Structure of thermal fin with high heat conductivity and its manufacturing method

A technology with high thermal conductivity and heat sink, applied in semiconductor devices, semiconductor/solid-state device components, electrical components, etc., it can solve the problems of limited thermal conduction efficiency, inability to meet the heat dissipation requirements of higher-speed central processing units, and high proportion of copper alloy heat sinks , to achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

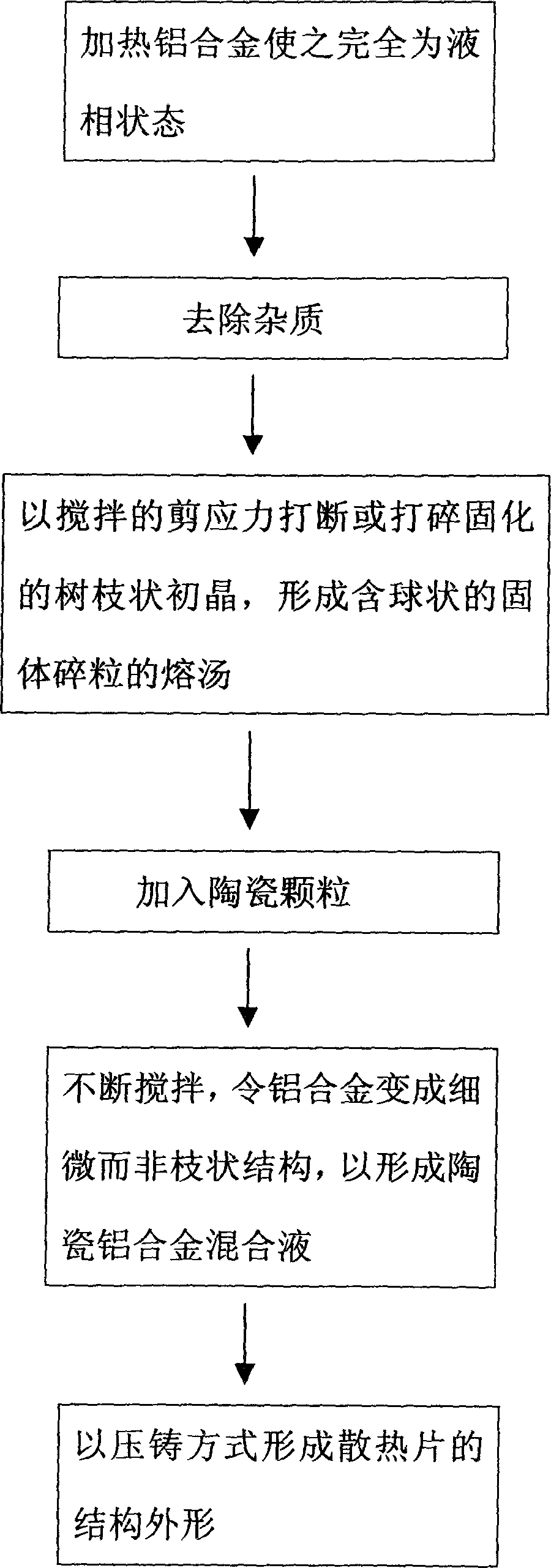

Method used

Image

Examples

Embodiment 1

[0019] The aluminum alloy adopts AlMgSi, and the composition of the aluminum alloy is:

[0020] Si

Fe

Cu

mn

Mg

Cr

Zn

Al

0.6

0.35

0.1

0.1

0.75

0.1

0.1

97.9

[0021] Silicon carbide accounts for 10% by weight of the overall heat sink, and the particle size of silicon carbide is 80 μm. The specific method is as follows:

[0022] 1. Heat the aluminum alloy to 660-720°C in a melting furnace, and make sure that the aluminum alloy is completely in a liquid state.

[0023] 2. Carry out slag removal work to remove impurities in aluminum alloy.

[0024] 3. Add ceramic particles.

[0025] 4. Stir the molten soup with a stirring rod at the solid-liquid phase temperature, and keep the temperature of the molten soup at 550-700°C.

[0026] 5. Use the robotic arm to scoop up the evenly stirred molten soup and inject it into the injection system of the die-casting equipment for injection and forming. Th...

Embodiment 2

[0029] The aluminum alloy adopts AlMgSi, and the composition of the aluminum alloy is the same as that in Example 1.

[0030] Silicon carbide accounts for 25% by weight of the overall heat sink, and the particle size of silicon carbide is 120 μm. The specific method is as follows:

[0031] 1. The melting furnace heats the aluminum alloy to 660-720°C, and confirms that the aluminum alloy is completely in a liquid state.

[0032] 2. Carry out slag removal work to remove impurities in aluminum alloy.

[0033] 3. Add ceramic particles.

[0034] 4. Stir the molten soup with a stirring rod at the solid-liquid phase temperature, and keep the temperature of the molten soup at 550-700°C.

[0035] 5. Use the robotic arm to scoop up the evenly stirred molten soup and inject it into the injection system of the die-casting equipment for injection and forming. The clamping force of the die-casting machine is 200-250ton, and the casting area pressure during injection is 150-250Kg / cm 2 ...

Embodiment 3

[0038] The aluminum alloy adopts AlMgSi, and the composition of the aluminum alloy is the same as that in Example 1.

[0039] Silicon carbide accounts for 60% by weight of the overall heat sink, and the particle size of silicon carbide is 320 μm. The specific method is as follows:

[0040] 1. The melting furnace heats the aluminum alloy to 700-760°C, and confirms that the aluminum alloy is completely in a liquid state.

[0041] 2. Carry out slag removal work to remove impurities in aluminum alloy.

[0042] 3. Add ceramic particles.

[0043] 4. Stir the molten soup with a stirring rod at the solid-liquid phase temperature, and keep the temperature of the molten soup at 590-630°C.

[0044] 5. Use the robotic arm to scoop up the evenly stirred molten soup and inject it into the injection system of the die-casting equipment for injection and forming. The clamping force of the die-casting machine is 200-250ton, and the casting area pressure during injection is 150-250Kg / cm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com