Method for producing liquid methyl tetrahydrophthalic anhydride

A technology of methyltetrahydrophthalic anhydride and its production method, which is applied in the direction of organic chemistry, can solve problems such as deep color depth, high viscosity, and poor stability, and achieve the effects of low freezing point, low toxicity, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

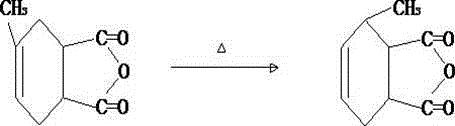

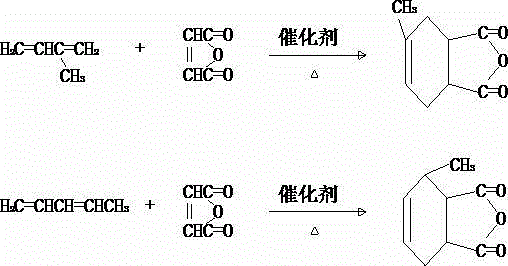

Image

Examples

Embodiment 1

[0020] A kind of production method of liquid methyltetrahydrophthalic anhydride, take piperylene, isoprene, maleic anhydride as main raw material, the production method of described liquid methyltetrahydrophthalic anhydride comprises the following steps:

[0021] (1) Use the carbon five pump to transport the quantitative piperylene and isoprene to the carbon high-level metering tank, and move it into the diene reaction kettle;

[0022] (2) Add a certain amount of maleic anhydride to the molten anhydride, heat it to melt it all, the temperature is 120°C, the pressure is 2kg / cm 2 ;

[0023] (3) Turn on the jacket of the diene reactor and heat until C5 reflux occurs, stop heating, slowly drop the melted maleic anhydride into the diene reactor, and pay attention to the changes in temperature and pressure;

[0024] (4) After the dropwise addition, keep warm for 2 hours. After the sampling is qualified, close the reflux valve, open the carbon five recovery valve, and slowly raise t...

Embodiment 2

[0029] A kind of production method of liquid methyltetrahydrophthalic anhydride, take piperylene, isoprene, maleic anhydride as main raw material, the production method of described liquid methyltetrahydrophthalic anhydride comprises the following steps:

[0030] (1) Use the carbon five pump to transport the quantitative piperylene and isoprene to the carbon high-level metering tank, and move it into the diene reaction kettle;

[0031] (2) Add a certain amount of maleic anhydride into the molten anhydride, heat it to melt it all, the temperature is 135°C, and the pressure is 2kg / cm 2 ;

[0032] (3) Turn on the jacket of the diene reactor and heat until C5 reflux occurs, stop heating, slowly drop the melted maleic anhydride into the diene reactor, and pay attention to the changes in temperature and pressure;

[0033] (4) After the dropwise addition, keep warm for 4 hours. After the sampling is qualified, close the reflux valve, open the carbon five recovery valve, and slowly r...

Embodiment 3

[0038] A kind of production method of liquid methyltetrahydrophthalic anhydride, take piperylene, isoprene, maleic anhydride as main raw material, the production method of described liquid methyltetrahydrophthalic anhydride comprises the following steps:

[0039] (1) Use the carbon five pump to transport the quantitative piperylene and isoprene to the carbon high-level metering tank, and move it into the diene reaction kettle;

[0040] (2) Add a certain amount of maleic anhydride to the molten anhydride, heat it to melt it all, the temperature is 150°C, and the pressure is 2kg / cm 2 ;

[0041] (3) Turn on the jacket of the diene reactor and heat until C5 reflux occurs, stop heating, slowly drop the melted maleic anhydride into the diene reactor, and pay attention to the changes in temperature and pressure;

[0042] (4) After the dropwise addition, keep warm for 6 hours. After the sampling is qualified, close the reflux valve, open the carbon five recovery valve, and slowly rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com