Pipeline installing method

An installation method and pipeline technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problem of increasing the work intensity and safety risk factor of workers, increasing the workload of the construction site, and increasing the number of hoisting. and other problems, to achieve the effect of improving the integrity and resistance to uneven settlement, reducing the lifting weight and reducing the amount of pouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

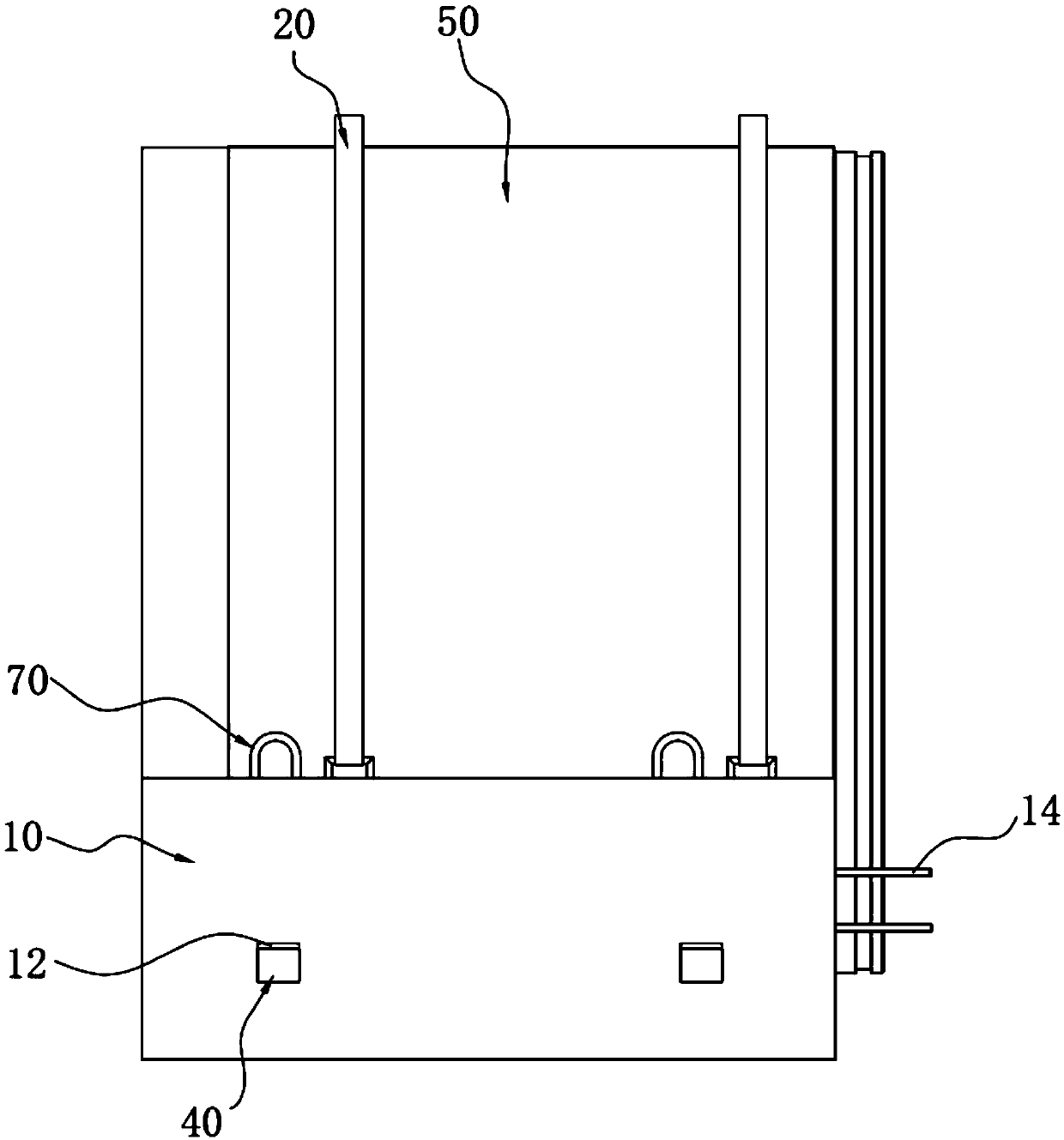

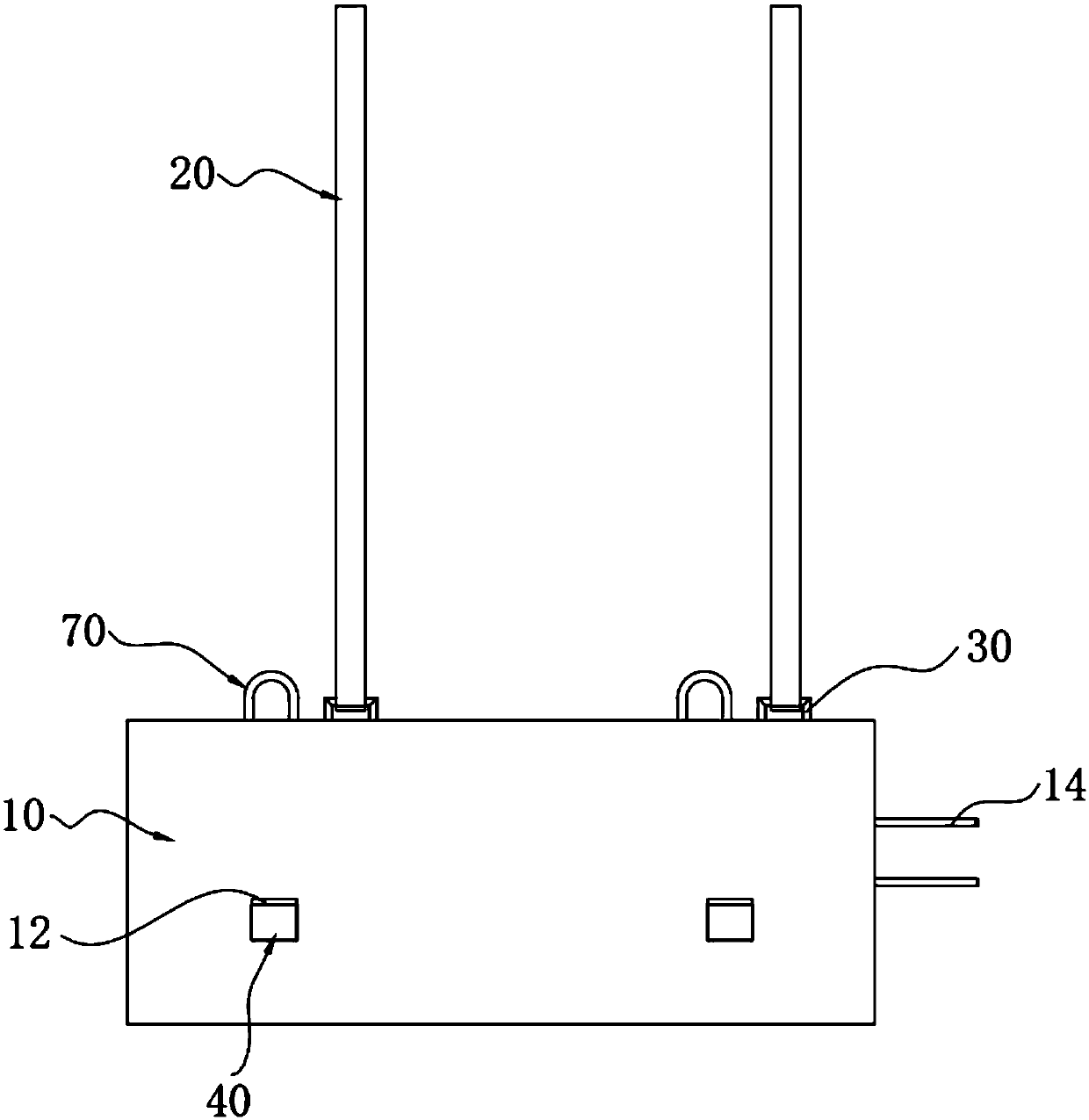

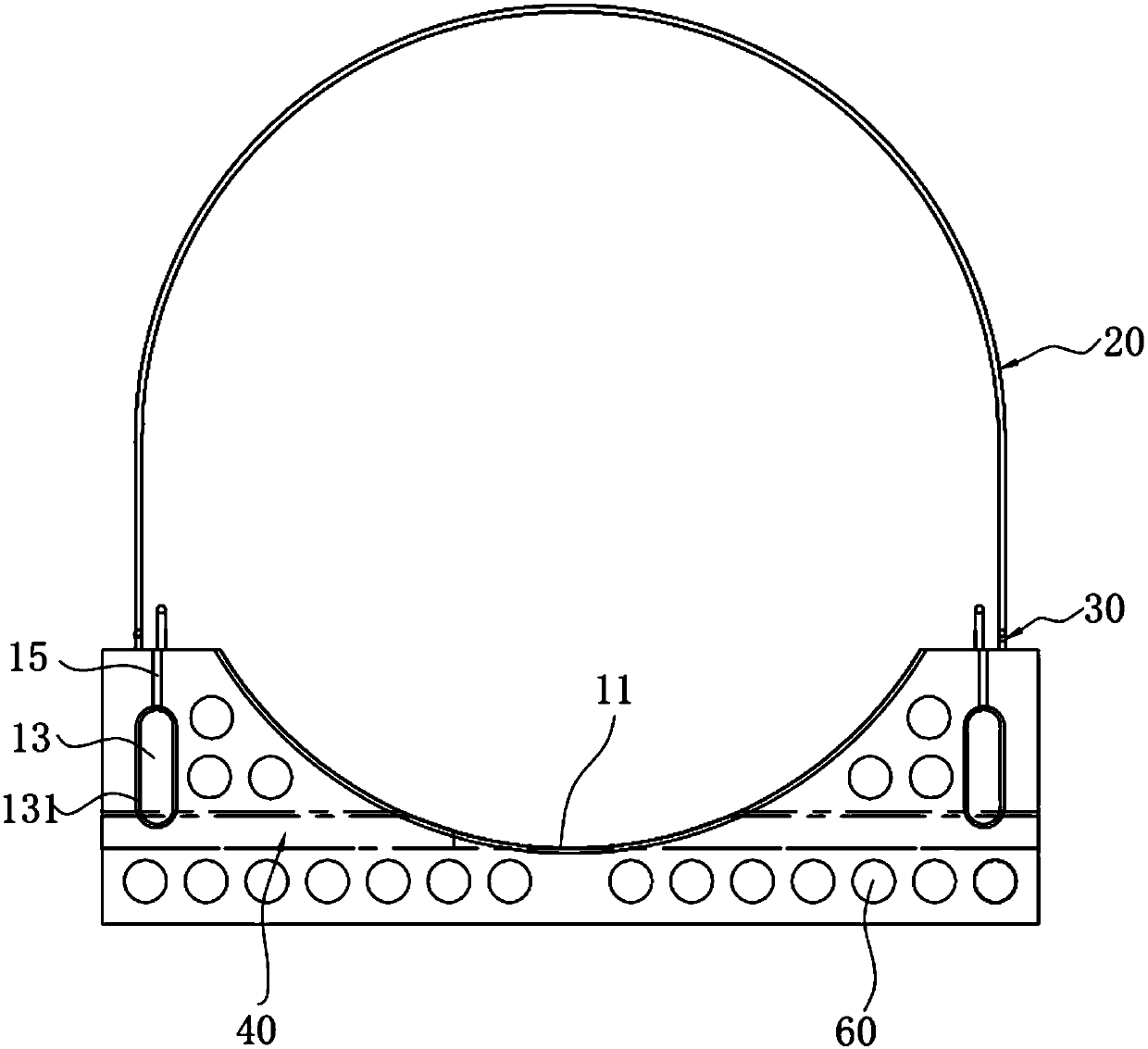

[0034] In the present invention, the structure of each pipe-based pipe joint unit is the same. In the embodiment, only for the convenience of illustration, the first installed pipe-based pipe joint unit is named the first pipe-based pipe joint unit, and the second installed pipe-based pipe joint unit is named as the first pipe-based pipe joint unit. The node unit is named as the second pipe-based pipe-section unit, and so on. Taking the first pipe-base pipe-section unit as an example, the structure of the pipe-base pipe-section unit is described in detail. Such as figure 1 As shown, the first pipe base pipe section unit includes the first pipe base 10, the first pipe section 50 and the fastening belt 20; as Figure 2 to Figure 4 As shown, the first tube base 10 is formed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com