3D weaving and printing integrated structure construction equipment

A kind of equipment and 3D technology, applied in building construction, construction, manufacturing tools, etc., can solve the problems that the process cannot be applied to construction projects, the printing matrix enhancement efficiency is low, and the adaptation range is narrow, so as to improve the level of digital intelligence integration and reduce The effect of building structure production and construction on carbon emissions and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention are described below, and those skilled in the art will be able to implement them using related technologies in the field as described below, and can better understand the innovations and benefits of the present invention.

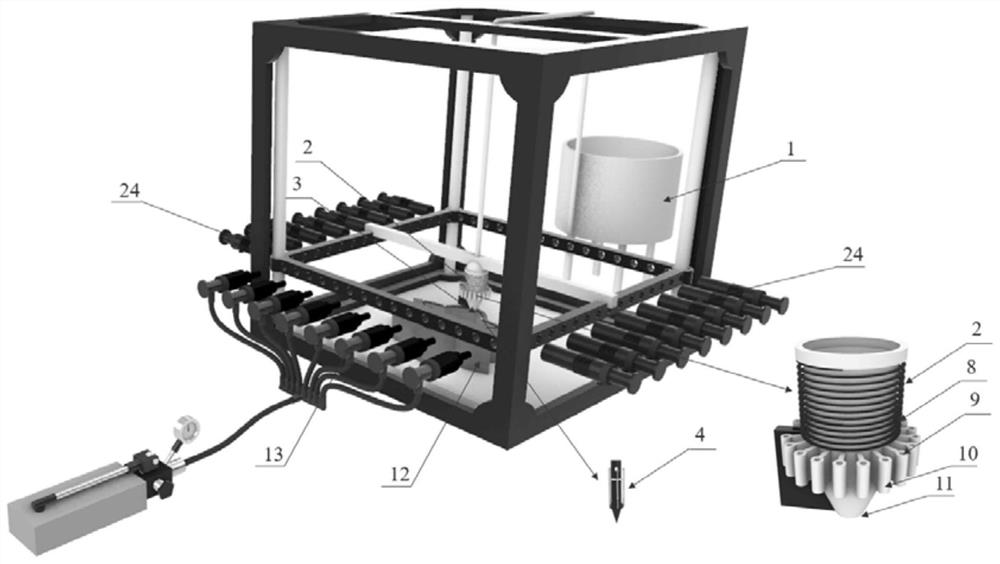

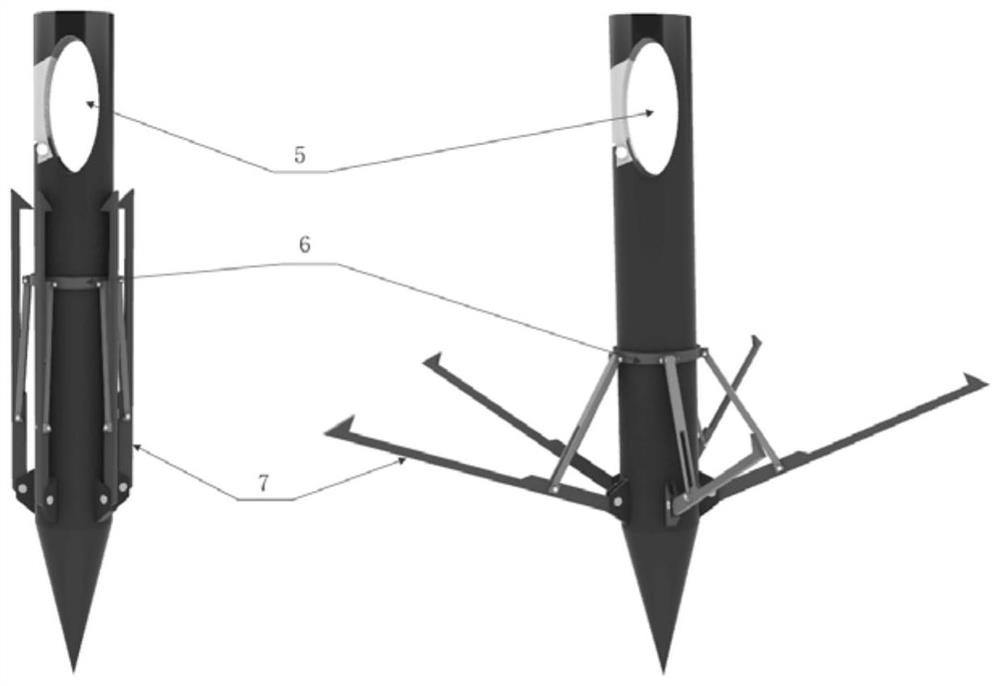

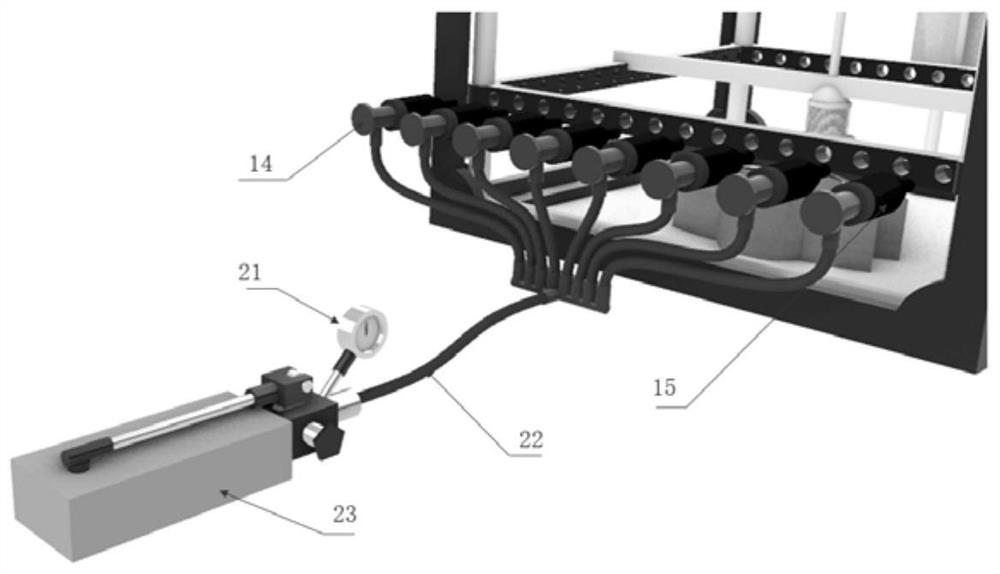

[0042] Such as Figure 1-5 As shown, the 3D printing and weaving integrated construction machine adopted in the present invention includes: a printing substrate preparation device 1, a printing substrate extruding device 3 and a wire pushing and space anchoring device 4 that are arranged on the equipment support and can be moved in space, fixed on the equipment support The tension traction device 14, the electromagnetic guidance picking device 24.

[0043] Its usage method is:

[0044] 1. Print the substrate and weave the rope / thread / cable material in the vertical direction

[0045] (1) Use the printing substrate preparation device 1 to prepare the printing substrate and transport it to the printing su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com