Sandwich water boiler

A hot water boiler and interlayer technology, applied in the field of boilers for heating water, can solve the problems of environmental pollution, increased energy consumption of circulating hot water, and insufficient hot water temperature, and achieve good mechanical strength and thermal stability, and thermal energy conversion. Fast speed, good heating and heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

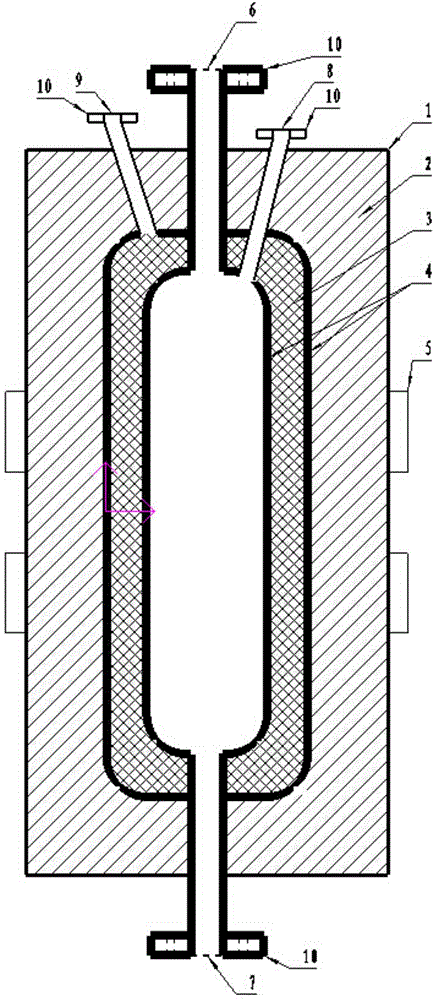

[0019] Such as figure 1 As shown, the present invention is a sandwich type hot water boiler. The boiler is composed of a carbon steel shell 1, a carbon fiber heat insulation layer 2, a quartz glass outer tank 4, and graphite injected by a feed pipe 9: silicon carbide from the outside to the inside of the boiler. = 1:1 powdery mixed filling induction heating layer 3, quartz glass liner, the top of the boiler is provided with carbon steel plate shell 1, carbon fiber heat insulation layer 2, quartz glass outer liner 4, The induction heating layer 3, the quartz glass liner and the water inlet pipe 6 and the exhaust pipe 8 opening in the quartz glass liner cavity, the bottom of the boiler are provided with the carbon steel shell 1, the carbon fiber heat insulation Layer 2, quartz glass outer tank 4, ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com