Electric transmission system of low-floor light rail vehicle

An electric transmission and low-floor technology, which is applied in the field of vehicle electric transmission system, can solve the problems that the electric transmission system cannot adapt to low-floor light rail cars, etc., and achieve the effect of high reliability, high protection level and powerful functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

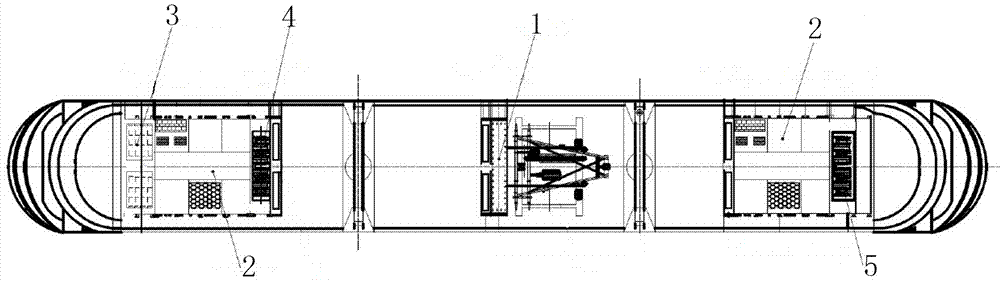

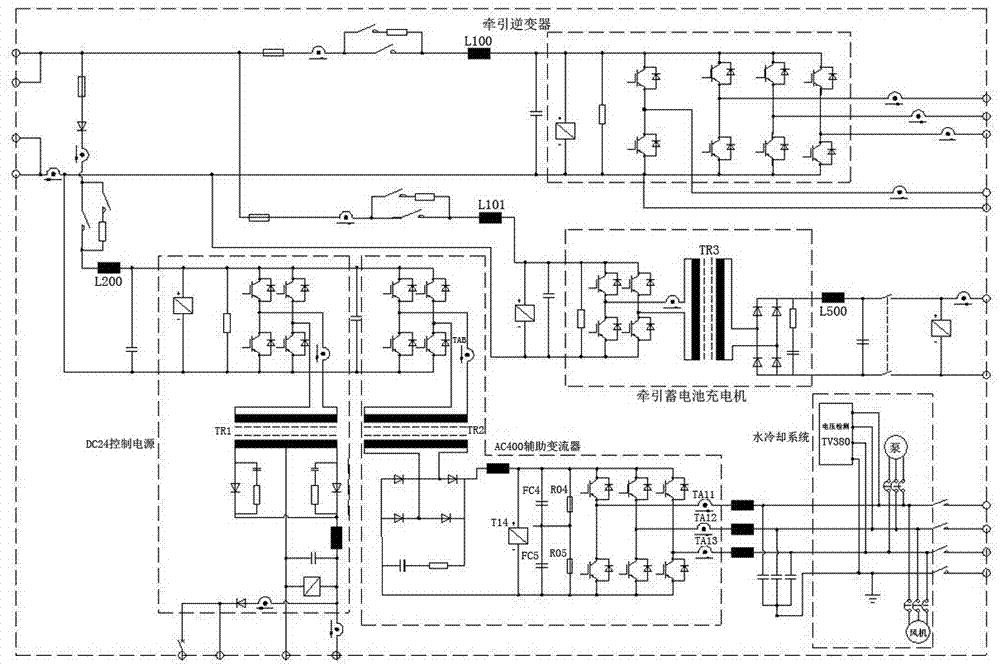

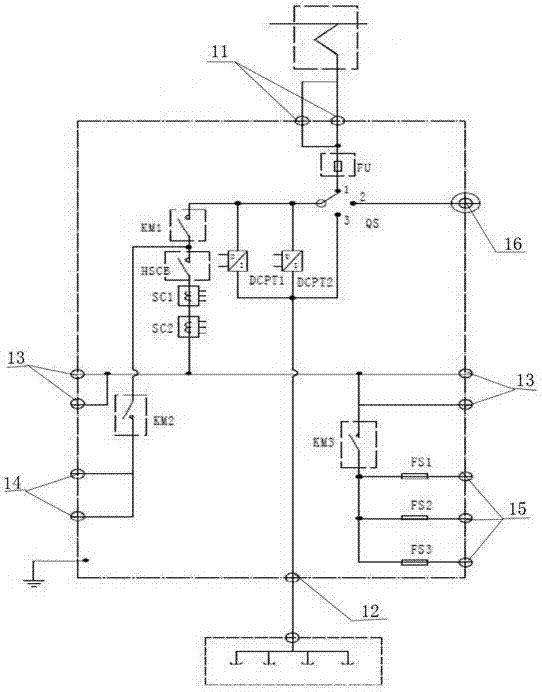

[0010] The electric drive system of a low-floor light rail vehicle includes a high-voltage box 1, two traction auxiliary converters 2, a braking resistor box 3, a 24V battery 4 and a traction battery 5; the high-voltage box 1 includes a main fuse, an isolation switch, high-speed circuit breaker; traction auxiliary converter 2 includes traction inverter, smoothing reactor, DC24V control power supply, AC400V auxiliary inverter and traction battery charger, of which DC24V control power supply, AC400V auxiliary inverter and traction The transformer included in the battery charger is a high-frequency transformer; the high-voltage box 1, the traction auxiliary converter 2 and the braking resistor box 3 are box-type designs with a height not exceeding 530mm; the high-voltage box 1 is set in the middle of the roof, and the two The traction auxiliary converter 2 is placed at both ends of the roof, the 24V battery 4 and the traction battery 5 are placed at both ends of the roof, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com