Aerogel-based composite aluminum fiber acoustic panel absorber and preparation method thereof

An airgel-based, airgel-based technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of inorganic fiber sound-absorbing materials that are not easily decomposed, the sound absorption coefficient is reduced, and the use temperature is reduced. , to achieve the effect of convenient appearance design, good tensile strength and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

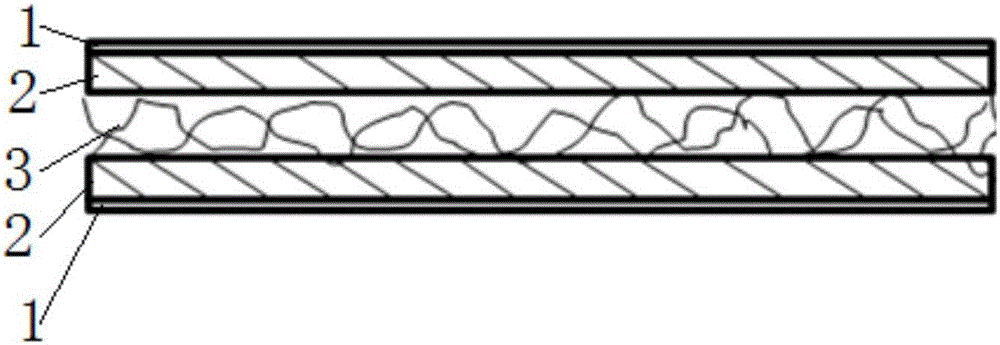

[0025] An airgel-based composite aluminum fiber sound-absorbing panel, such as figure 1 As shown, it includes aluminum stencil 1, airgel-based fiber felt 2 and aluminum fiber felt 3, the two sides of aluminum fiber felt 3 are bonded with airgel-based fiber felt 2, and the outside of airgel-based fiber felt 2 is bonded An aluminum stencil 1 is attached, an aluminum fiber mat 3 is made of aluminum fiber filaments with a thickness between 0.5 and 2 mm, and an airgel-based fiber mat 2 is a silicon oxide or iron oxide inorganic airgel fiber mat.

Embodiment 2

[0027] The density is 840g / m 2 Manufacturing of aluminum sound-absorbing panels

[0028] The aluminum fiber felt with a thickness of 0.5mm is sandwiched between two aluminum mesh panels glued with silica-based inorganic airgel fiber felt. The sandwich structure is rolled by a rolling machine and cured at room temperature to make a density of 840g / m 2 Aluminum sound-absorbing panels. The transverse tensile strength of aluminum fiberboard is about 70kg / cm 2 , the elongation rate is about 18%, and the longitudinal tensile strength is about 400kg / cm 2 , The elongation is about 12%.

Embodiment 3

[0030] The density is 1250g / m 2 Manufacturing of aluminum sound-absorbing panels

[0031] The aluminum fiber felt with a thickness of 2mm is sandwiched between two aluminum mesh panels glued with iron oxide-based inorganic airgel fiber felt. The sandwich structure is rolled by a rolling machine and cured at high temperature to make a density of 1250g / m 2 Aluminum sound-absorbing panels. The transverse tensile strength of aluminum fiberboard is about 80kg / cm 2 , The elongation is about 20%, the longitudinal tensile strength is about 500kg / cm2, and the elongation is about 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com