Metal wire material additive equipment and material additive method based on alternating magnetic field

A technology of alternating magnetic field and metal wire, which is applied in the field of metal additive manufacturing, can solve the problems of difficult preparation of metal powder, high price, low energy efficiency of laser light source, etc., and achieves low production cost, reduced material cost, and excellent wire structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

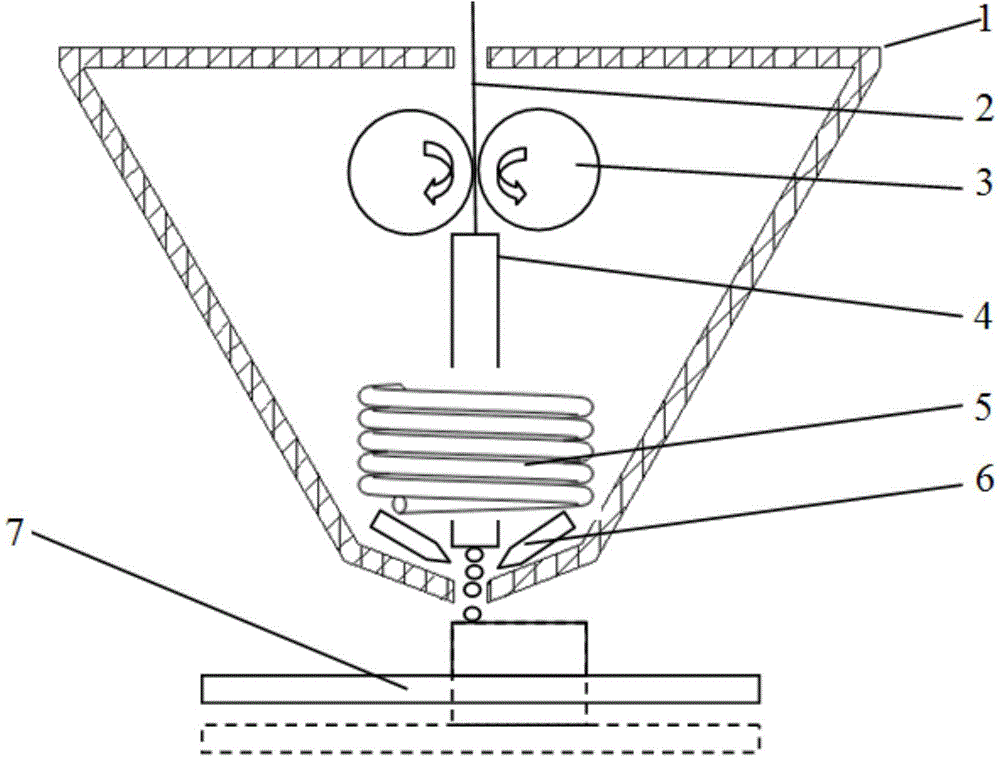

[0026] The structure of the wire material additive equipment based on the alternating magnetic field provided by the present invention is as follows: figure 1 As shown, it includes at least a numerical control device, a substrate 7 and a deposition head. Both the substrate 7 and the deposition head are installed on the numerical control device and can move under the control of the numerical control device. The substrate 7 is located below the deposition head.

[0027] The deposition head includes a shielding shell 1 and a wire wheel installed on the shielding shell 1. A metal wire 2 is wound on the wire wheel. The metal wire 2 is a pure metal or alloy material with a diameter of 0.1-0.5mm. In this embodiment The diameter thereof is 0.2mm. The characteristic of the metal wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com