Reinforcement sleeve grouting material compactness detection system and detection method

A technology of compactness detection and steel sleeve, which is applied in the direction of measuring device, specific gravity measurement, analysis of materials, etc., can solve the problems of narrow sleeve space, affecting the construction industrialization, and the detection and acceptance method cannot be tested, etc., and achieves simple and fast operation. , the effect of short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

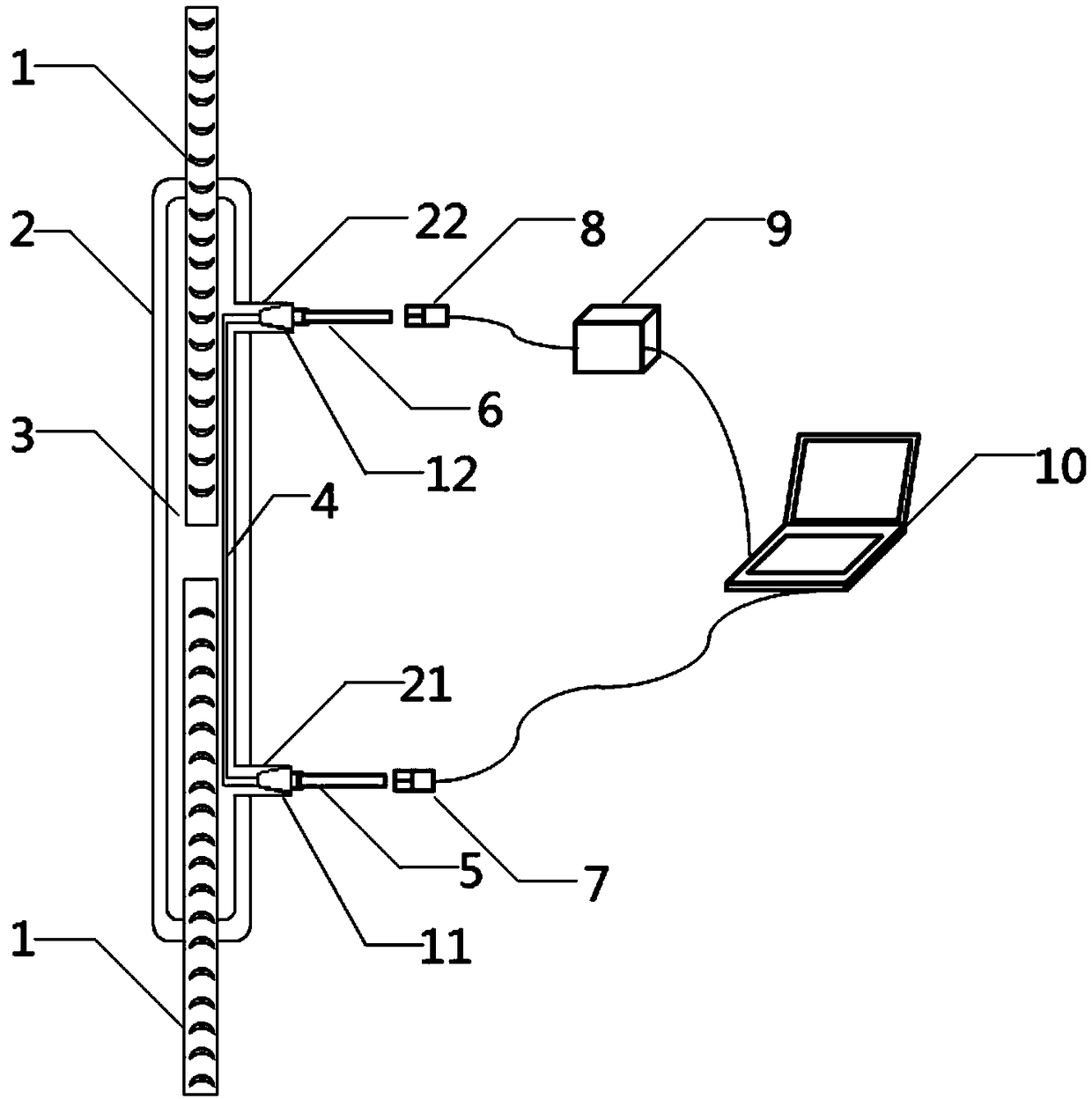

[0040] This embodiment discloses a system for detecting the density of grouting materials in steel bar sleeves, such as figure 1 As shown, it includes a sleeve 2 for connecting the steel bar 1, and the inside of the sleeve 2 is provided with a grouting material 3 through the grout inlet 21 and the grout outlet 22 provided on the sleeve 2, and is characterized in that:

[0041] A signal conduction rod 4 is also arranged inside the sleeve 2, and a data acquisition device is arranged outside the sleeve 2;

[0042] The data acquisition device comprises a signal transmitter 7, a signal receiver 8 and a data processor 10 for statistical analysis of signals, and the signal transmitter 7 and the signal receiver 8 are all electrically connected to the data processor 10;

[0043] One end of the signal conducting rod 4 is connected to the signal transmitter 7 through the pulp inlet 21, and the other end of the signal conducting rod 4 is connected to the signal receiver 8 through the pulp...

Embodiment 2

[0065] This embodiment discloses a system for detecting the density of grouting materials in steel bar sleeves. The structural difference between it and Embodiment 1 lies in:

[0066] In this embodiment, the signal transmitter 7 is an oscillator for transmitting vibration waves.

[0067] The detection method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0069] This embodiment discloses a detection method of a detection system for the density of grouting materials in steel bar sleeves, and its difference from Embodiment 1 in steps lies in:

[0070] S3. When the grouting material 3 in the sleeve 2 reaches half, set the seals on both ends of the signal transmission rod 4 and seal the grout inlet 21 and the grout outlet 22 to form a sleeve connector;

[0071] All the other steps are the same as in Example 1.

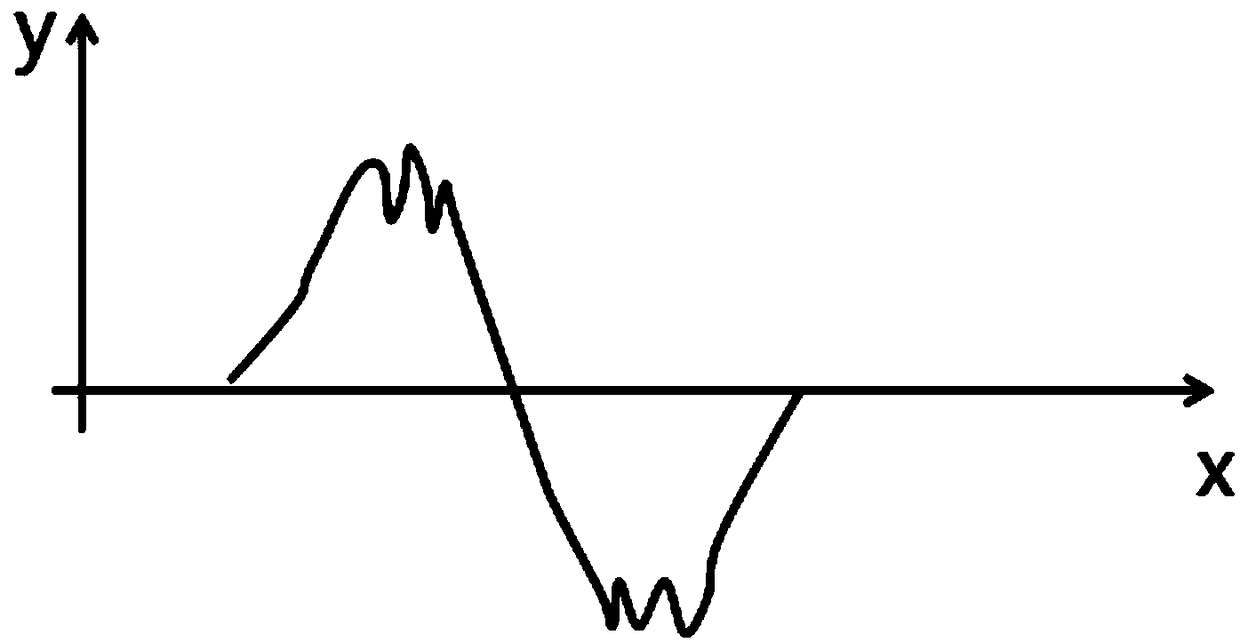

[0072] The detection result of this embodiment is as follows Figure 5 As shown, in the figure, the abscissa x is the receiving time, and the ordinate y is the amplitude of the sound wave; compare the reference example of the present embodiment Image 6 As shown, it can be seen that the filling of the grouting material 3 in the sleeve 2 detected in this embodiment is not dense.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com