Assembly type spherical hollow plate

A hollow slab and prefabricated technology, which is applied to floor slabs, building components, ceramic forming machines, etc., can solve the problems of large amount of secondary concrete pouring, large amount of concrete pouring on site, and small thickness of prefabricated laminated slabs, so as to save support The reduction of materials, construction personnel and equipment, and the effect of reducing the amount of on-site concrete pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

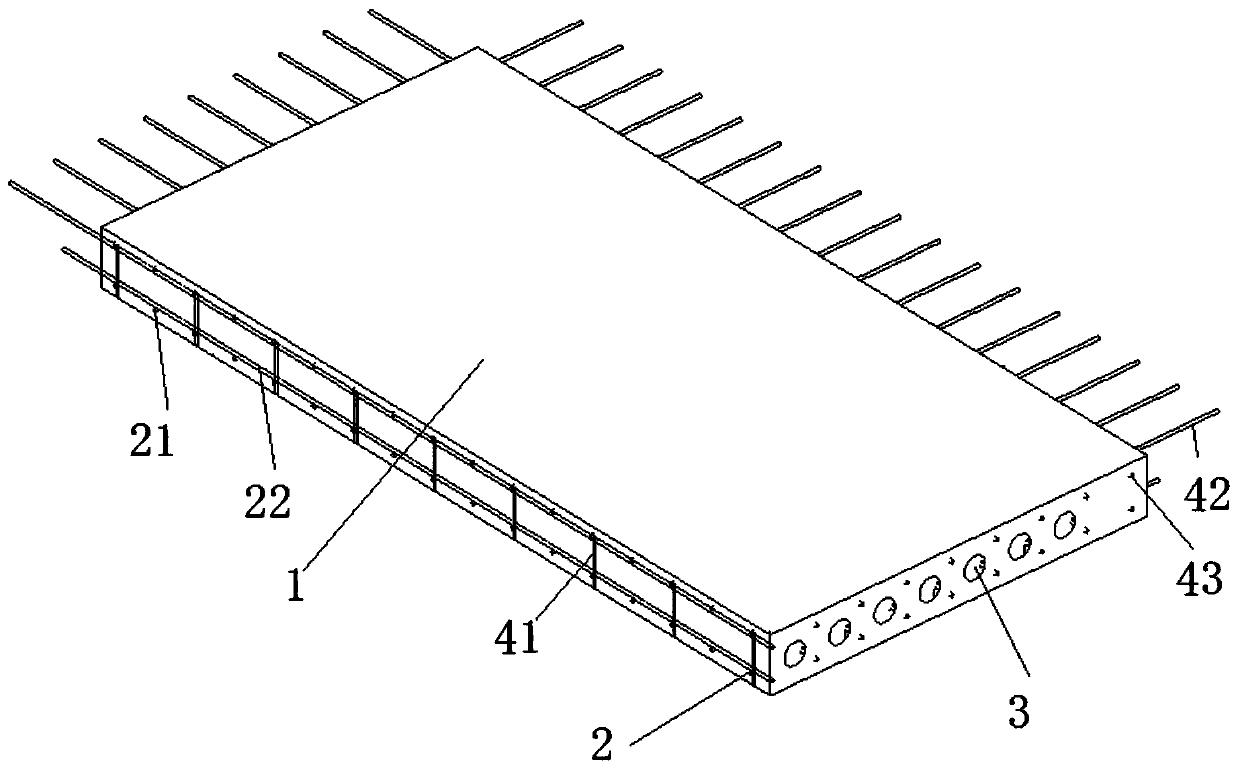

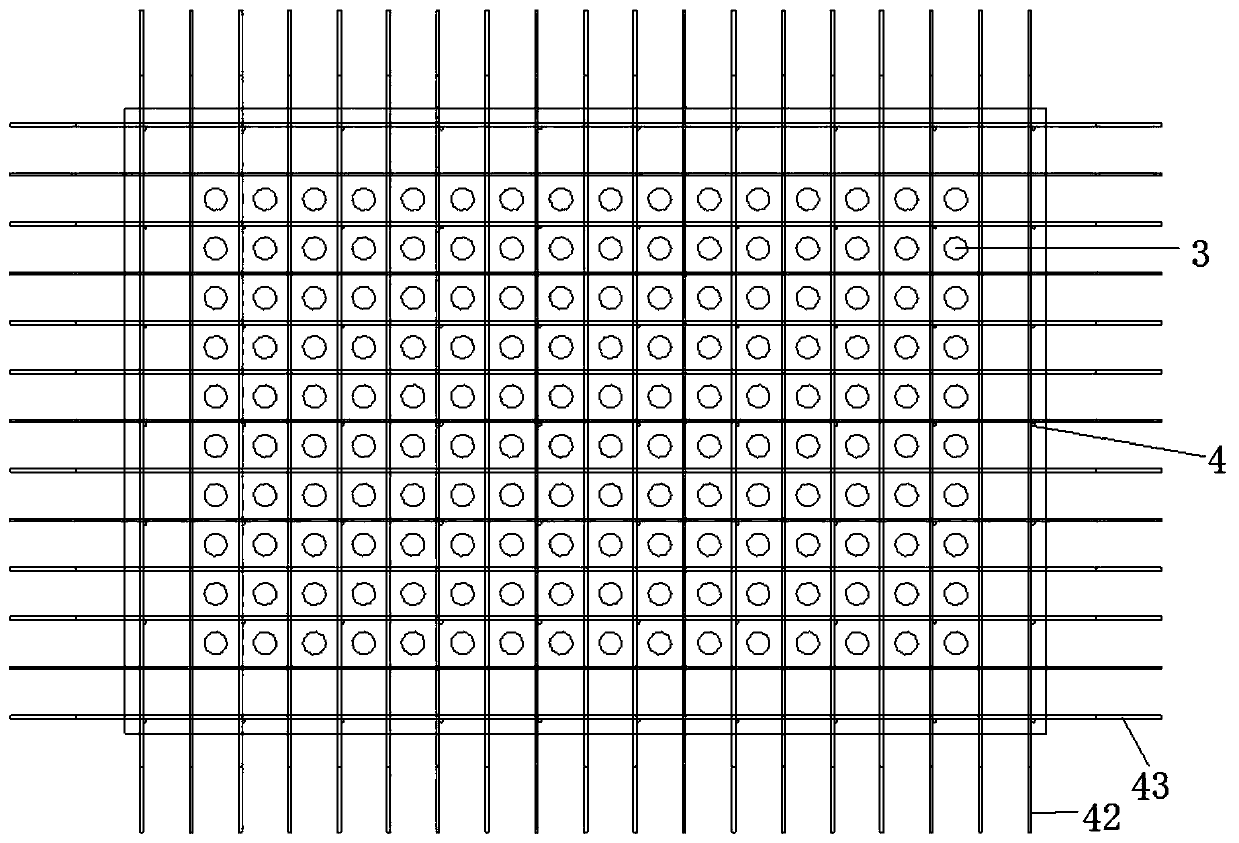

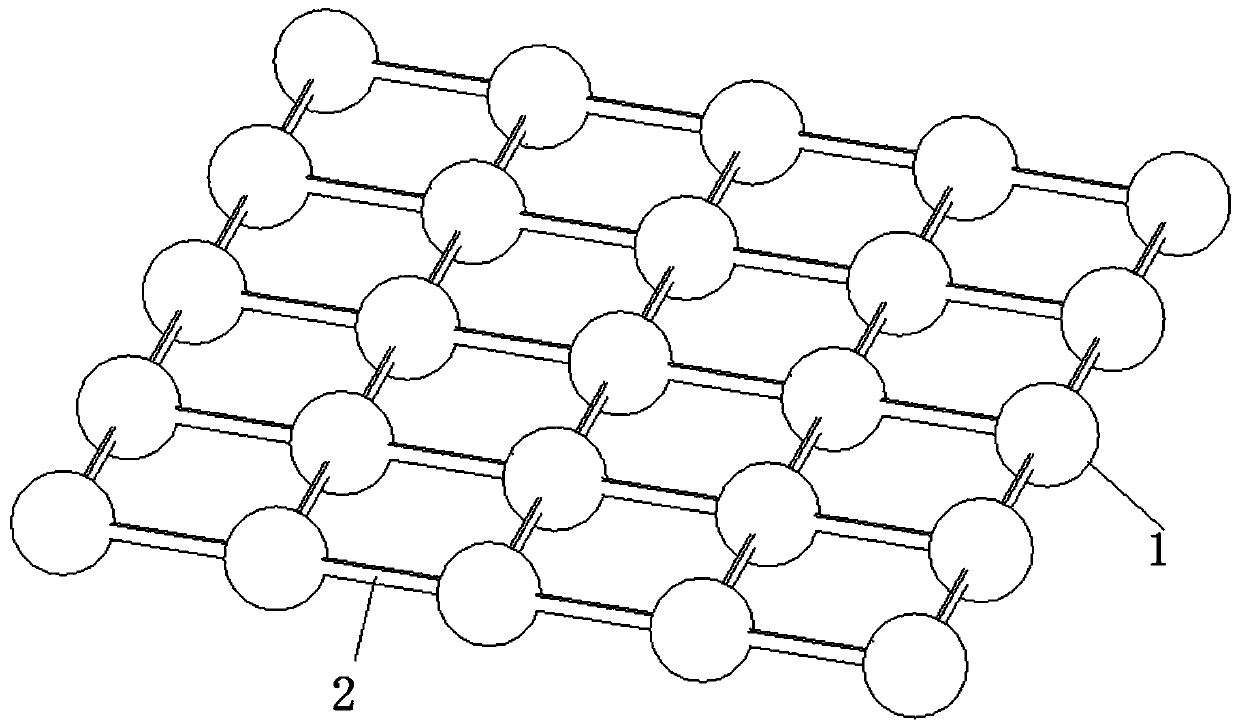

[0030] combined with Figure 4 , in order to further optimize the above-mentioned technical solution, another embodiment 2 of the hollow spherical member 3 includes hollow balls 31 and steel mesh 32, the hollow balls 31 are distributed on the steel mesh 32 in a matrix; the steel mesh 32 is formed by the hollow spherical member through Consisting of reinforcing bars 321 and hollow spherical member latitudinal reinforcing bars 322, a plurality of hollow spherical member latitudinal reinforcing bars 322 are arranged in parallel, the hollow spherical member latitudinal reinforcing bars 322 pass through the spherical center of the hollow ball 31, and the hollow ball 31 is fixed on the hollow ball On the component latitudinal reinforcing bars 322; multiple hollow spherical component meridian reinforcing bars 321 bypass the hollow spherical component meridian reinforcing bars 322 up and down sequentially, and the multiple hollow spherical component meridional reinforcing bars 321 inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com