Foundation structure of steel tower

A foundation and iron tower technology, applied in the field of iron tower foundation structure, can solve the problems of more time and labor required for construction, more concrete pouring, and larger labor load, etc., to achieve labor costs, scale reduction, and excavation reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

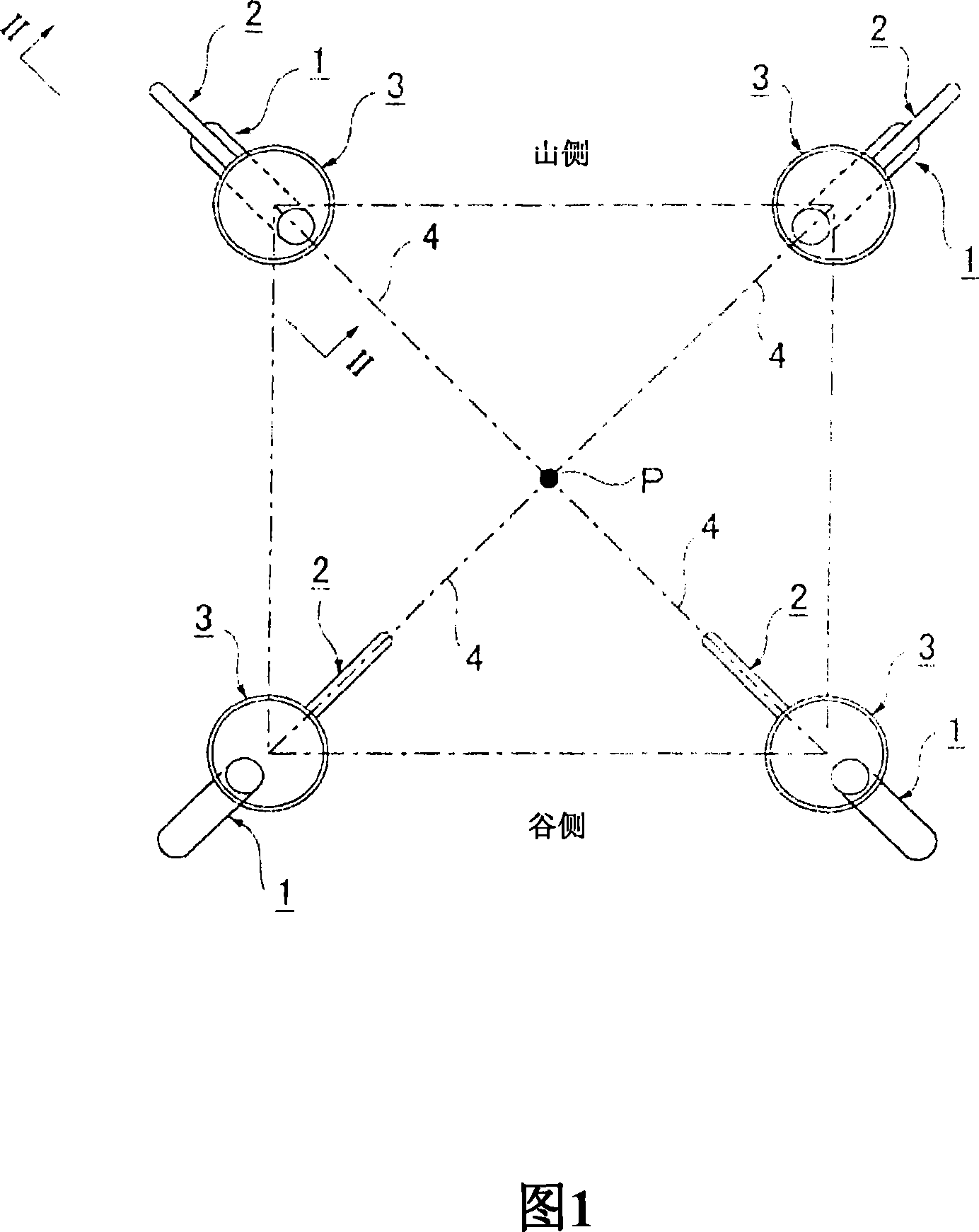

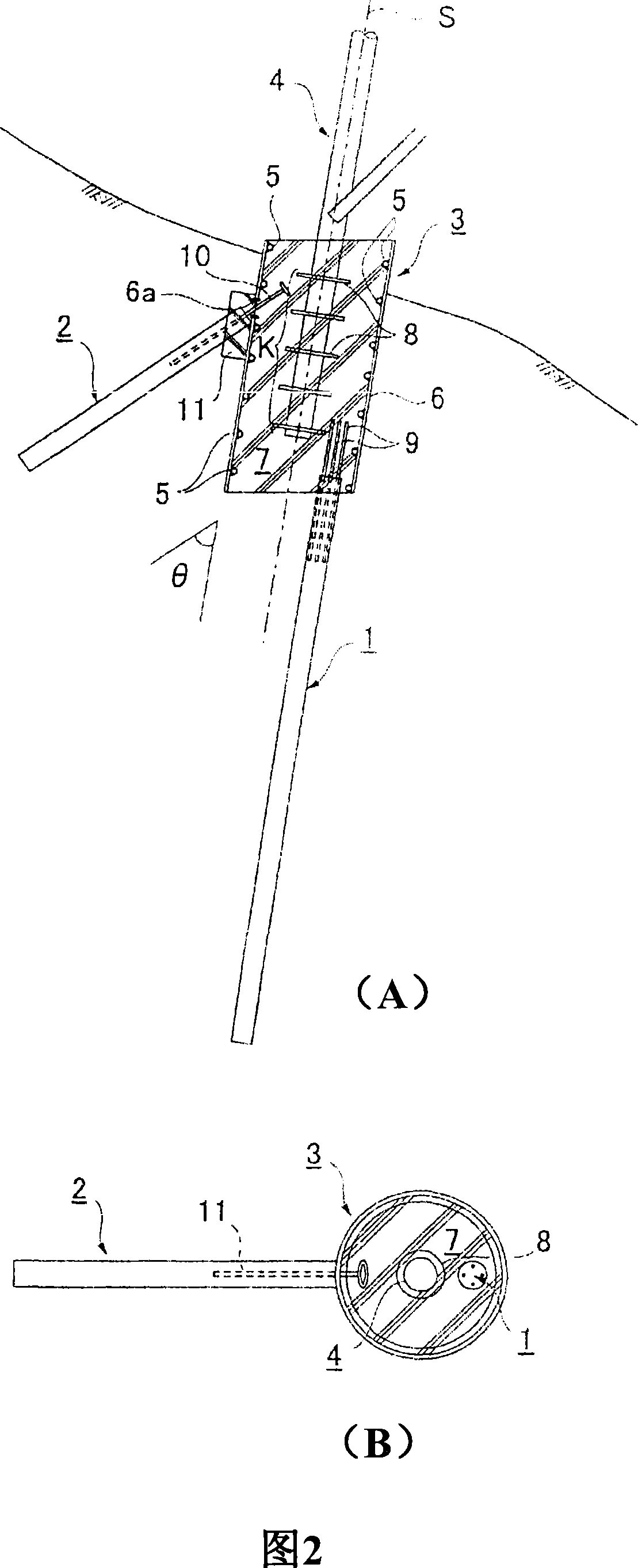

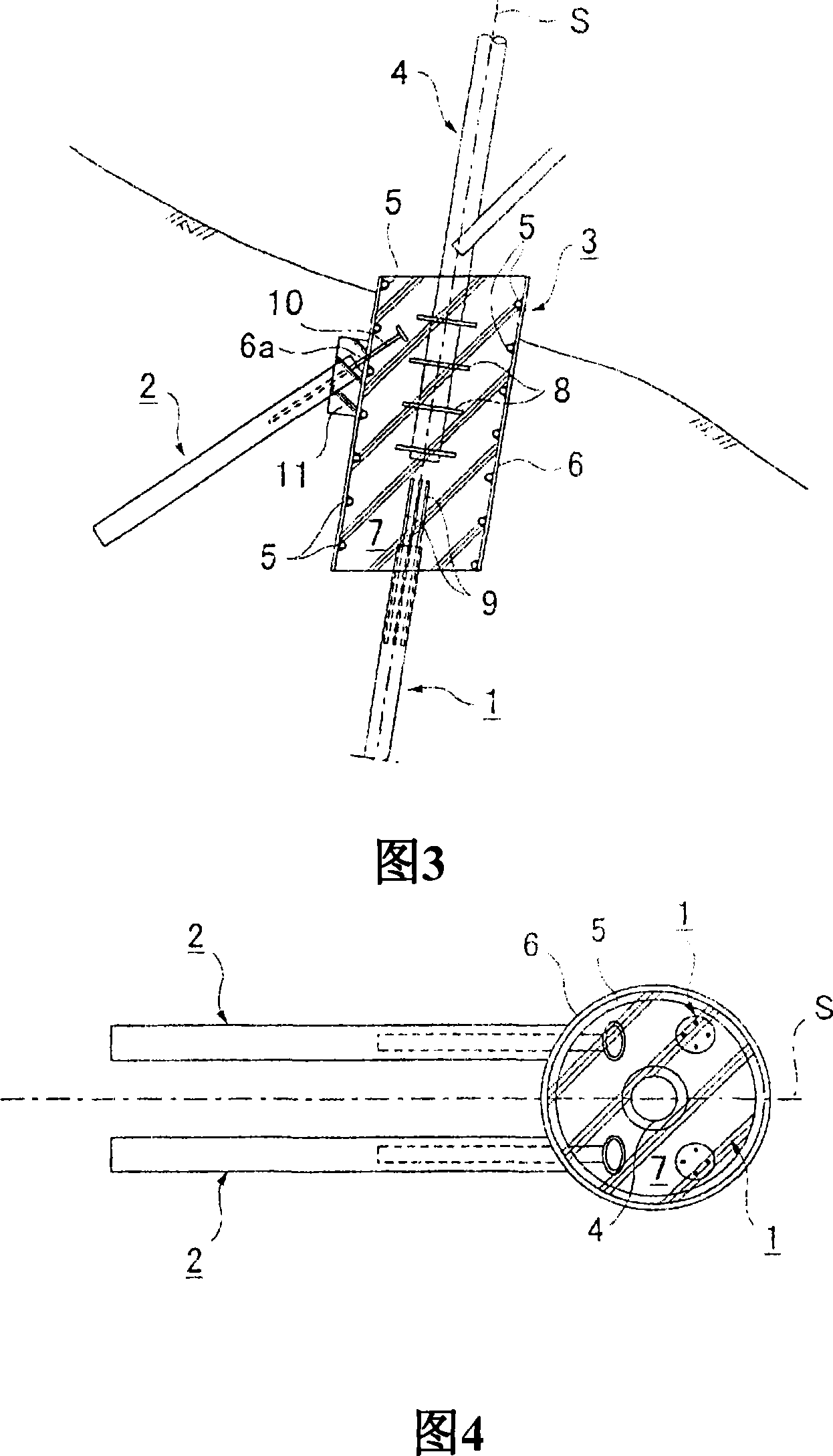

[0077] As shown in Figures 1 and 2, the iron tower foundation structure of the present invention includes: one or more main piles 1 arranged in the foundation along a direction roughly consistent with the direction S of the above-mentioned main pile 4; The plane direction of the foundation and the tower center P is set in one or more auxiliary piles 2 in the foundation; and the combination structure 3 combining the above-mentioned main pile 1 and the auxiliary pile 2 and fixing the base of the above-mentioned main pile 4 .

[0078] Described in more detail below.

[0079] As the concrete structure 3, a structure composed of thick-walled steel pipe 6 with a diameter of about 1000 to 5000 mm and a thickness of about 20 to 30 mm and concrete 7 poured into the steel pipe 6 is preferably used.

[0080] On the inner wall surface of the above-mentioned steel pipe 6, the shear flanges 5, 5... fixedly arranged along the circumferential direction are arranged in multiple stages along th...

Embodiment

[0096] Next, various tests were conducted in order to verify the effect of the combined pile group of the present invention and the dynamics of piles when a load acts.

[0097] (1) Displacement characteristics of combined pile groups

[0098] In the actual site, as shown in Fig. 9, the beam 20 is fixed by the reaction piles 21 and 21, the foundation composed of the main pile 1 and the auxiliary pile 2 is pulled out by the jack 22, and the displacement in the X-Y direction is investigated. As a result, as shown in FIG. 10 , while displacement occurs in the vertical direction, the auxiliary pile 2 is displaced in a substantially vertical direction.

[0099] (2) Displacement

[0100] In the same field test, as shown in Figure 11, the displacement in the load direction is taken as the horizontal axis, and the displacements in each case of the single pile and the combined pile group are compared. As a result, it became clear that the combined pile group can suppress displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com