Forging process of external star wheel provided with handle

A technology of extraterrestrial wheels and craftsmanship, applied in the field of forging, can solve problems such as easy cracks on the surface of forgings, difficulty in maintaining consistent temperature of forgings, uneven thermal expansion and cold contraction of forgings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0044] The present invention will be further described in detail below in conjunction with the drawings.

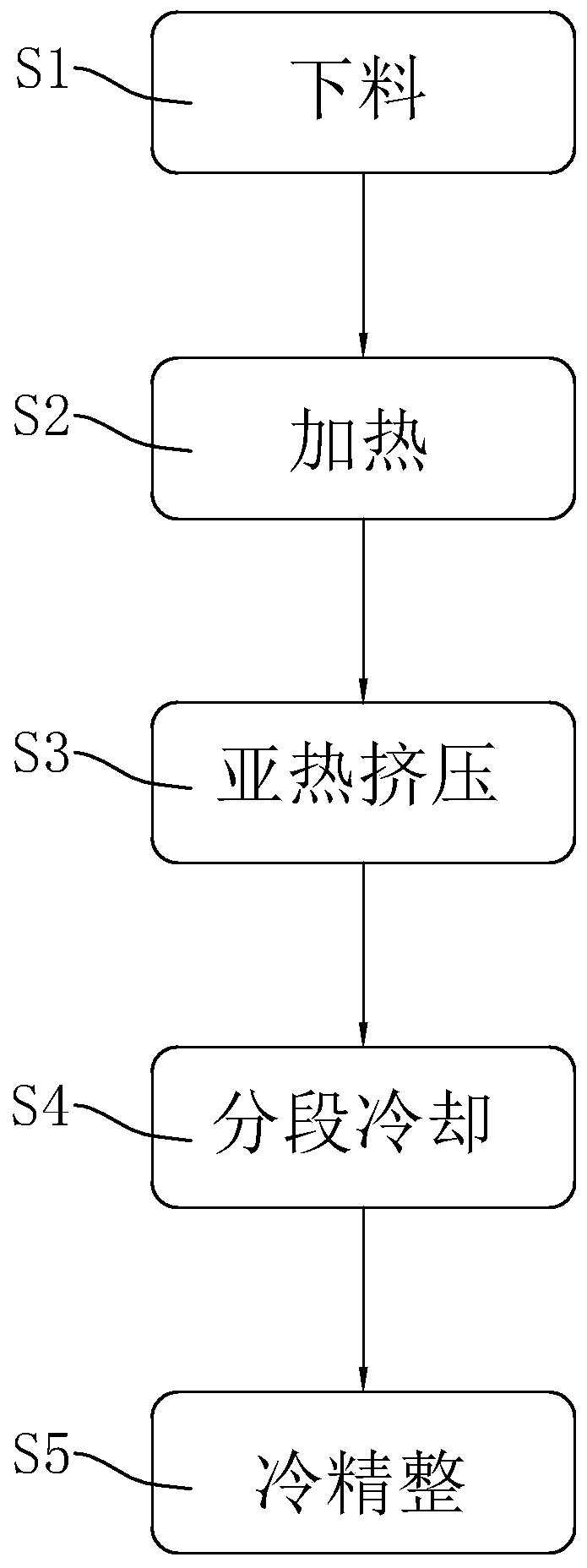

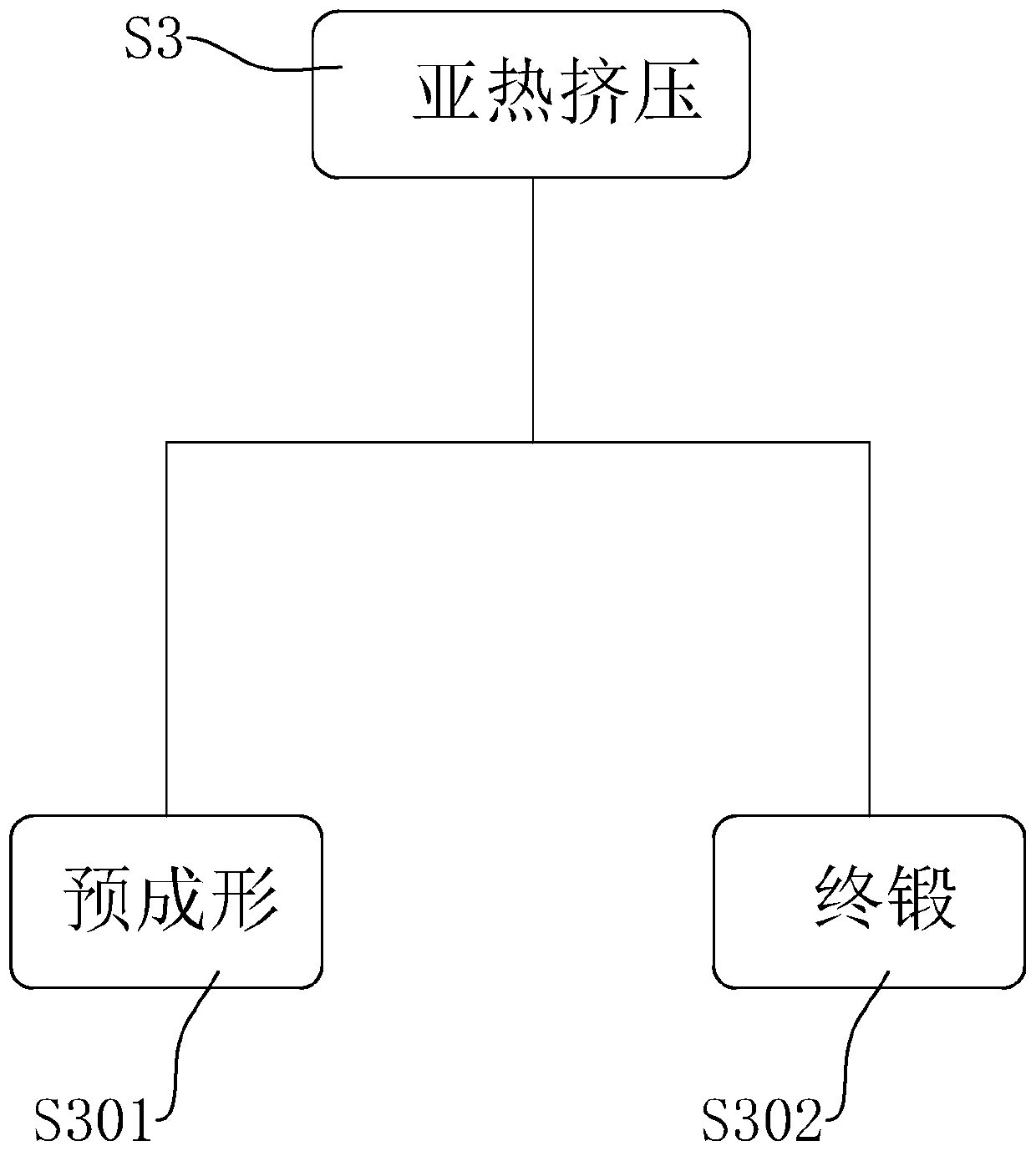

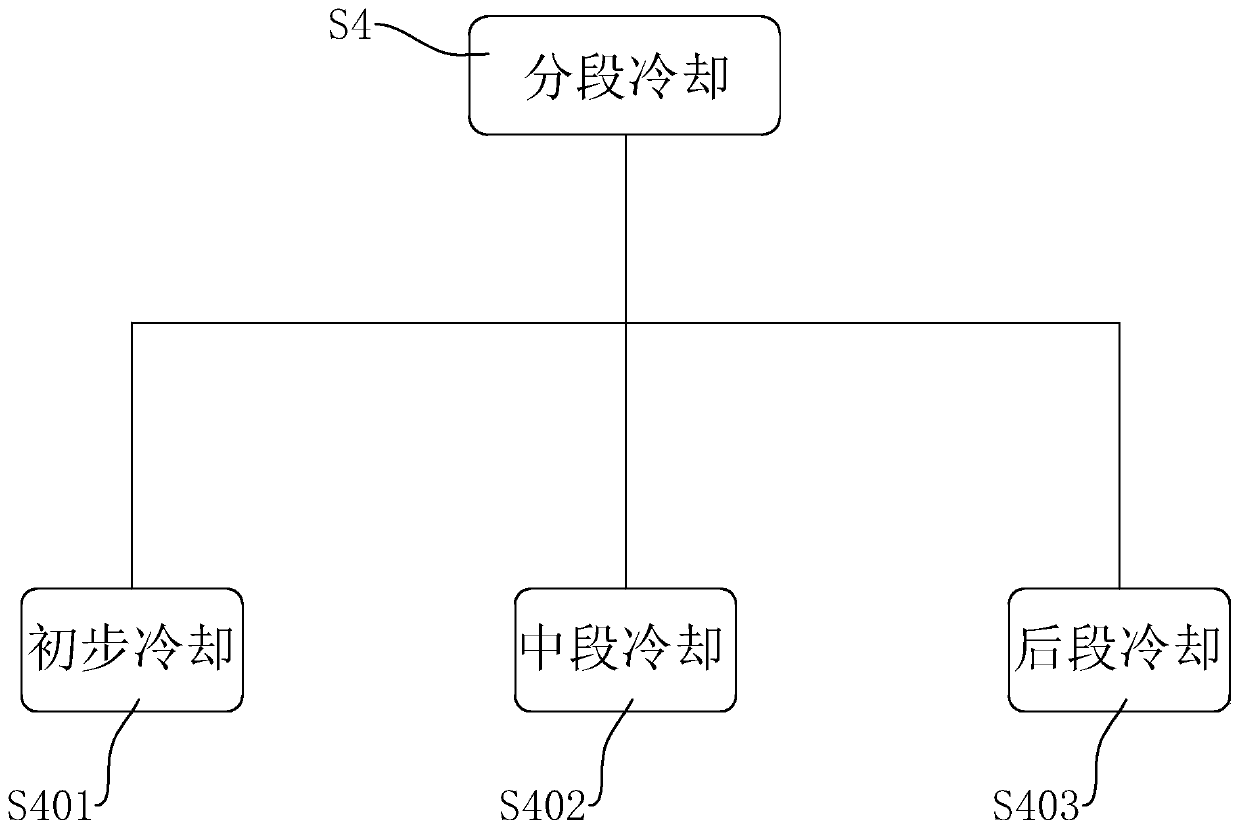

[0045] Reference figure 1 , Is a flow chart of the forging process of a shank alien wheel in the embodiment of the present invention, figure 2 The specific flow chart of the sub-hot extrusion of the blank in the embodiment of the present invention, image 3 It is a specific flow chart of the forging piece cooling in the embodiment of the present invention, Figure 4 It is a schematic diagram of the structure of the cooling box 1. Figure 1-Figure 4 The specific steps of the forging process of the shank alien wheel are described in detail:

[0046] S1, blanking, cutting the original billet into a billet of the required length through a shearing machine;

[0047] S2, heating, using an intermediate frequency induction heating furnace to heat the billet, and the heating temperature is 980-1000℃;

[0048] S3. Sub-hot extrusion, using a single-point press for sub-hot extrusion forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com