Construction method drive type major diameter steel pipe pore-creating filling pile

A construction method and cast-in-situ pile technology, which can be applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of mechanical hole depth limitation, low operation safety, and non-environmental protection, so as to save engineering cost and ensure safe and reliable structure , the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The construction method of the driven-in large-diameter steel pipe hole-forming pile,

[0028] The first step is to form a hole: use a large steel pipe with an outer diameter of 2000mm without a steel tip to form a hole, and use a crawler-type diesel pile driver equipped with a guide rod piling hammer and a barrel-type piling hammer to hammer the large steel pipe;

[0029] The second step is to install the reinforcement cage: after taking out the soil in the large steel, install the reinforcement cage in the above-mentioned large steel pipe;

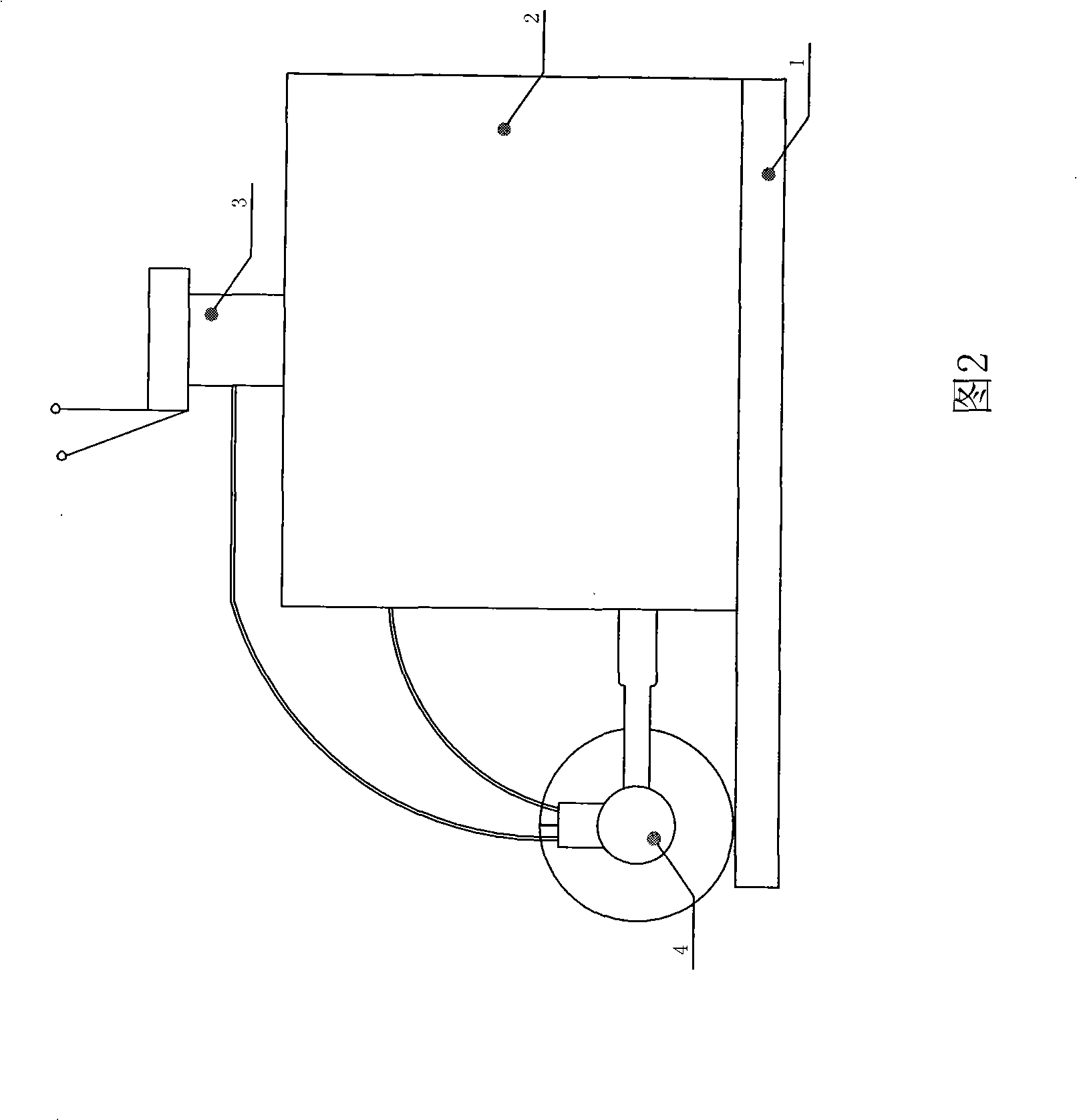

[0030] The third step of pouring: After the installation is completed, concrete is poured into the hole of the reinforcement cage and vibrated. As the concrete is poured and compacted, a hydraulic extubation device is used to extubate. It consists of a hydraulic system and an extubator. The hydraulic system is shown in Figure 2. , the hydraulic oil tank 2 is fixed on the support 1, the oil outlet of the hydraulic oil tank has an o...

Embodiment 2

[0032] Construction method of large-diameter steel pipe perforated pile,

[0033] The first step is to form a hole: use a large steel pipe with a steel pipe outer diameter of 800mm and a prefabricated concrete conical pile tip to form a hole, and use an electro-hydraulic pile driver equipped with a guide rod piling hammer and a barrel piling hammer to hammer the large steel pipe;

[0034] The second step is to install the reinforcement cage: install the reinforcement cage directly in the above-mentioned large steel pipe;

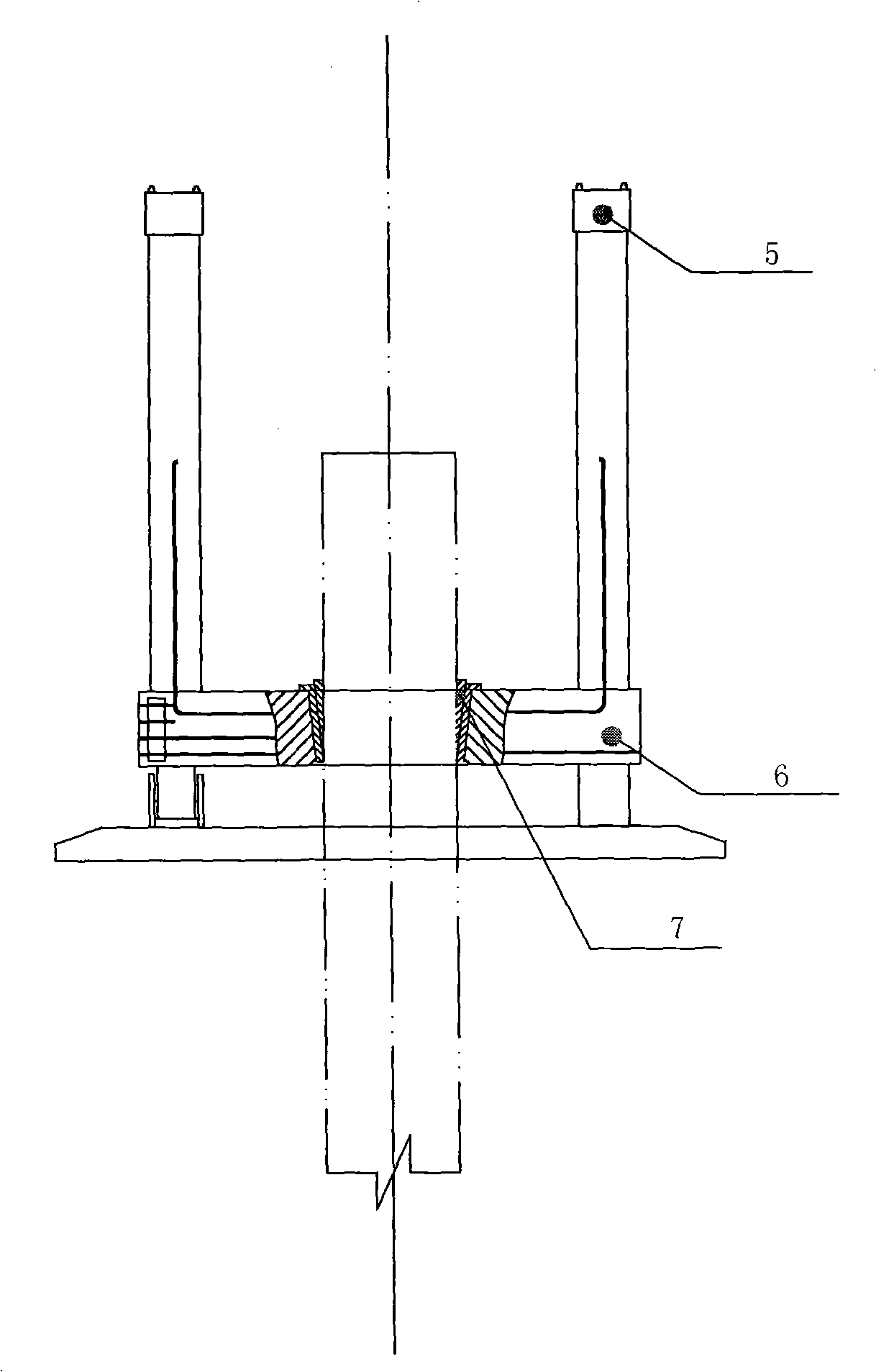

[0035] The third step of pouring: After the installation is completed, concrete is poured into the hole of the reinforcement cage and vibrated. As the concrete is poured and compacted, the hydraulic pipe removal device is used to remove the pipe. The hydraulic pipe removal device is composed of a hydraulic system and a pipe puller. The hydraulic system The arm of the hydraulic cylinder is equipped with an extubation stand, which has an assembly hole, and is ...

Embodiment 3

[0037] Construction method of large-diameter steel pipe perforated pile,

[0038] The first step is to form a hole: use a large steel pipe with an outer diameter of 1000mm and a prefabricated reinforced concrete conical pile tip to form a hole, and use an electro-hydraulic pile driver equipped with a guide rod piling hammer and a barrel piling hammer to hammer the large steel pipe;

[0039] The second step is to install the reinforcement cage: install the reinforcement cage directly in the above-mentioned large steel pipe;

[0040] The third step of pouring: After the installation is completed, concrete is poured into the hole of the reinforcement cage and vibrated. As the concrete is poured and compacted, a hydraulic oil cylinder is used to pull out the large steel pipe that forms the hole and form a pile. The diameter of the pile can reach 1000mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com