Device and method for measuring heat exchange coefficient of interface in gas quenching process

A technology of interface heat transfer coefficient and gas quenching, which is applied in the preparation of test samples and thermal development of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

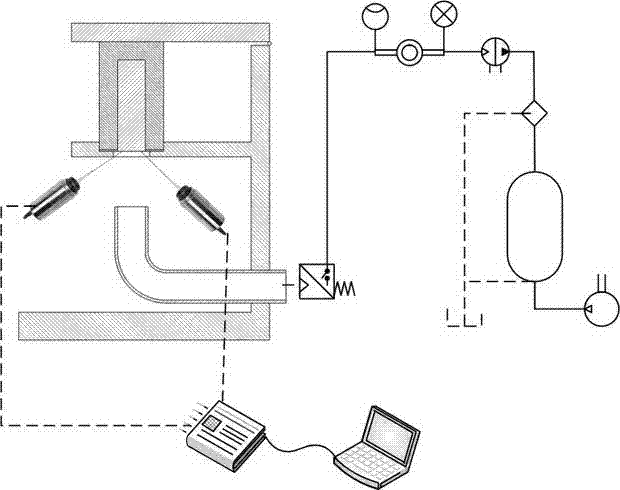

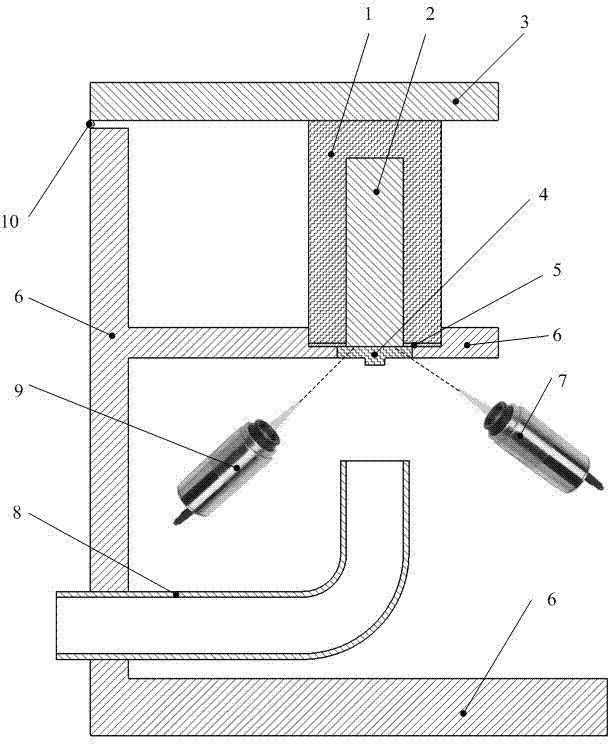

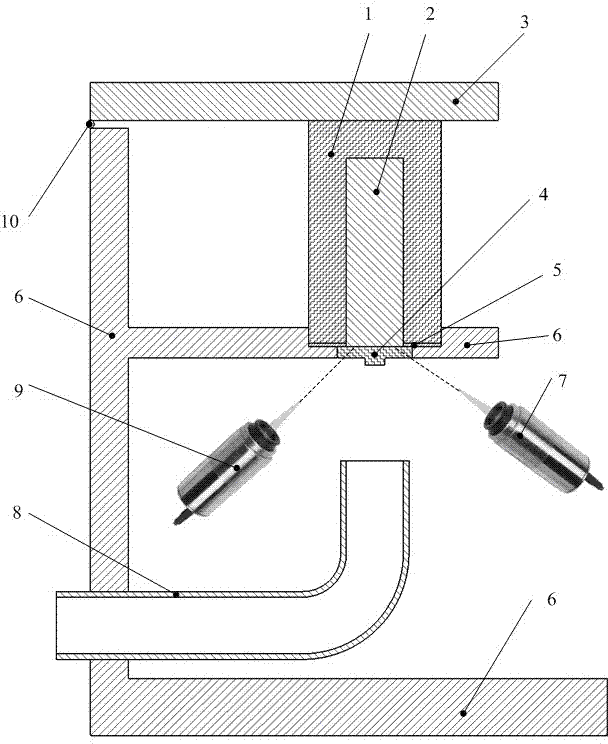

[0069] A device for measuring the interface heat transfer coefficient between quenched parts and gas in the process of gas quenching, including a sample fixing device, a temperature data acquisition device and a high-pressure gas supply device:

[0070] The sample fixing device includes a sample fixing frame 6 and a sample heat preservation device, the sample fixing frame 6 is provided with a placement hole, and the sample heat preservation device is located in the placement hole. Described sample heat preservation device comprises sample heat preservation cover 1, and the open end of described sample heat preservation cover 1 is provided with sample end insulation plug 4; A baffle 5 is provided, the size of the baffle 5 is consistent with the size of the opening end of the sample insulation cover 1, and the thickness of the baffle 5 is 1.5-2mm. The placement hole includes a placement hole I for placing the sample insulation cover 1 and a placement hole II for placing the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com