Mounting structure of muffler outer hood of snow remover

A technology for installing structure and muffler, which is used in intake muffler, snow surface cleaning, construction, etc., can solve the problems of high temperature of muffler cover, small welding force area, easy rupture of muffler, etc. The effect of factors that have little effect on welding and increase the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

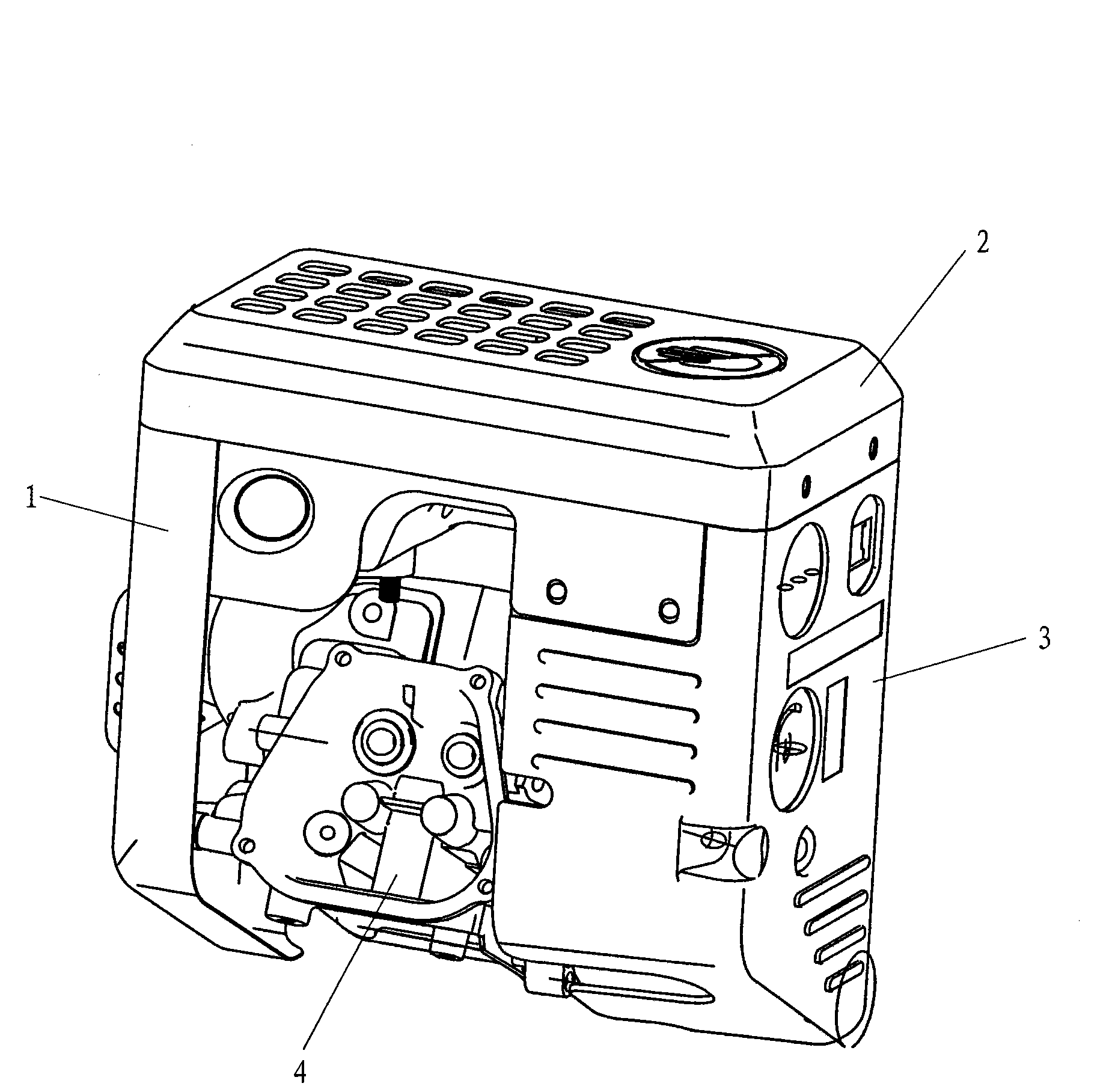

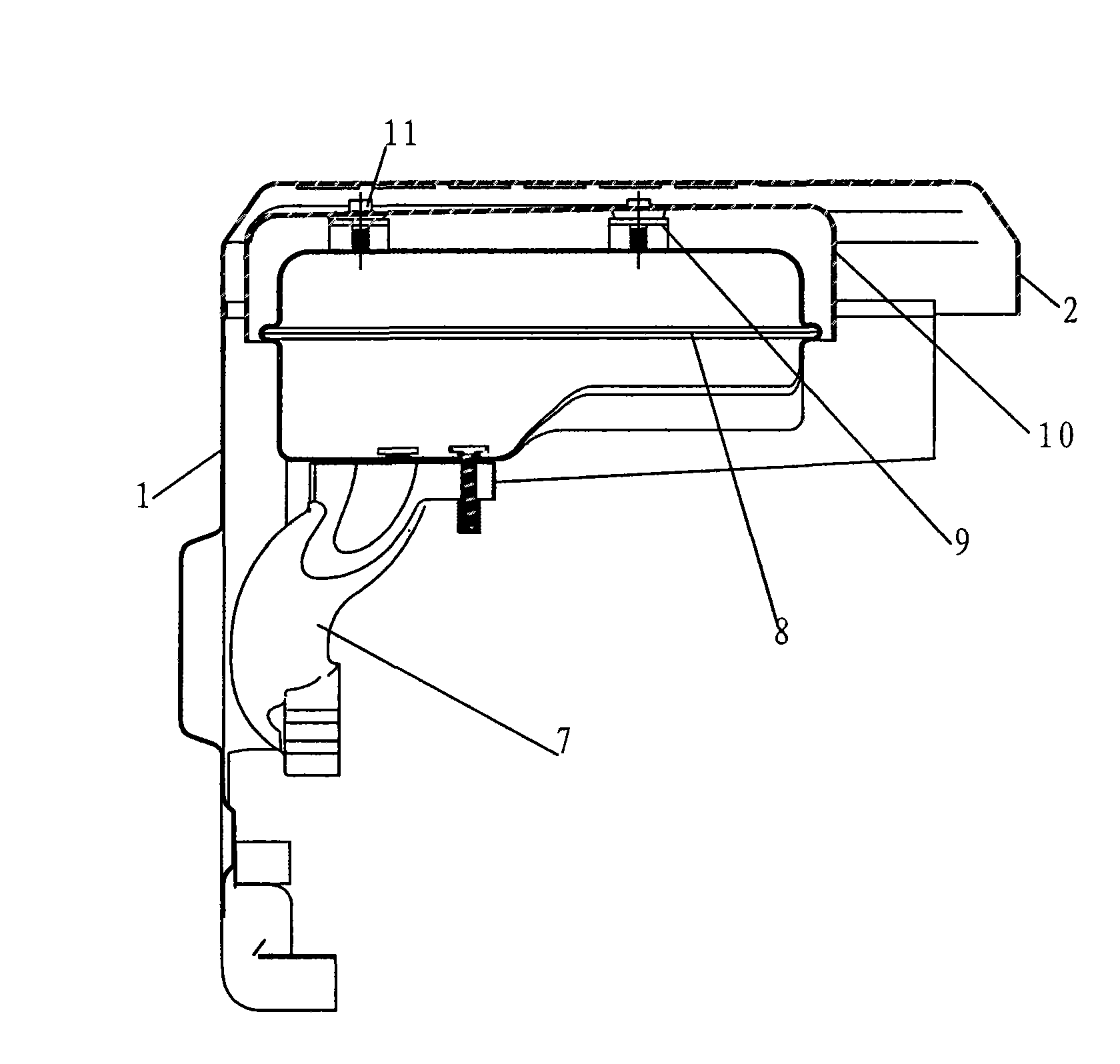

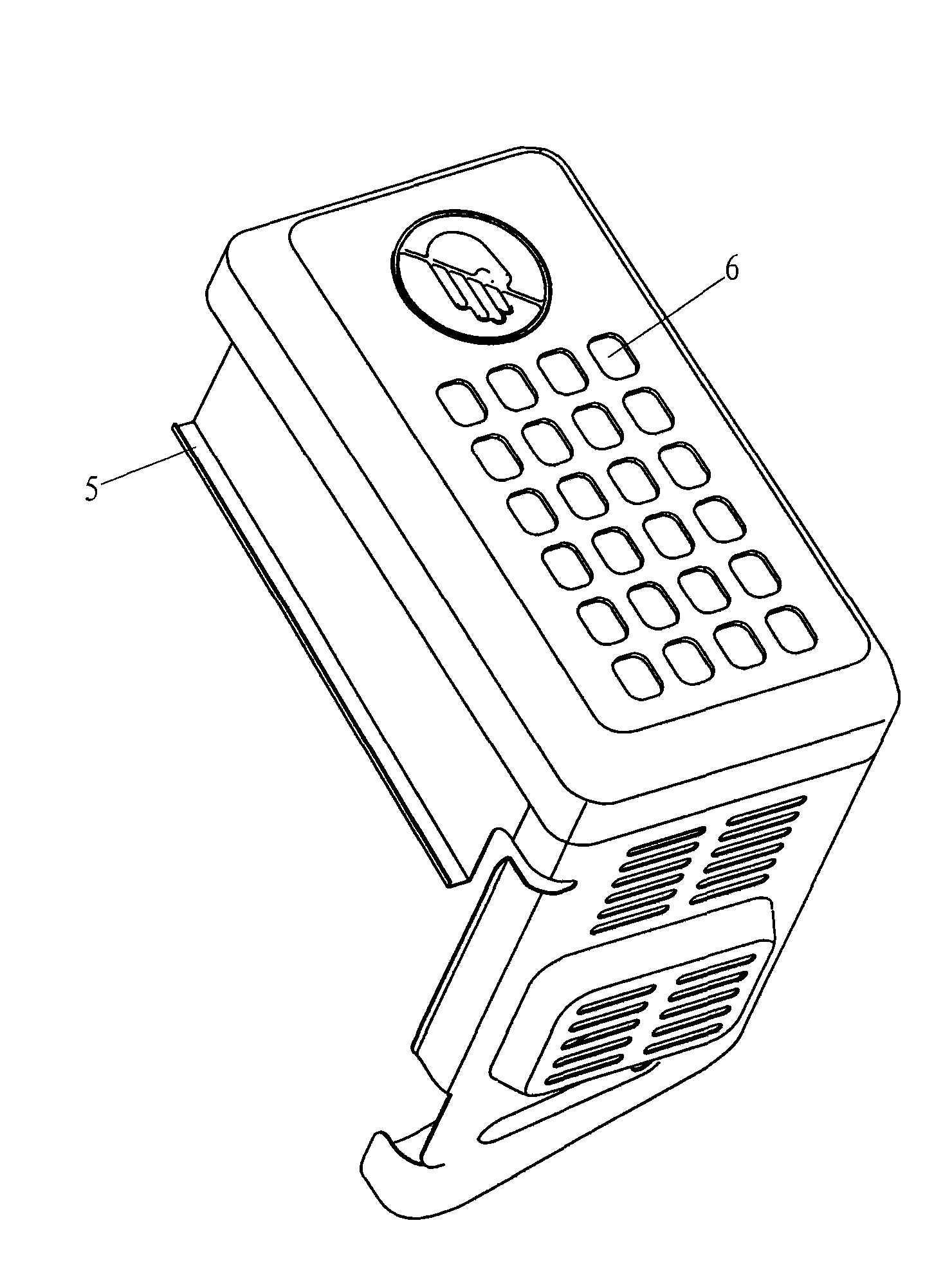

[0016] see Figure 1-Figure 3 Two brackets 9 are arranged on the top of the muffler 8, the brackets run through the top of the muffler, and the two ends of the brackets are welded on both sides of the muffler to connect the inner cover 10 with the bracket at the top of the muffler by bolts 11. Outer cover 2 is positioned at the outside of inner cover, and the two sides of described outer cover are provided with drainage groove 5, make the heat that snowplow machine produces when working, the water that will adhere to the snowplow machine and melt ice and snow that produces flows out along the drainage groove. snow machine. The top of the outer cover is provided with radiating holes 6 to dissipate the heat generated when the snowplow works in time. One end of the outer cover is welded to one end of the muffler cover 1, the other end of the outer cover is bolted to the air filter housing 3, the cylinder head 5 is fixed in the air filter housing, the shield and the outer cover b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com