Water plugging method suitable for shallow earth surface large-open-degree fractured rock mass roadway

A technology with large openings on the surface and cracked rock mass, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as unsatisfactory engineering requirements, fractured rock mass instability, equipment submersion, etc., to reduce flood disasters, The effect of ensuring mine safety and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A water plugging method suitable for rock mass tunnels with large openings on the shallow surface, characterized by comprising the following steps:

[0049] 1) Selection of dry soybean particle size: After grinding the dry soybean into particles, the particle size of the dry soybean is selected according to the bonding degree of the fissure rock mass fissure. After investigation, the rock mass in the roadway is a rock mass with an average bonding degree. According to The combined degree of the cracks in the fractured rock mass is selected as the particle size of dry soybean particles is 14 mesh, accounting for 20%, 18 mesh accounting for 30%, and 20 mesh accounting for 50%.

[0050] 2) Grouting material and ratio: The grouting material is cement-water glass, and water and quick-setting agent are added, and the ratio of water, cement and water glass is 0.8:1:0.75. The quick-setting agent accounts for water, cement and water 2% of the total glass.

[0051] 3) Determinati...

Embodiment 2

[0069] A water plugging method suitable for rock mass tunnels with large openings on the shallow surface, characterized by comprising the following steps:

[0070] 1) Selection of dry soybean particle size: According to the survey results, the fracture bonding degree of the rock mass in this area is poor, so the particle size of dry soybean particles is selected as 12 mesh, 10%, 14 mesh, 22%, 18 mesh, 30%, 20 mesh accounts for 38%;

[0071] 2) Grouting material and ratio: The grouting material is cement-water glass, and water and quick-setting agent are added, and the ratio of water, cement and water glass is 0.8:1:0.75, and the quick-setting agent accounts for water, cement and 3.5% of the total amount of water glass.

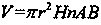

[0072] 3) Determination of grouting parameters: grouting parameters include grouting pressure, diffusion radius and theoretical injection volume;

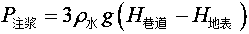

[0073] The grouting pressure value is determined according to the following formula:

[0074]

[0075] In ...

Embodiment 3

[0090] A water plugging method suitable for rock mass tunnels with large openings on the shallow surface, characterized by comprising the following steps:

[0091] 1) Selection of dry soybean particle size: According to the survey results, the fracture bonding degree of the rock mass in this area is very poor, so the particle size of dry soybean is selected as 12 mesh, 8%, 14 mesh, 18%, 18 mesh, 32%, and 20 mesh. accounted for 42%;

[0092] 2) Grouting material and ratio: The grouting material is cement-water glass, and water and quick-setting agent are added, and the ratio of water, cement and water glass is 0.8:1:0.75. The quick-setting agent accounts for water, cement and water 6% of the total glass.

[0093] 3) Determination of grouting parameters: grouting parameters include grouting pressure, diffusion radius and injection volume;

[0094] The grouting pressure value is determined according to the following formula:

[0095]

[0096] In this example, the surface el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com