal wire non-woven fabric on the outer wall of a titanium metal cage body and sintering for preparing a titanium metal wire net cage body, then coating hydroxyapatite on the inner surface and the outer surface of the cage body, and then placing two piston type cap-shaped bodies in an inner cavityof the metal cage body for getting the piston type titanium metal wire net cage; and further uniformly mixing titanium metal wires, a morselized bone, a binding material and auxiliary materials, and filling into the piston type titanium metal wire net cage. The device has good elastic modulus coordination and high strength, and can be used in the field of bone surgery.

Owner:HARBIN MEDICAL UNIVERSITY

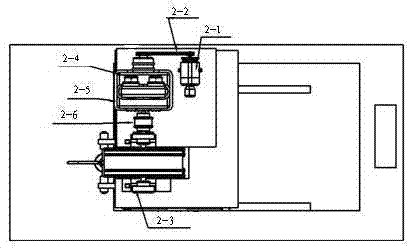

Mechanical reversing speed reducer and vertical type pumping unit

ActiveCN103244620BSolution to short lifeReduce the temperatureToothed gearingsFluid removalFailure rateReduction drive

The invention relates to a mechanical reversing speed reducer and a vertical type pumping unit. The mechanical reversing speed reducer is applicable to various reversing-driving-needing fields of petroleum, mines, ports and the like. A reversing mechanism is characterized in that a motor inputs power into a speed reduction gearbox in which two sets of parallel planetary gear trains are arranged, each of the two sets of the planetary gear trains is shifted through a hydraulic braking device to enable the planetary gear trains to alternately operate in a free state and a speed reduction driving state, the back of the two sets of the planetary gear trains is provided with a merging gear set to merge the power and drive a second stage speed reduction planetary gear train to finally transmit the power to a head sheave, the working condition of the two sets of the parallel planetary gear trains is shifted alternately through the hydraulic braking device, and the mechanical reversing operation of the head sheave is achieved. The reversing mechanism of the mechanical reversing speed reducer and the vertical type pumping unit is long in service life, low in failure rate, stable in operation, highly efficient, energy-saving and compact in structure, and can adjust different travel speed according to specific working conditions so that the oil extraction of an oil well can reach the best economic benefit.

Owner:常州新槃威智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com