Internal full-height corrugated pipe prefabricated wallboard based assembly type building and construction method thereof

A technology of prefabricated wall panels and construction methods, which is applied in the direction of buildings, building components, building reinforcements, etc., and can solve the problems of large impact on the shear performance and seismic performance of wall panels, high requirements for alignment accuracy of steel bars, and poor controllability of construction quality To achieve the effect of convenient and efficient construction method, strong controllability of construction quality and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

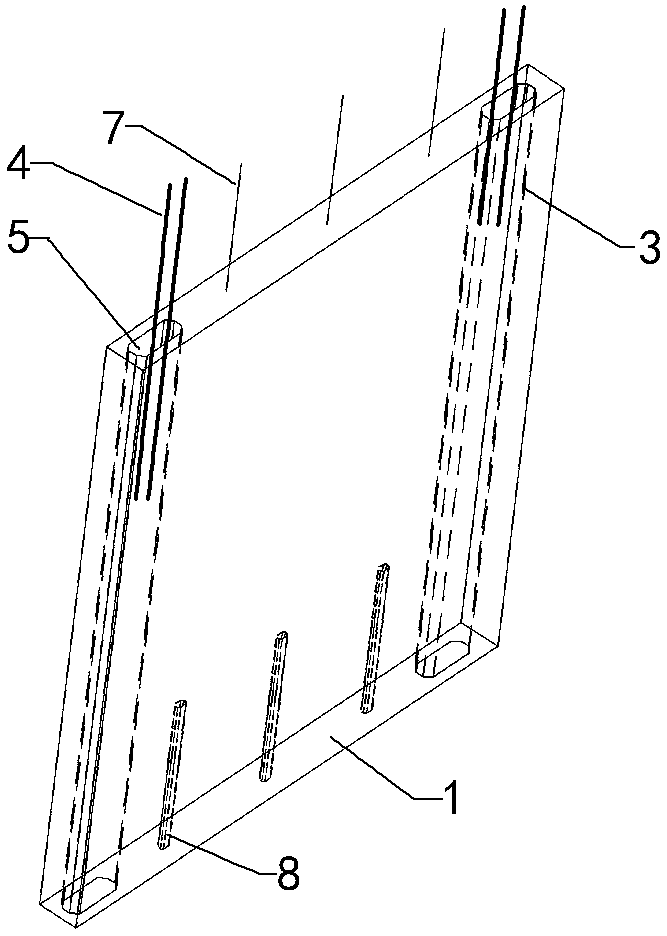

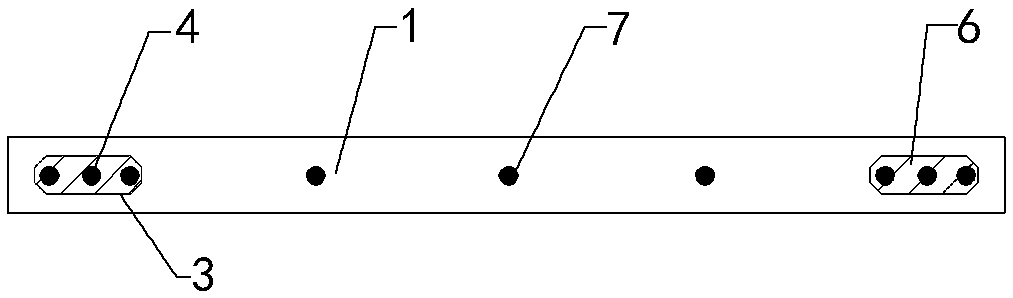

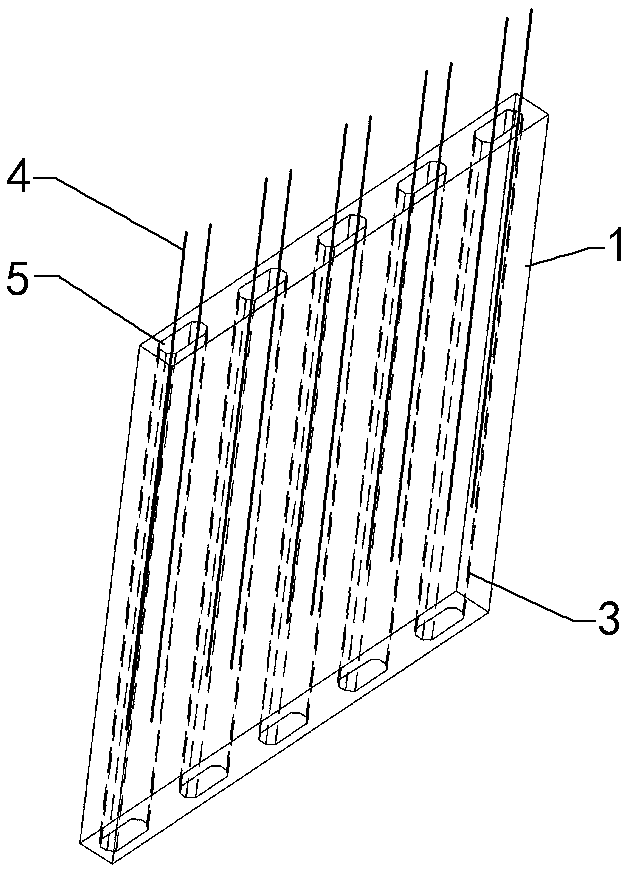

[0053] Such as Figure 1 to Figure 6 As shown, the present invention is based on a prefabricated building of prefabricated wall panels with built-in full-height bellows, including floor slabs 2 and prefabricated wall panels 1 arranged between adjacent floor slabs 2, upper prefabricated wall panels 12 and lower floor prefabricated wall panels 11 is connected through connecting piece 4.

[0054] A joint slurry layer 9 is arranged between the lower end surface of the prefabricated wall panel 1 and the upper surface of the floor slab 2. The thickness of the joint slurry layer 9 is not less than 3 mm, preferably 20 mm. The joint slurry can be laid in advance or the prefabricated wall panel 1. Set up the filling after it is in place. The joint slurry can be grouting material or sitting slurry.

[0055] Such as image 3 and Figure 4 As shown, the prefabricated wallboard 1 is pre-embedded with bellows 3, the number and location of the bellows 3 can be flexibly selected and adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com