3D-printed negative pressure isolation ward establishing method based on topology optimization

A 3D printing and topology optimization technology, applied in hospitals, schools, prisons, etc., can solve the problems of air tightness and structural safety, stability, durability, poor thermal insulation and sound insulation performance, and air/water Poor sealing performance and other problems, to achieve the effect of ensuring airtightness and safety, easy cleaning and disinfection, and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The preferred embodiments of the present invention will be described with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

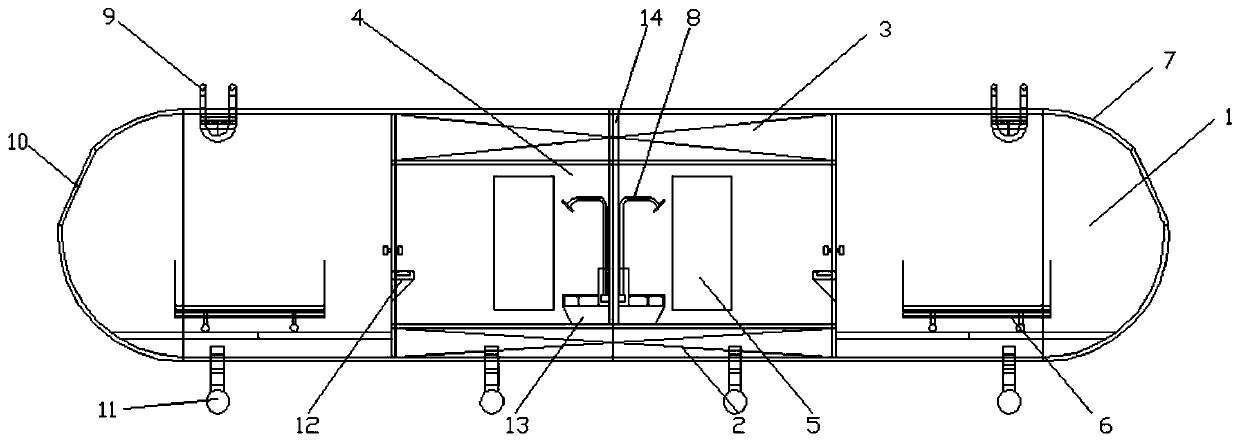

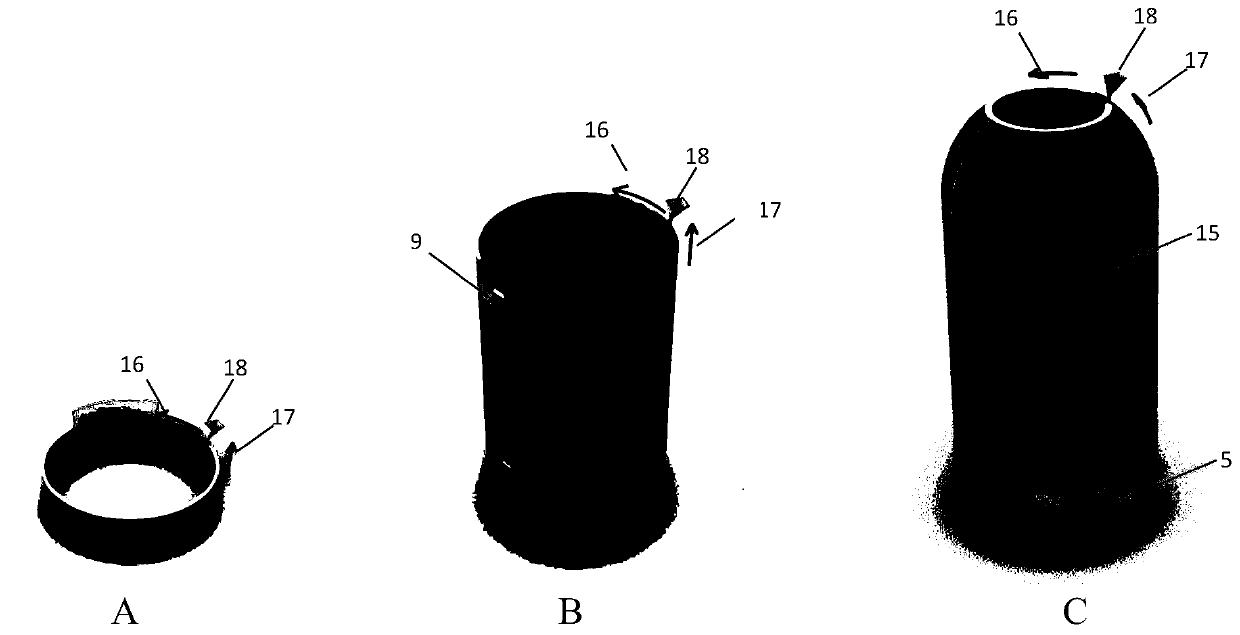

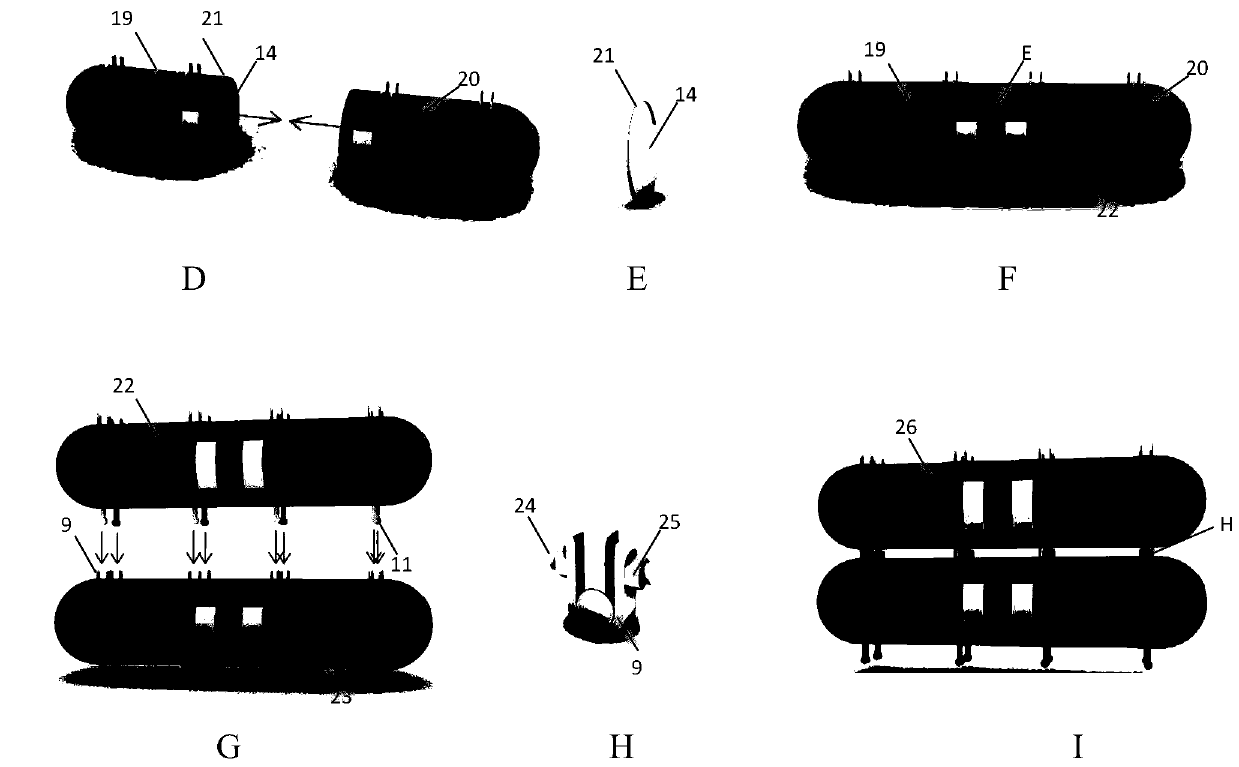

[0044] figure 1 It is a schematic structural diagram of the 3D printing negative pressure medical cabin in the embodiment. 3D printing can realize the construction of negative pressure medical cabins with various complex shapes. According to the topology optimization analysis under the combined working conditions of medical negative pressure, structural weight, equipment load and patient load, the medical negative pressure of the annular capsule cabin type is preferred in this embodiment. cabin, but is not limited to this form. This form of medical cabin has the advantages of reasonable force, smooth space, easy disinfectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com