Mechanical reversing speed reducer and vertical type pumping unit

A technology of mechanical reversing and reducer, which is applied in the direction of mechanical equipment, mining fluid, gear transmission, etc. It can solve the problems of difficulty in maintenance and replacement of reversing mechanism, difficulty in heat dissipation, and shortened service life, so as to achieve the effect of lowering temperature and lubricating Guaranteed to achieve the effect of power output direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

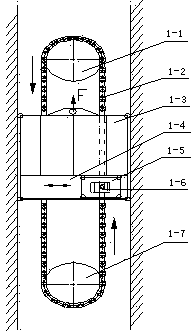

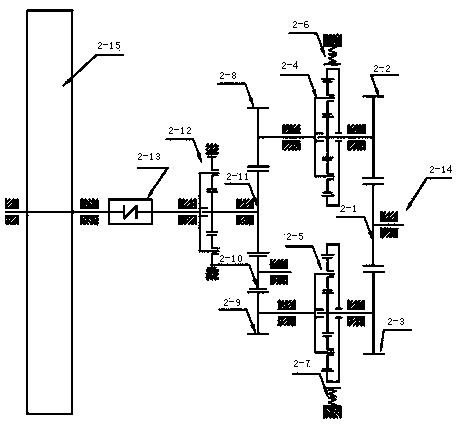

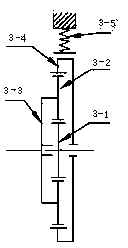

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] It should be understood that the accompanying drawings only depict a preferred embodiment of the present invention, and thus the accompanying drawings should not be construed as limiting the scope of the present invention, which is only limited according to the claims.

[0036] see figure 2 , is a schematic diagram of an embodiment of the mechanical reversing reducer of the present invention. The input end 2-14 is connected to the driving gear 2-1 of the power distribution gear set, the driven gear 1 2-2 and the driven gear 2 2-3 mesh with the driving gear 2-1 on both sides, and the power passes through the driven gear respectively. Gear one 2-2 and driven gear two 2-3 transmit to planetary gear train one 2-4 and planetary gear train two 2-5. The ring gears of planetary gear system 1 2-4 and planetary gear system 2 2-5 are respectively equipped with brake 1 2-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com