Factorial construction method for component of total prefabricated assembly integral type shear wall structure system

A prefabricated assembly and integrated technology, which is applied in building structure, mold, construction, etc., can solve the problems of environmental protection and high construction cost, and achieve the effects of high overall assembly rate, reduced waste generation, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

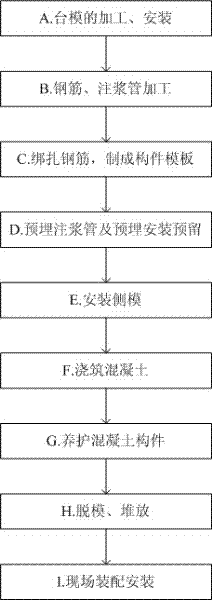

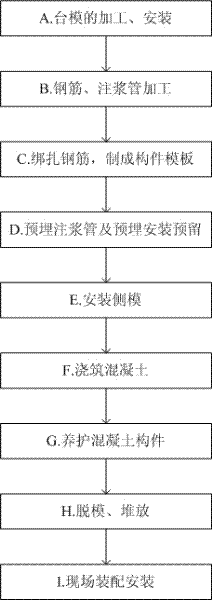

[0021] figure 1 Shown is a schematic flow chart of a preferred embodiment of the component preparation method of the prefabricated shear wall system of the present invention. As shown in the figure, the preparation method of this embodiment includes the following steps:

[0022] A. Formwork processing and installation:

[0023] The panel of the table form is made of 8mm thick steel plate, the back flute main keel of the table form is made of 40a I-beam, and the auxiliary keel of the table form is made of U-shaped steel of 80×80mm and 3mm thick. In order to ensure the welding quality and the flatness of the table mold surface, argon arc welding is used during welding, and the seams of the steel plates should be chamfered. The surface of the weld seam should be uniform, smooth, and free of wrinkles. Defects such as burn-through, arc craters, needle-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com