Self-restoration concrete frame column sliding node

A concrete column and concrete technology, which is applied to building components, building types, and earthquake resistance, can solve problems such as loss of energy consumption capacity, inconvenient construction of cast-in-place concrete structures, and increased difficulty in structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

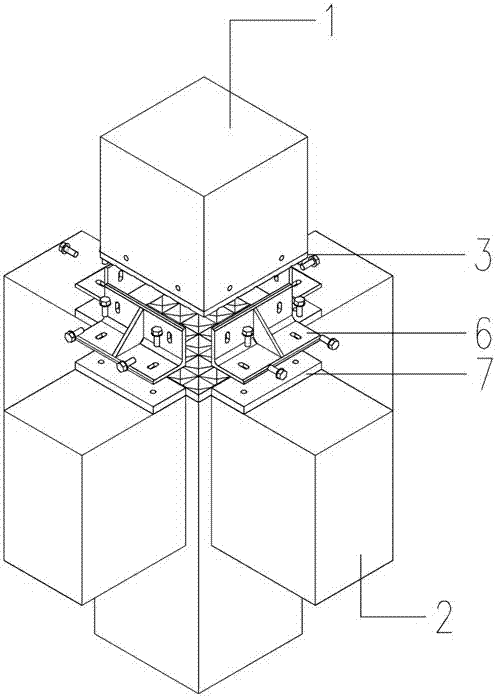

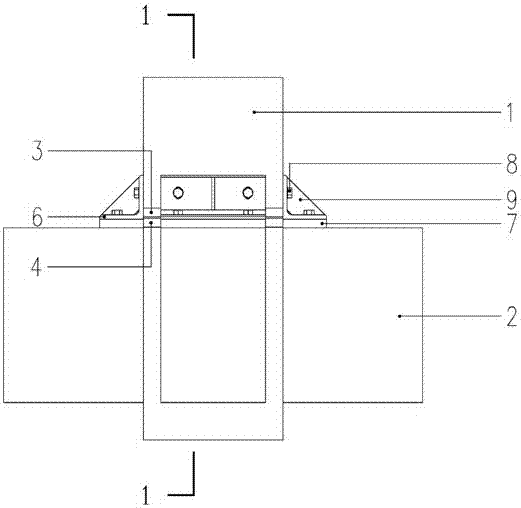

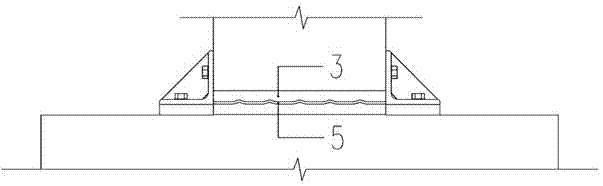

[0018] Embodiment 1: as Figure 1~3 As shown, it is an embodiment of the self-resetting concrete frame column slip joint of the present invention, including a concrete column 1, a concrete beam 2, an upper reset steel plate 3, a lower reset steel plate 4, a rubber plate 5, an angle steel 6, a viscous friction damper 7, It is composed of pressure-bearing high-strength bolts 8, stiffeners 9 and other components. The upper reset steel plate 3 and the lower reset steel plate 4 are made of high-strength steel. Can be well occluded; the rubber plate 5 is connected with the lower reset steel plate 4 to avoid uneven stress distribution; the angle steel 6 has a long hole, and a viscous friction damper 7 is installed between the angle steel 6 and the concrete beam 2, and the angle steel 6 passes through the bearing Pressed high-strength bolts 8 are connected to the embedded parts in the concrete column 1 and the concrete beam 2, and certain stiffeners 9 are added to the angle steel 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com