A construction method of space aggregate reinforced 3D printed concrete structure

A concrete structure, 3D printing technology, applied in the fields of building materials, building structures and modeling design, can solve the problems of poor overall structural performance enhancement efficiency, maintaining space angle, limited bonding effect, etc., to achieve technical superiority, convenience and enhancement The overall bearing capacity and the effect of improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

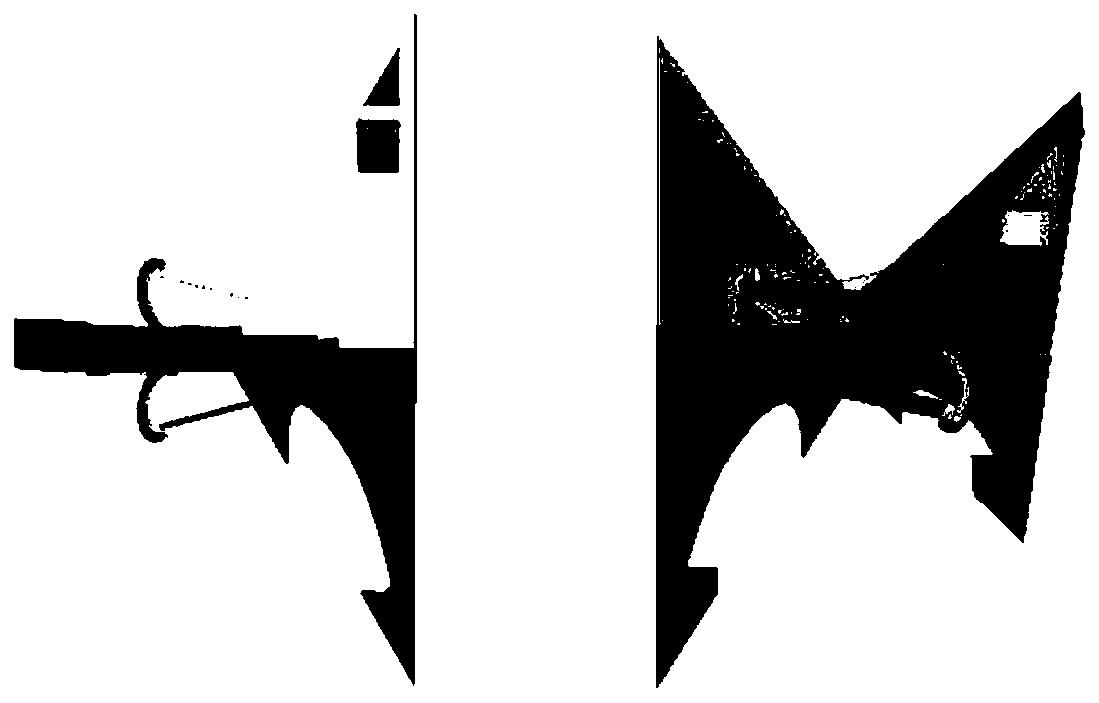

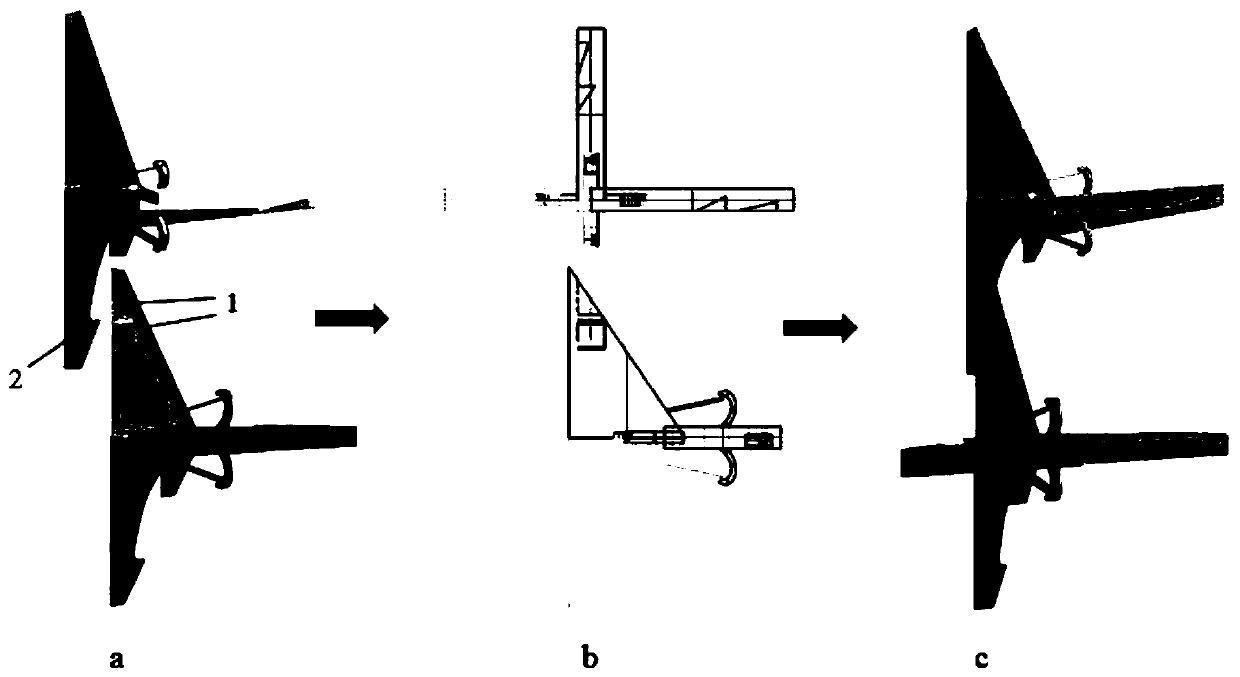

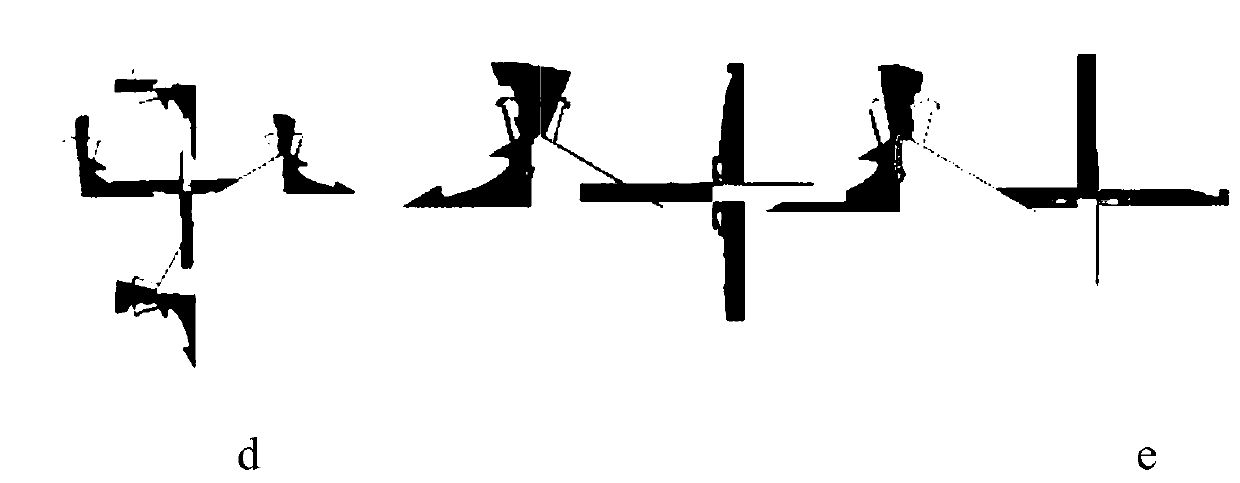

Image

Examples

Embodiment 1

[0051] Embodiment 1 Space truss girder is used as the construction method of the structural member of bridge

[0052] 1. Determine the structural form and spatial structure according to the structural and functional requirements. The main stress components of bridges are generally beam or arch structures. 3D printing cement-based materials have high compressive strength and low tensile strength. Choosing beam structures as the main stress structure of bridges can make full use of new space aggregate reinforcement. Characteristics of the tensile strength of cement-based materials. The spatial modeling of the beam structure is selected through computer topology optimization after modeling, and the optimized structural shape is used as the structural component of the 3D printed bridge.

[0053] 2. Carry out mechanical calculation and analysis on the structural components, and determine the printing weaving process and the type of space aggregates added to the structural componen...

Embodiment 2

[0058] Embodiment 2 relates to a construction method in which a circular column is a structural member of a bridge

[0059] 1. Carry out mechanical calculation and analysis on the column, and determine the printing weaving process and the type and amount of rigid aggregate added to the structural member according to the limit state of the structural bearing capacity and the selection of the limit state of normal use.

[0060] 3. Prepare 3D printing materials; according to the positioning and dosage of the selected spatial rigid aggregate, edit the electromagnetic signal and positioning push program of the spatial aggregate.

[0061] 3. According to the printing and weaving process, the 3D printing substrate is printed layer by layer. There is a mechanical arm next to the printing head to carry the new space aggregate bin, and the electromagnetic signal is edited along with the printing path. The mechanical bayonet design and electromagnetic positioning at the end are used to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com