Cutting method for plane body cover during emergency decompression in passenger plane test flight

A technology of fuselage skin and cutting method, which is applied in the direction of weapon accessories, blasting barrels, offensive equipment, etc., to achieve the effect of reducing the amount of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

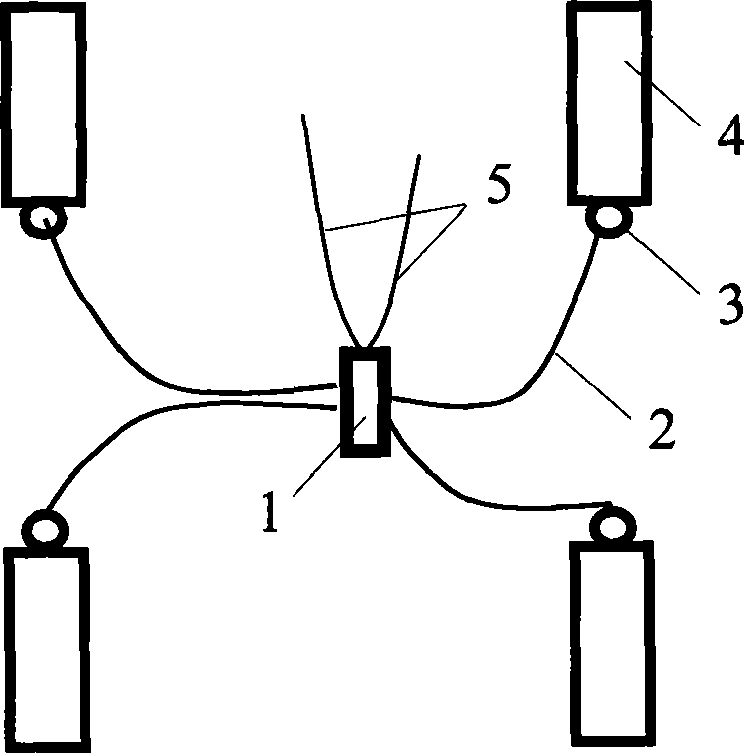

[0030] like Figure 4 As shown, the explosion cutting position is the skin frame between SD866 and SD878.926 in the rear section of the ARJ21-700 passenger cabin, on the skin between the left and right 8th and 9th stringers and the 10th and 11th stringers. Out of four openings A, the total area is not less than 0.055m 2 , not more than 0.06m 2 , the edge of the opening is smooth, and the distance between each side of the stringer and the frame is not less than 30mm. The thickness of the skin here is 1.6mm.

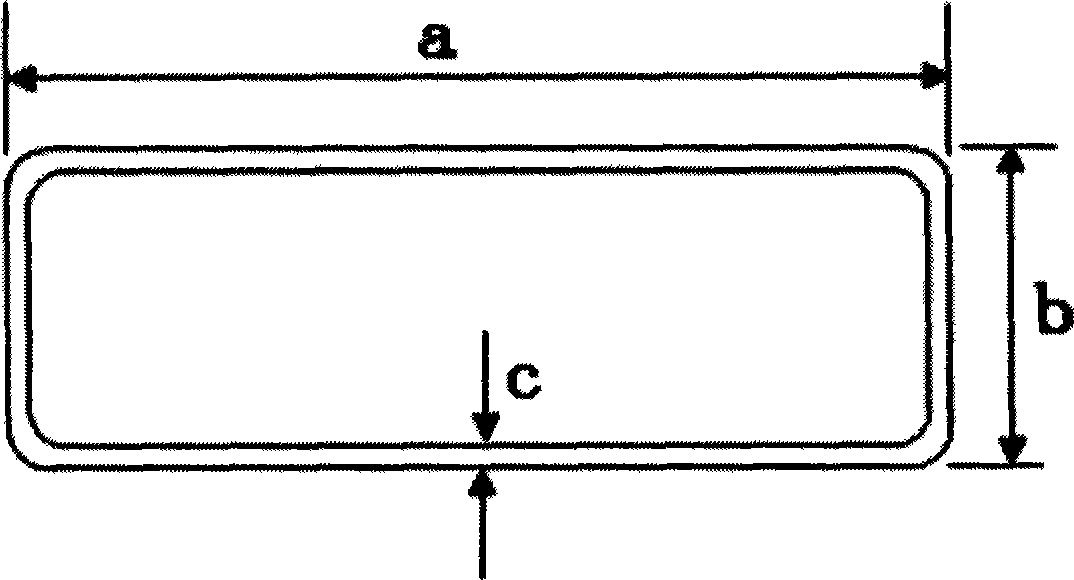

[0031] like figure 1 As shown, the shape of the incision is a closed rectangle, and the specific parameters are set as length a=140mm and width b=120mm.

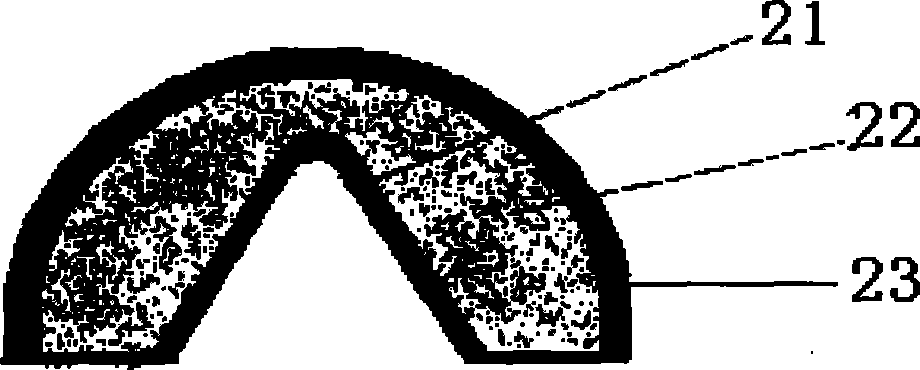

[0032] like figure 2 As shown, the cutter adopts a flexible energy-concentrating cutter with lead-antimony alloy as the drug-type cover and shell material. The charge is A5 explosive, and the charge is 1.8g / m, which can reliably cut the skin material with a thickness of 2.1mm. . in. 21 is a drug type cover, 22 i...

Embodiment 2

[0036] The shape of otch is set to circle, and the shape of cutter is also set to circle, and other conditions are all carried out by embodiment 1,

[0037] The method was successfully used in the acceptance test of the emergency opening system of the service cabin door during the flight test stage of the passenger aircraft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com