High-impact-toughness automotive frame steel belt and production method thereof

A technology of automobile beam steel and production method, applied in the field of strip steel, can solve the problems of affected welding performance and surface quality, unsuitability, high Si content of materials, and achieve low-cost and high-efficiency alloy cost control, good low-temperature impact toughness, and mechanical properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

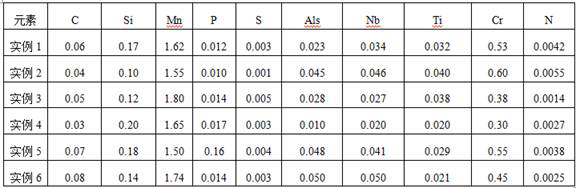

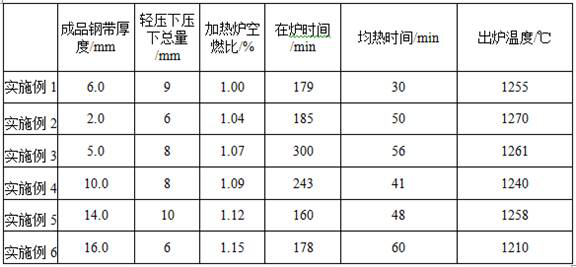

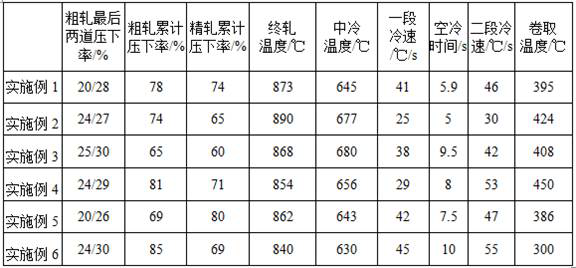

[0030] A high-impact-toughness automobile beam steel belt of the present invention, its chemical composition and its weight percentage are: C: 0.03%-0.08%, Si: 0.10%-0.20%, Mn: 1.50%-1.80%, P≤0.017%, S≤0.005%, Als:0.010%-0.050%, Ti:0.020%-0.040%, Nb:0.020%-0.050%, Cr:0.30%-0.60%, N≤0.0055%, others are Fe and unavoidable residues element. The production method includes continuous casting, slab heating, rolling and cooling production processes.

[0031] In the continuous casting process, the temperature of molten steel entering the tundish is controlled at 1510-1535°C, the degree of superheat ΔT=10-30°C, the cast slab adopts a constant casting speed of 0.8-1.4m / min, and the liquid level fluctuation is controlled within ±5mm. Dynamic light reduction is adopted at the end of the solidification of the slab, and the total reduction is ≥6mm. During the pouring process, the casting is protected by argon gas to prevent the outside air from entering. Maintain a constant casting speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com