A construction method and composite beam of composite beam integrated with 3D printing and weaving

A 3D printing and construction method technology, applied in the construction method of composite beams and the field of composite beams, can solve the problems of insufficient tensile strength and toughness, and the difficulty of printing structures to break through the space span and bearing capacity, etc., to achieve enhanced fracture toughness and impact resistance Performance, improve space spanning ability, improve tensile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

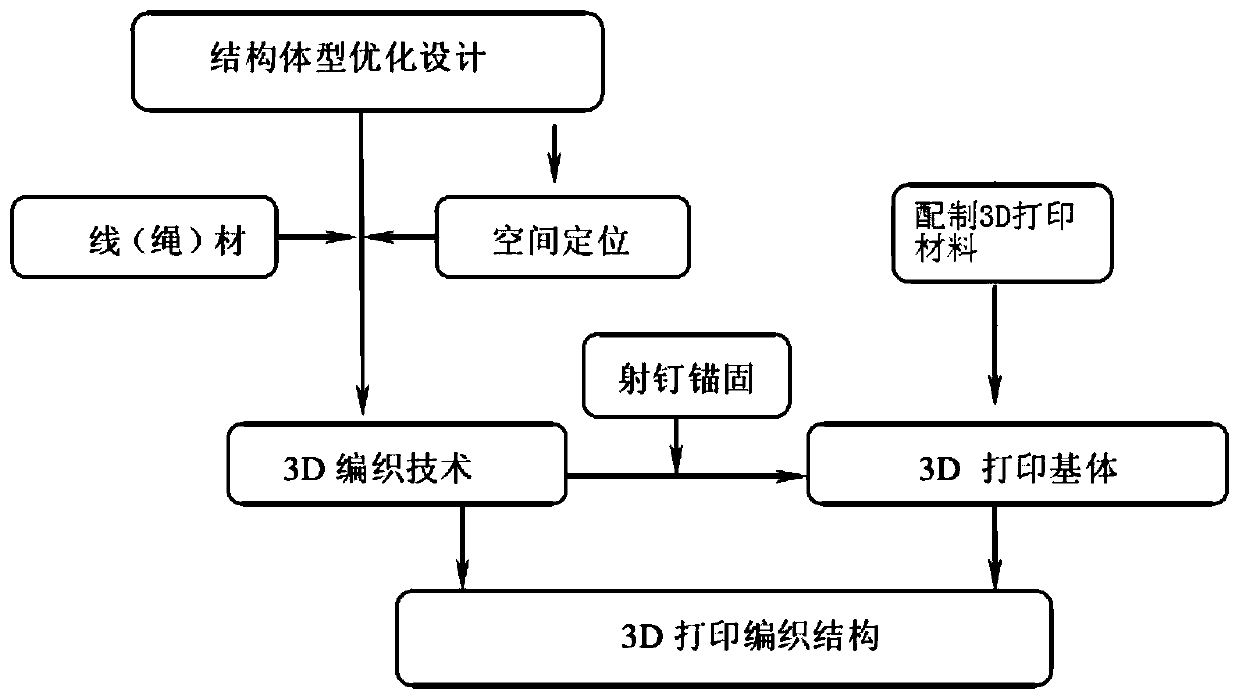

[0051] Such as figure 1 with figure 2 Shown, a kind of design and construction method of the composite beam of 3D printing weaving integrated molding, comprises the following steps:

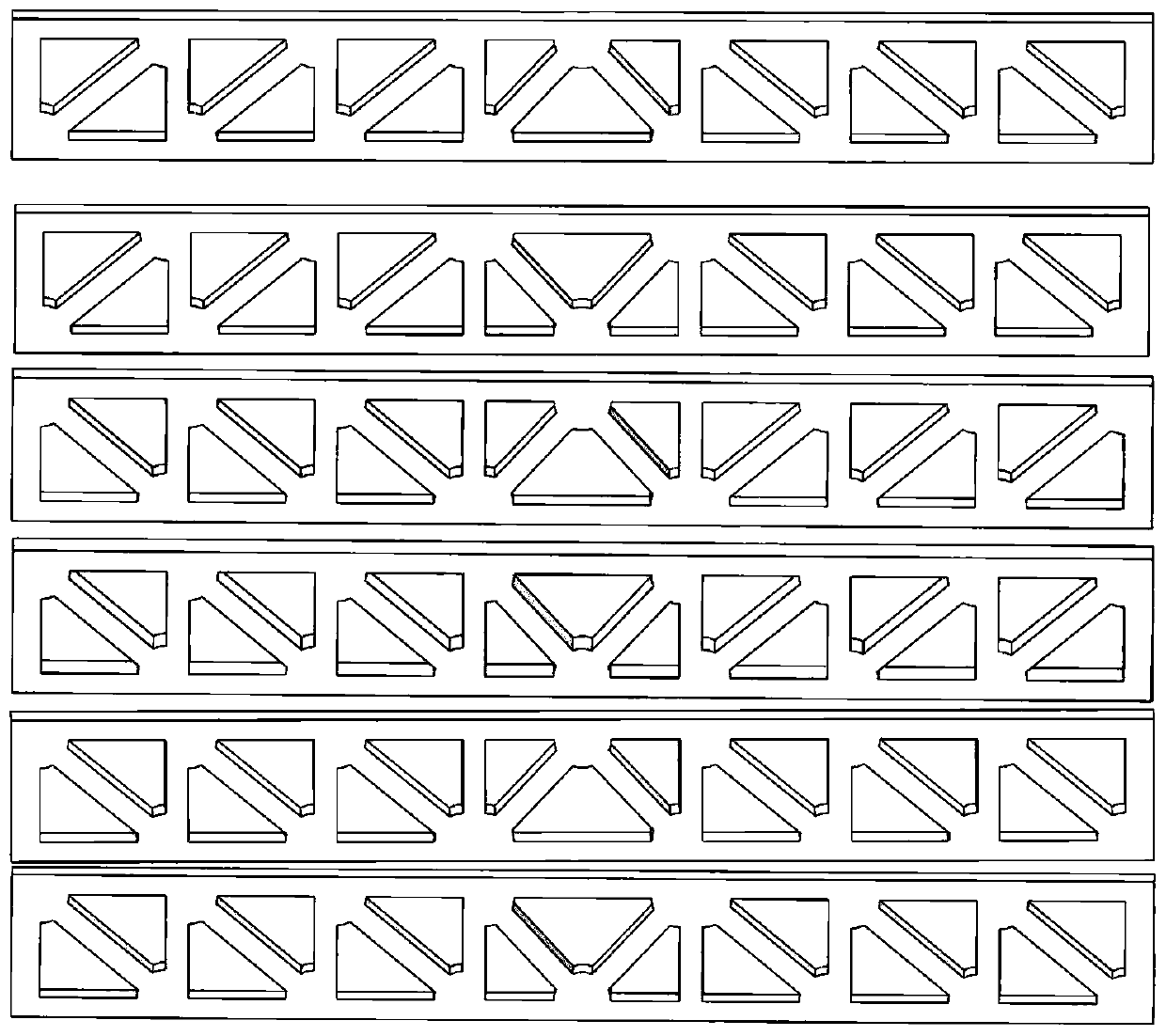

[0052] (1) Determine the beam span, beam height, and beam width. According to the hinged support state of the beam at both ends, the design value of the uniformly distributed load and the concentrated load, after the space modeling, the finite element analysis is adopted, combined with the stress cloud diagram, and the discriminant domain is set By gradually removing low-stress parts and optimizing the space shape, the design scheme of composite beam components can be initially obtained, such as image 3 shown. right image 3 The six schemes shown are calculated and analyzed. After comparing the maximum principal tensile stress and safety factor of the structure under each scheme, it is found that the maximum tensile stress of the first scheme is the smallest and the safety factor is the larg...

Embodiment 2

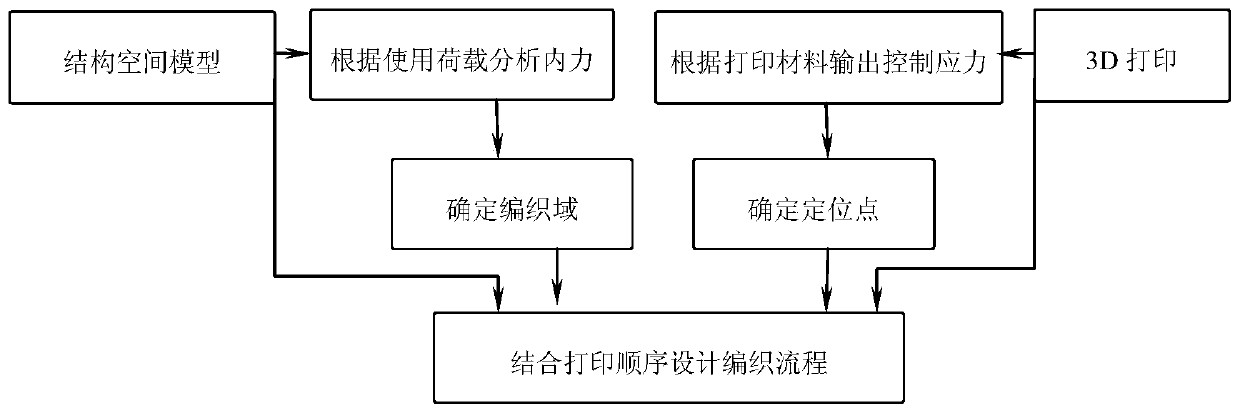

[0060] In this embodiment, weaving and weaving the external mold of the composite beam component (the external mold of the composite beam component is also called the composite beam external mold) through 3D printing, and then building steel bars and pouring concrete to obtain the composite beam, which specifically includes the following steps:

[0061] 1. Determine the beam span, beam height, and beam width. According to the hinged support state of the beam end and the design value of the load during the construction stage, determine that the area where the composite beam is prone to tensile cracking and large deformation during the construction stage is the weaving reinforcement area during printing; Determine the thickness of the outer mold of the 3D printed beam, and determine the braiding amount of the wire according to the stress of the outer mold area of the component after the load combination and the safety factor.

[0062] In this embodiment, the structure of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com