Method for manufacturing radiator and radiator

A manufacturing method and heat sink technology, applied in the manufacture of heat sinks and the field of heat sinks, can solve the problems of large volume and weight of the whole product, high heat generation, difficulty in promoting the miniaturization and lightweight design of high-power electronic products, and achieve Improve the convection and radiation cooling capacity, increase the cooling area, and realize the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

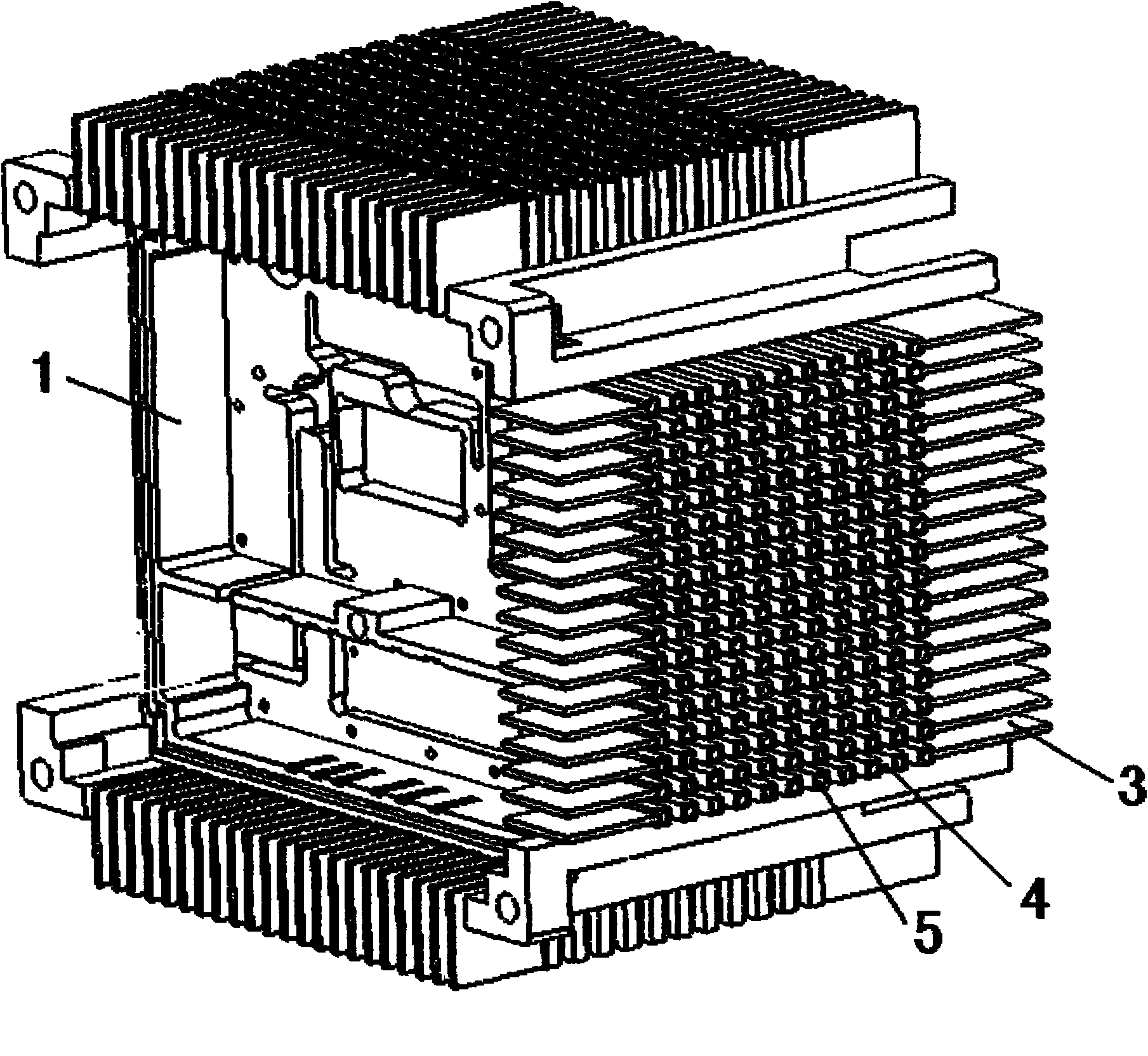

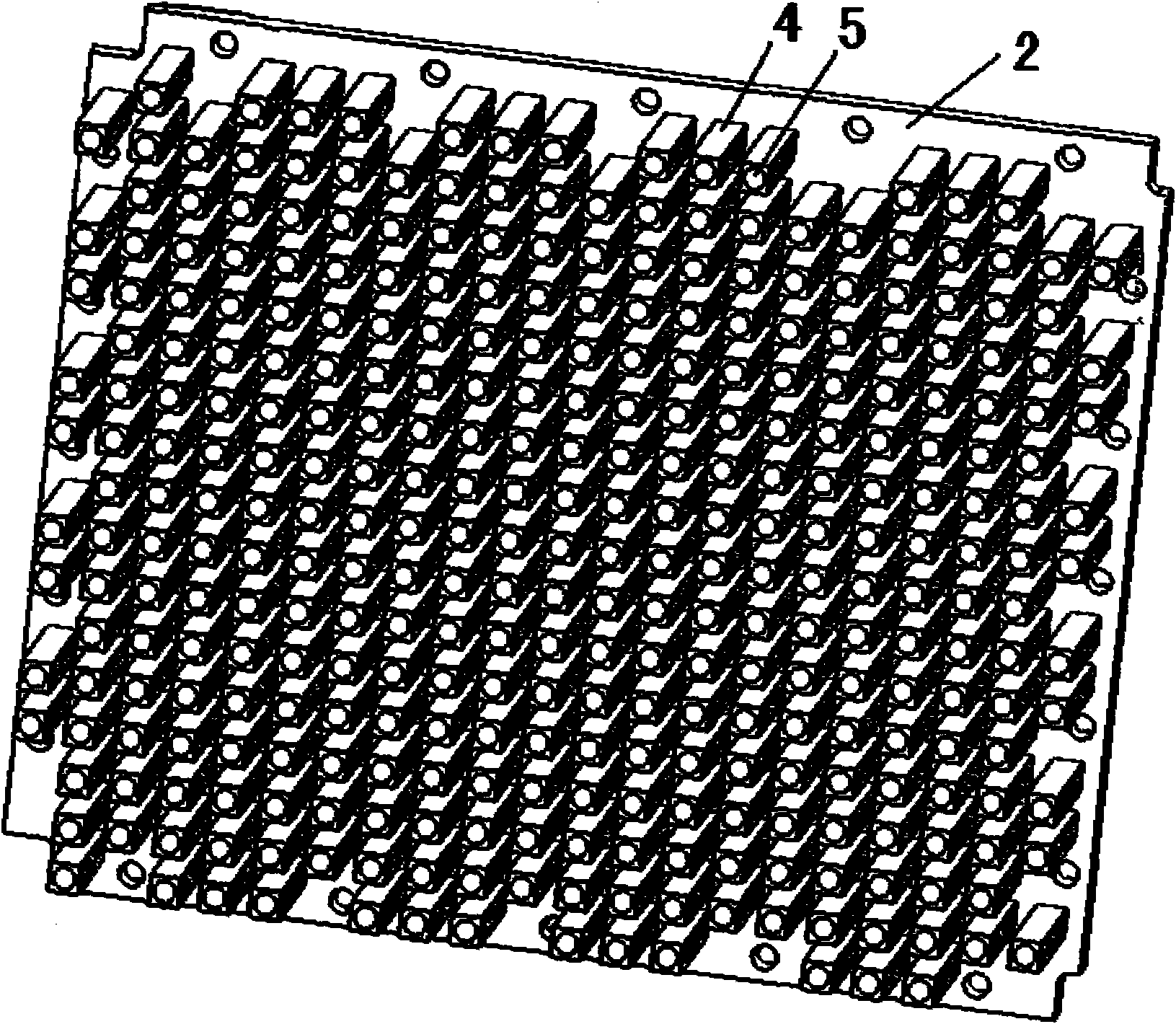

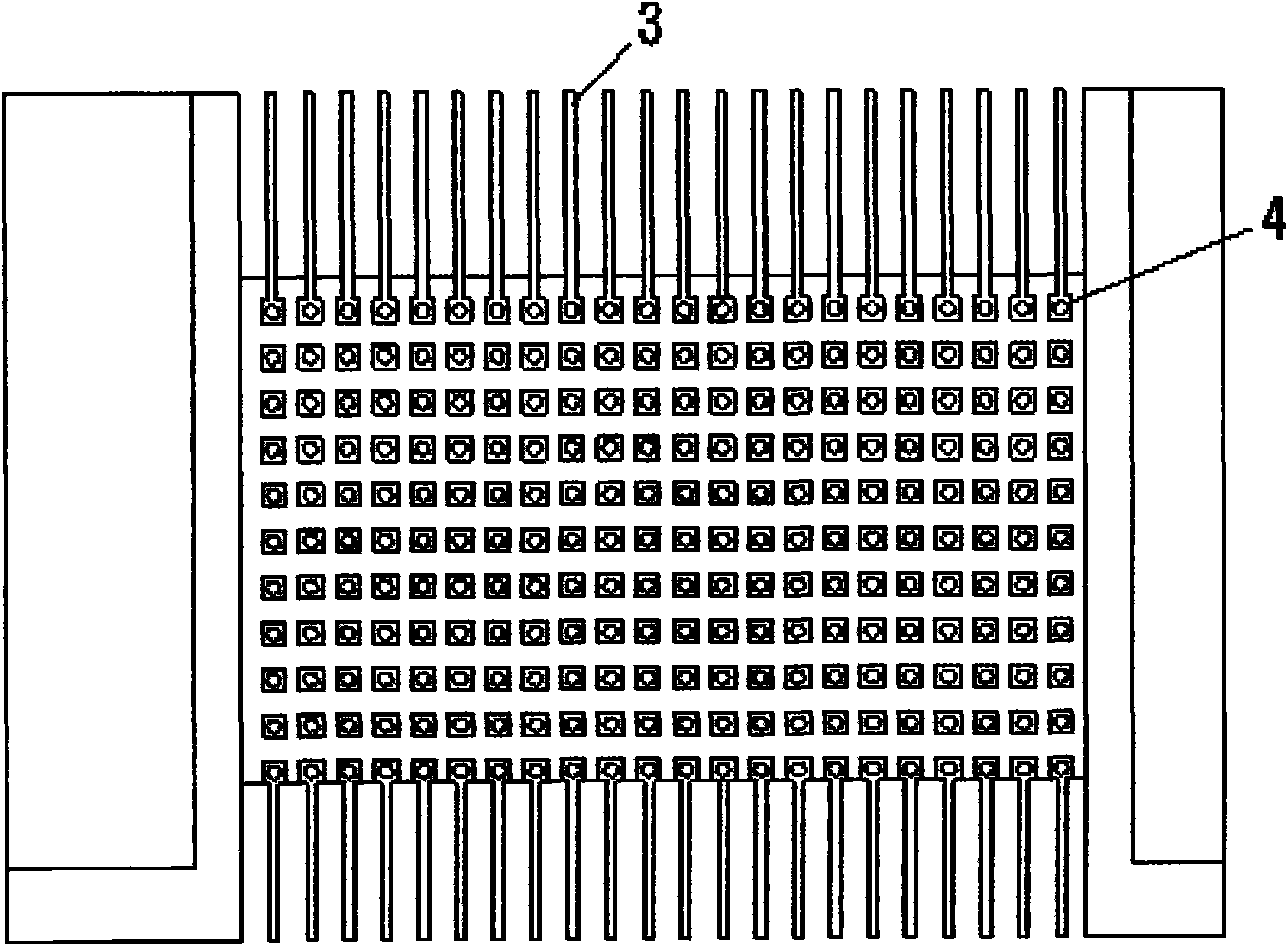

[0016] Example 1. like figure 1 , 2 As shown, the composition includes a shell 1 and a cover plate 2, heat dissipation fins 3 are processed on the edge of the shell 1, polygonal or circular shapes are processed on the surface of the shell 1 without the cover plate and the panel of the cover plate 2 The heat dissipation guide post 4 of the housing 1 edge is connected with the heat dissipation guide post 4 on the edge of the housing 1 (such as image 3 As shown), a deep hole 5 is drilled in the center of each heat dissipation guide post 4. Where the edge of the housing 1 is connected to the cover plate 2 , the heat dissipation guide post 4 is connected to the heat dissipation fin 3 of the same height, and the protruding height thereof is equivalent to the required height of the cover plate 2 .

[0017] During manufacture, a number of polygonal or circular heat dissipation guide pillars 4 are processed on the shell 1 of the radiator. The number of heat dissipation guide pillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com