A kind of carbon fiber composite material automobile exhaust pipe tailpipe and manufacturing method thereof

A composite material and manufacturing method technology, applied in the direction of exhaust devices, tubular objects, and other household appliances, can solve the problems affecting the normal operation of auto parts, difficult to install the car chassis, and large installation space, so as to improve the heat insulation effect , good heat insulation effect and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

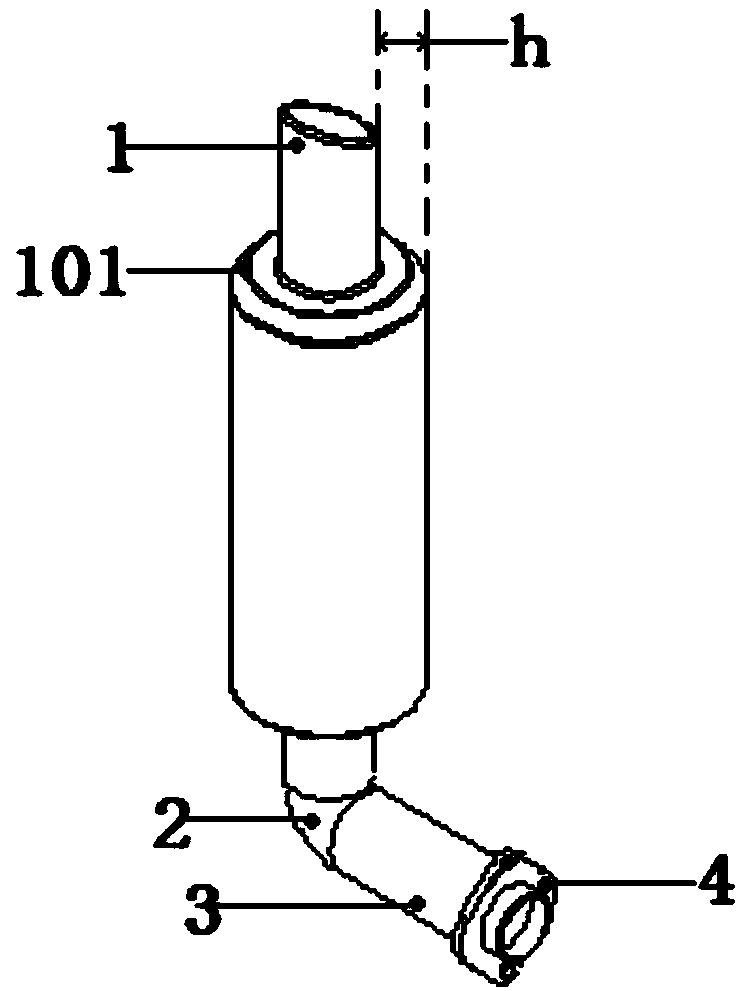

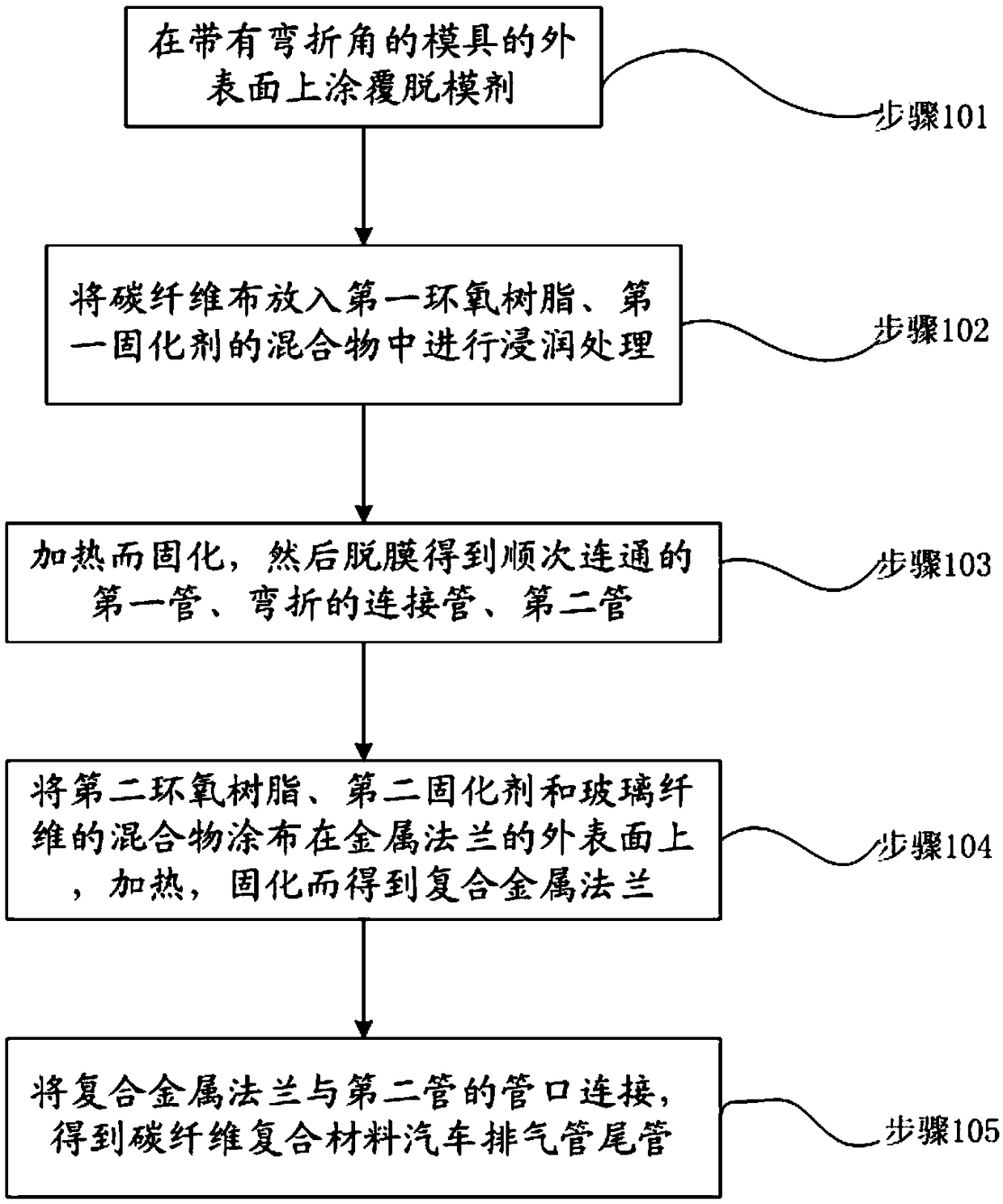

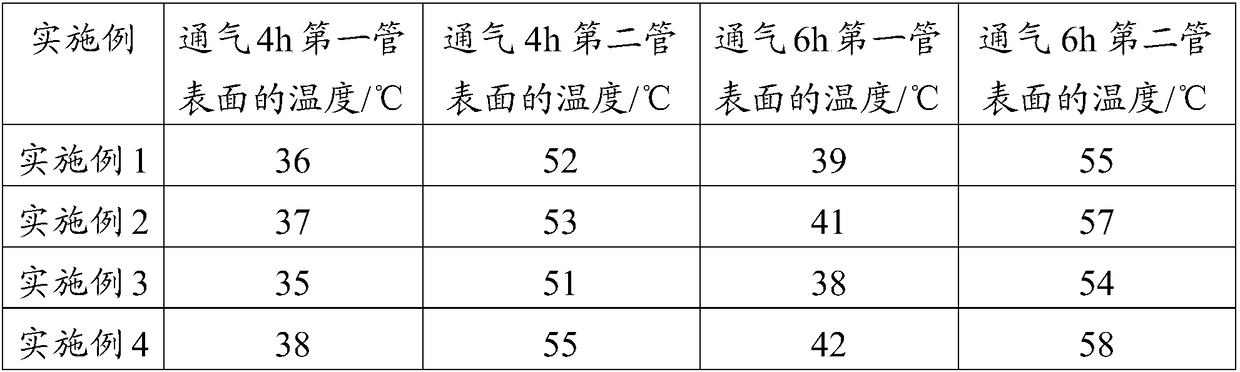

[0063] This embodiment provides a carbon fiber composite material automobile exhaust pipe tailpipe, which is manufactured by the following method: first prepare a sand mold bending mold made of sandy soil, and coat the aluminum skin on the surface of the sand mold bending mold Silicone oil, and then put the carbon fiber slanted cloth woven with 12K carbon fiber bundles into the mixture of E-44 type bisphenol A epoxy resin and polyamide with a mass ratio of 3:1 for infiltration treatment, and further follow the carbon fiber bundle The angles with the central axis of the sand mold bending mold are 0°, 45°, 90°, 0°, 90°, 45°, 0° and are wound on the sand mold bending mold, and the carbon fiber cloth is wound 14 layers, and the first The middle part of a pipe 1 is wound to form a boss 101 with a thickness of 28mm, and then the sand bending mold wrapped with carbon fiber cloth is put into a drying oven, heated at 125°C for 3 hours, then cooled to 50°C, kept for 20 minutes, and then ...

Embodiment 2

[0065] This embodiment provides a carbon fiber composite material automobile exhaust pipe tailpipe, which is manufactured by the following method: first prepare a sand mold bending mold made of sandy soil, and coat the aluminum skin on the surface of the sand mold bending mold Methyl silicone oil, then put the carbon fiber slanted cloth woven into E-56 type bisphenol A epoxy resin and polyamide with a mass ratio of 2:1 for infiltration treatment with 24K carbon fiber bundles, and further According to the angle between the carbon fiber bundle and the central axis of the sand mold bending mold is 0°, 45°, 90°, 0°, 90°, 45°, 0°, the carbon fiber bundle is wound on the sand mold bending mold, and the carbon fiber cloth is wound in 14 layers. And wind the middle part of the first pipe 1 to form a boss 101 with a thickness of 29mm, then put the sand bending mold wrapped with carbon fiber cloth into the drying oven, heat at 110°C for 2.5h, and then cool down to 56°C, Insulation for 3...

Embodiment 3

[0067]This embodiment provides a carbon fiber composite material automobile exhaust pipe tailpipe, which is manufactured by the following method: first prepare a sand mold bending mold made of sandy soil, and coat the aluminum skin on the surface of the sand mold bending mold Polyethylene wax, then the carbon fiber slant cloth woven into the carbon fiber bundle of 24K is put into the mixture of the mass ratio of E-44 type bisphenol A epoxy resin and aliphatic amine that is 3:1.5 to carry out infiltration treatment, further According to the angle between the carbon fiber bundle and the central axis of the sand mold bending mold is 0°, 45°, 90°, 0°, 90°, 45°, 0°, the carbon fiber bundle is wound on the sand mold bending mold, and the carbon fiber cloth is wound in 14 layers. And wind the middle part of the first pipe 1 to form a 26mm thick boss 101, then put the sand bending mold wrapped with carbon fiber cloth into the drying oven, heat it at 135°C for 3.5h, and then cool it dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com