C-axis sapphire polishing solution and preparation method thereof

A polishing liquid, sapphire technology, applied in the field of sapphire polishing, to achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

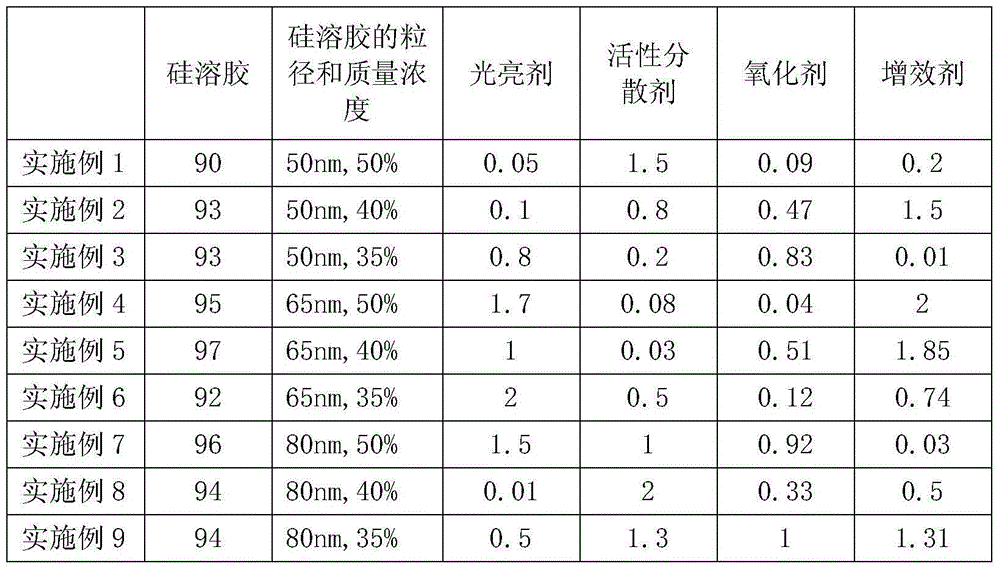

Examples

preparation example Construction

[0026] The preparation method steps of above-mentioned C to sapphire polishing liquid are as follows:

[0027] (1) Use a 500-mesh screen filter system to remove impurity particles in the silica sol raw material;

[0028] (2) Control the rotational speed between 60-120rpm, add the brightener and active dispersant while stirring the silica sol with the above-mentioned filtered concentration of 35%-50% at a flow rate of 0.5-2.0L / min, the flow rate is too fast It will lead to too high local reagent concentration of silica sol, which will lead to increased viscosity or even crystallization, which will affect the use effect;

[0029] (3) Continue to add oxidant and synergist to the closed reaction tank at a flow rate of 0.5-2.0 L / min in sequence, and adjust the pH value to 10-11 with the synergist to prepare a sapphire polishing solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com