Assembly type precast light floor

A prefabricated and floor-slab technology, applied to floors, building components, buildings, etc., can solve problems such as low construction efficiency, poor concrete adhesion, and difficulty in ensuring overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. The embodiments described below with reference to the accompanying drawings are examples and are intended to explain the present invention, but should not be construed as limiting the present invention.

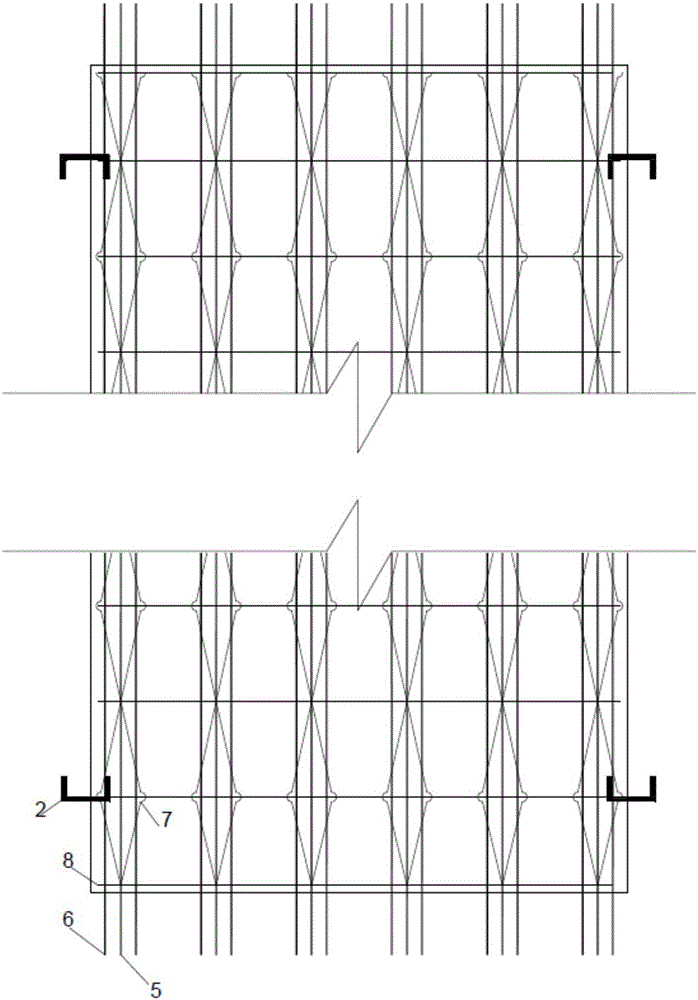

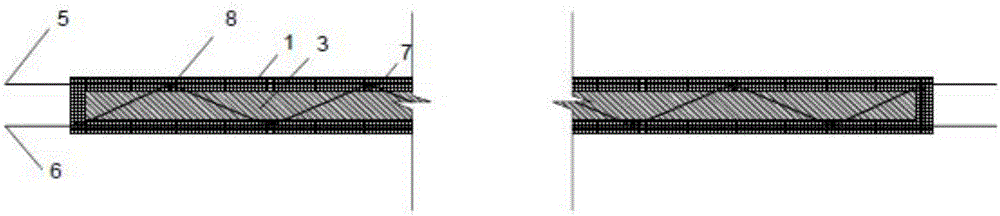

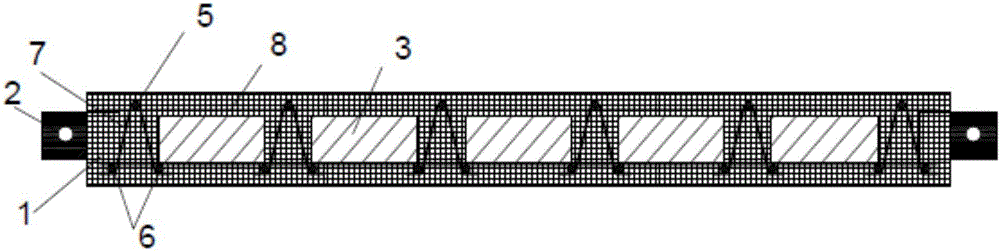

[0022] as attached figure 1 - attached Figure 4 As shown, the present invention is completed in one pouring in the factory. In the factory, the upper chord steel bar (5), the lower chord steel bar (6) and the obliquely bent steel bar (7) are welded to form a steel bar truss (4), and the connecting channel steel (2) is welded and connected with the upper and lower horizontally distributed steel bars (8), and then the light weight is completed. Firstly, the precast concrete layer (1) and the lower part of the concrete are poured first. When it is not yet solidified, the lightweight material plate (3) is fixed in the middle of the steel truss (4), and then horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com