Method for building gravity dam on deep and thick cover layer and spandrel concrete gravity dam structure

A technology of deep overburden and concrete, applied in gravity dams, dams, etc., can solve the problems of high technical difficulty and high engineering cost, and achieve the effect of good application prospects, reduction of engineering investment, and reduction of foundation excavation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

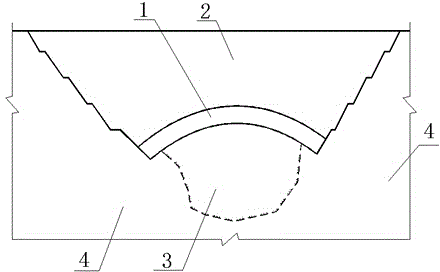

[0011] like figure 1 As shown, the concrete gravity dam structure on the arch of the present invention includes a bottom arched concrete base 1 and a gravity dam 2 arranged on the arched concrete base 1, and the arch ends of the arched concrete base 1 are arranged on the bedrock 4 on both banks. The bottom of the concrete base 1 is arranged on the steep and deep covering layer 3 , the two ends of the gravity dam 2 are arranged on the bedrock 4 on both banks, and the bottom of the gravity dam 2 is arranged on the arched concrete base 1 .

[0012] Among them, the excavation slope ratio of bedrock 4 is 1:0.1~1:0.5. The deep covering layer 3 adopts dynamic compaction treatment, consolidation grouting treatment or other foundation treatment; the arch concrete base 1 arch is poured in a parabola, concentric circle, two-center circle, three-center c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com