Weatherstrip with ventilation openings

A technology of sealing strips and air holes, which is applied in the direction of engine sealing, sealing devices, engine components, etc., can solve the problems of shortening the life of components and easy penetration of dust, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

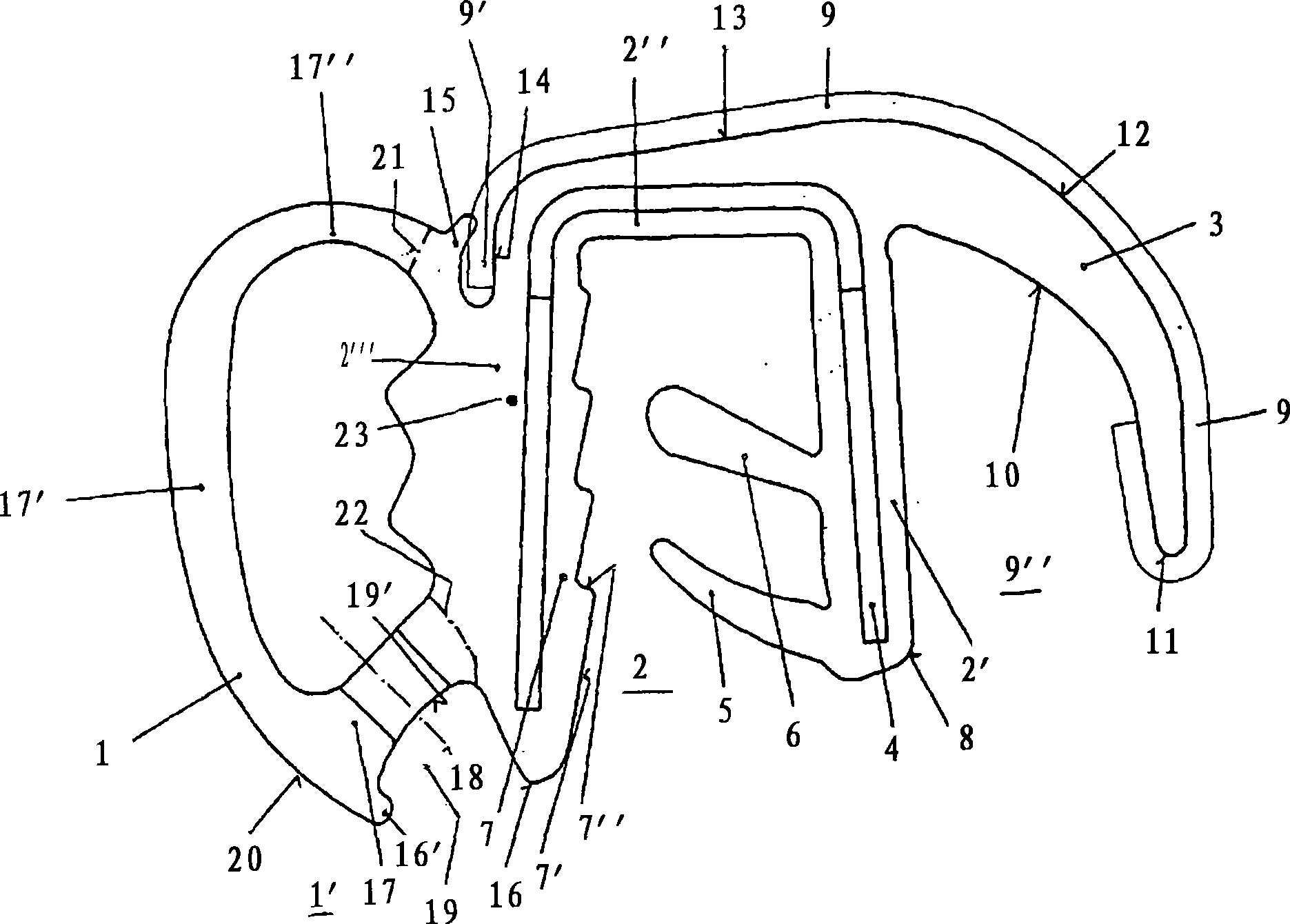

[0018] The profile is a side-by-side structure, which is arranged side by side by a hollow profile-shaped sealing part 1, a U-shaped fastening part 2, and a strip 3 formed on the side of the fastening part 2, wherein the strip 3 mainly constitutes the covering plate.

[0019] A similar U-shaped metal reinforcement 4 is provided on the fastening part 2 and is to be positioned on a flange (not shown in the figure) which is attached to the edge of the opening in the vehicle. In order to stabilize the fitting of the fastening part 2 on this flange, flexible tongues 5, 6 are provided on the inner surface of the fastening part, which generally extend from the right branch 2' in a mutual direction. Parallel spacings extend out and, relative to the U-shaped profile of the fastening part 2 , inwards in the direction towards the profile base 2 ″. In addition, on the inside of the fastening part 2 opposite the flexible tongues 5 , 6 Above, a saw-tooth-shaped structure 7 is provided, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com