Construction method of composite column integrally formed by 3D printing and knitting and composite column

A 3D printing and construction method technology, applied in the field of composite columns, can solve the problems of non-integrated molding of 3D printing columns and FRP column outer cladding, achieve flexible compatibility and universality, improve tensile strength, reduce Effects of Building Construction Procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

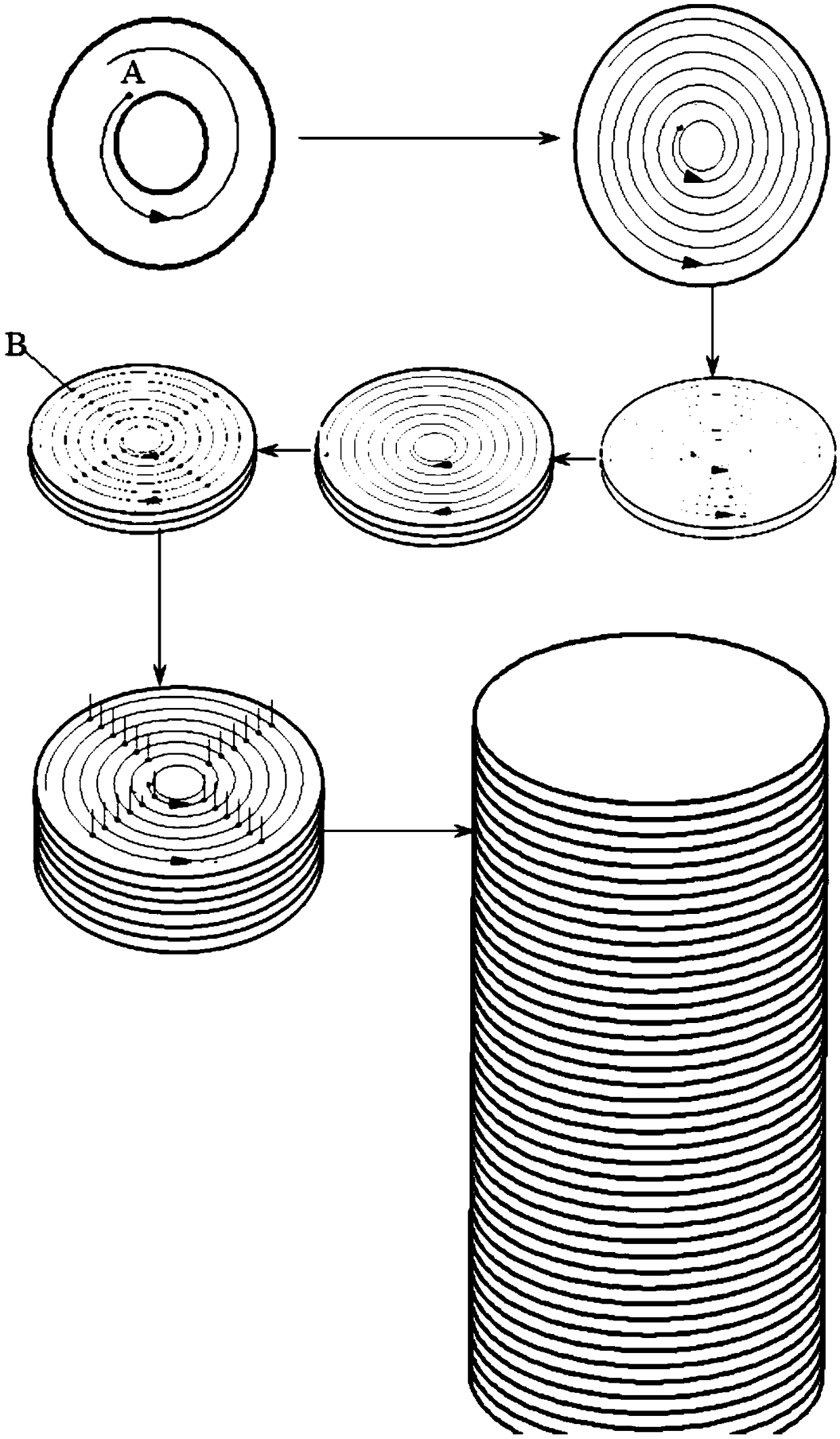

[0042] This embodiment takes the example of printing a woven anti-seismic structural column.

[0043] Step 1: After modeling the seismic structural column modeling space, optimize the space shape according to the functional requirements, and design the weaving density of the wires according to the bearing capacity requirements.

[0044] The second step: according to the determined space shape and weaving density, arrange the printing sequence of the substrate and the anchor points of the wires to obtain the integrated process of printing and weaving; and prepare 3D printing materials.

[0045] Step 3: Print the solid composite column layer by layer according to the integrated process of printing and weaving.

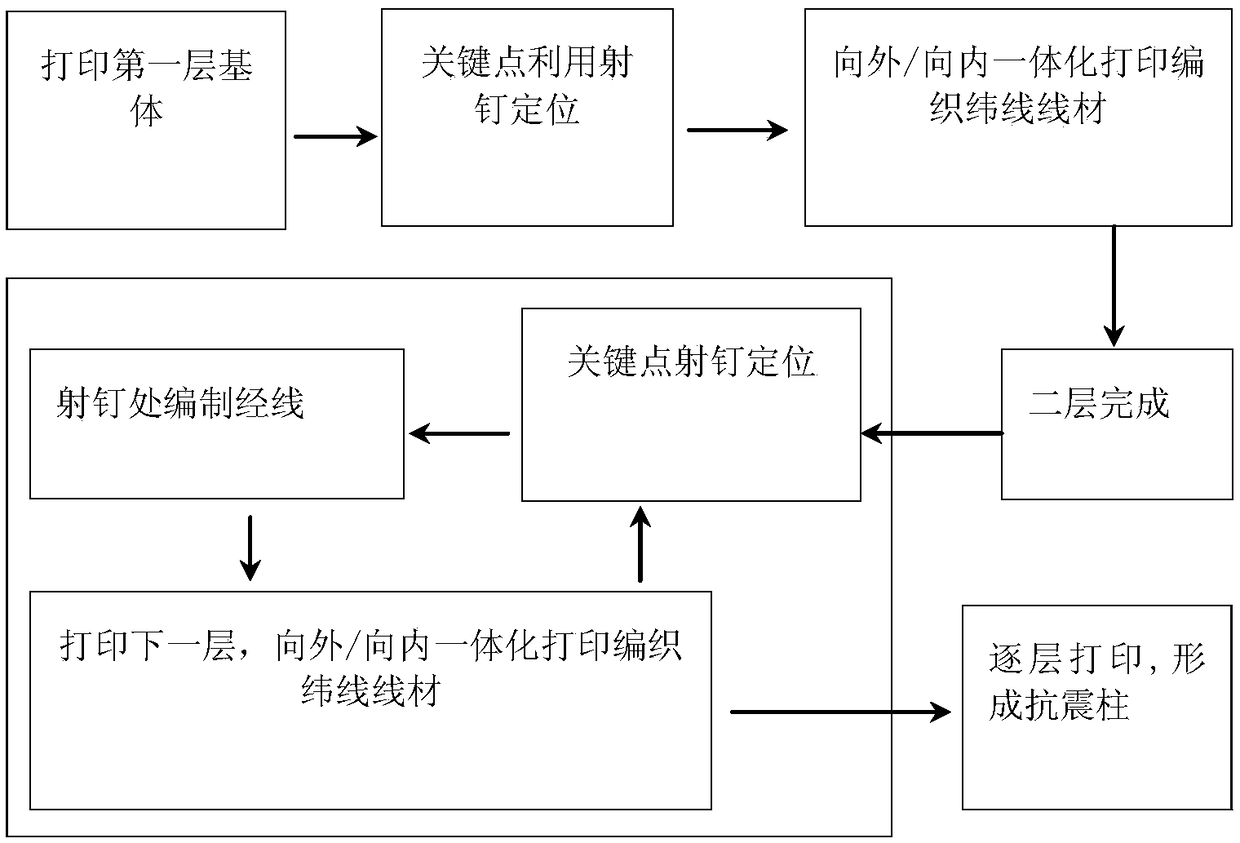

[0046] Specifically, as figure 1 The printing and weaving integration process shown is:

[0047] (2-1) Print the substrate outward / inward;

[0048] (2-2) Spray screw positioning at the anchor point;

[0049] (2-3) Inward / outward integrated printing of braided weft wi...

Embodiment 2

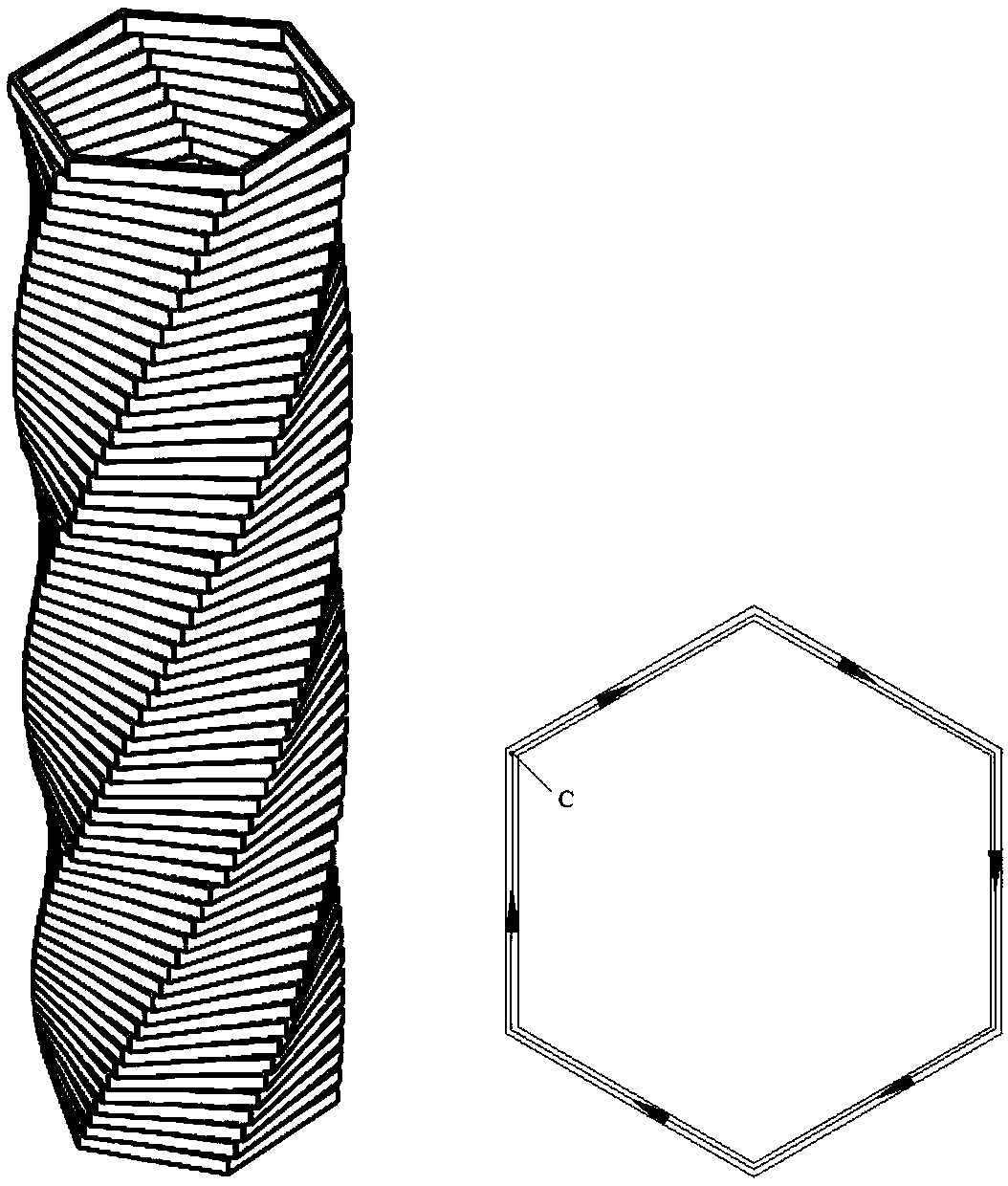

[0055]In this embodiment, the shell 1 of the woven space composite column is 3D printed and combined with the existing reinforced concrete structural column.

[0056] Step 1: Design of the overall structure of special-shaped columns: Firstly, design the special-shaped columns and their shells according to the requirements of architectural modeling, such as image 3 As shown; according to the structure, interlayer shear resistance and stiffness requirements during the construction period, the thickness of the special-shaped column shell and the size and density of the ribs are determined, and the weaving density is designed according to the requirements of crack resistance, deformation and bearing capacity.

[0057] Step 2: According to the determined space shape and weaving density, arrange the printing sequence of the substrate and the anchoring points of the wires to obtain the integrated process of printing and weaving.

[0058] The integrated process of printing and weavin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com