Anti-radiation and high-wear-resistance flexible cable

A flexible cable and anti-radiation technology, applied in the direction of insulated cables, extensible conductor cables, cables, etc., can solve high temperature, flame retardancy, unsatisfactory strength and flexibility, unprotected cables, large weight and volume and other problems, to achieve the effect of improving the ability of strong electromagnetic wave interference, small specific gravity, and large volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

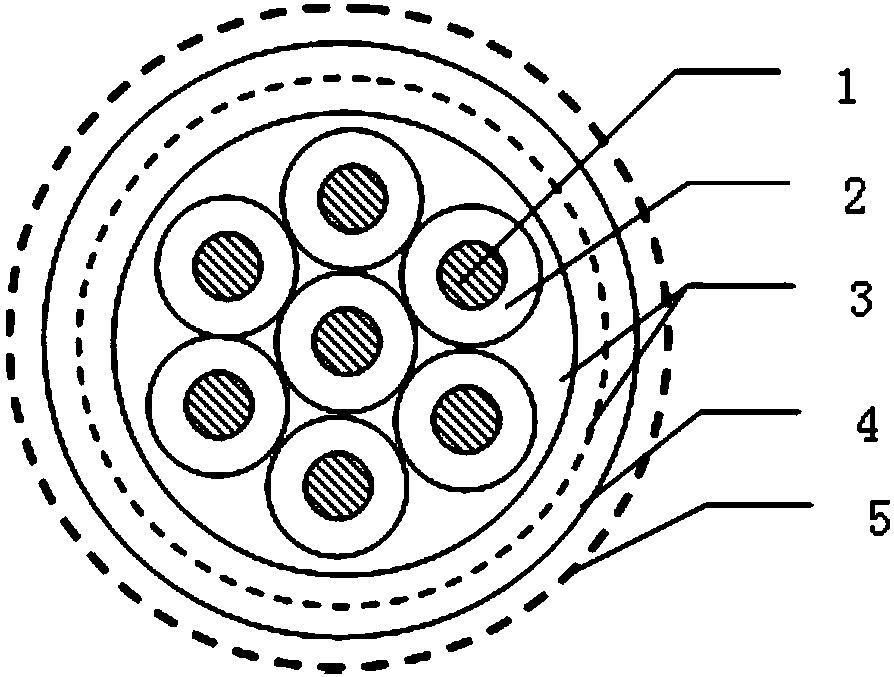

[0018] Such as figure 1 Shown is a preferred embodiment of the present invention, a radiation-proof, highly wear-resistant flexible cable, comprising a conductor 1 twisted with multiple silver-plated annealed copper wires, an insulating layer 2 is arranged outside the conductor 1, and the conductor 1 It forms an insulated single wire with the insulating layer 2, and twists the insulated single wire to form a cable core. There is a composite overall shield 3 outside the cable core, a wrapping layer 4 is set outside the composite overall shield 3, and a sheath is set outside the wrapping layer 4. Layer 5.

[0019] Among them, the structure of conductor 1 is 19 / 0.12mm; the insulating layer 2 is made of cross-linked ethylene-tetrafluoroethylene copolymer material extruded by extruded tube type processing method, and processed by irradiation, and its nominal thickness is 0.15mm ; Composite overall shielding 3 is wrapped with aluminum-plastic composite film on the inner layer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com